Consistency in secondary packaging systems ensures that every package undergoes the same processes and meets the same standards. This uniformity is crucial for meeting product safety standards, streamlining workflows, and delivering high-quality product loads to your customers.

You can rely on your packaging process to function seamlessly alongside every other part of your workflow when it delivers consistently clean, stable, and efficient results. Keep reading to learn more about the importance of consistency in packaging systems and how to build a reliable packaging workflow.

Consistency Improves Product Safety

Improved product safety is one of the most significant advantages of a consistent packaging workflow. An inconsistent packaging process leads to mistakes—such as uneven stretch wrapping or inadequate containment force—that leave your product loads vulnerable to breaking, tipping, and other damage during transit. This damage can lead to higher return rates and a decline in your company’s reputation. Customers who receive damaged product loads are unlikely to make repeat purchases and may even leave negative reviews, which can deter potential buyers.

Furthermore, uniform packaging makes it easier to identify and address potential weak points, ensuring greater protection against damage. A consistent workflow helps you to continuously improve your processes and deliver higher-quality results to your customers.

Fewer Mistakes, Faster Workflows

Consistency in packaging can streamline operations by minimizing mistakes and keeping products moving smoothly through your packaging line. Efficiency leads to faster turnaround times and lower labor costs. The result is a faster, more efficient, and more reliable workflow that gives your business a competitive edge.

Better Control With Automated Packaging

Prioritizing automation over manual processes is one of the best ways to achieve consistency in your packaging workflow. Automated packaging systems reduce the likelihood of human error and ensure that every package meets the same high standards of quality, stability, and safety. Investing in modern packaging equipment and software can streamline operations and improve overall efficiency.

Furthermore, automated packaging equipment gives you complete control over your packaging specifications. Therefore, you can customize your packaging process to perfectly suit every product that moves through your facility, giving you the ability to balance consistency with flexibility for an efficient, reliable workflow.

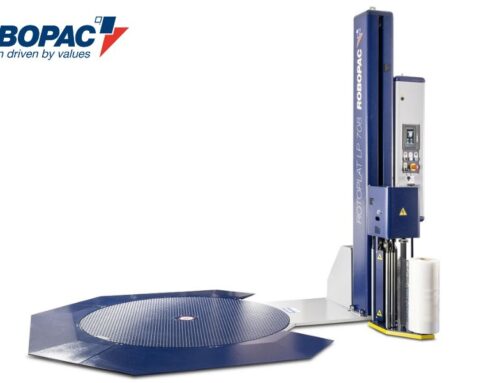

Achieve Consistency With Robopac USA

Consistency in packaging systems is important for ensuring product safety, enhancing operational efficiency, and building a strong reputation as a dependable supplier. See how the right products can bring consistency and reliability to your workflow when you invest in rotary arm stretch wrapper machines and other elite secondary packaging equipment from Robopac USA.