When it comes to packaging, companies face the difficulty of minimizing costs and material waste while maintaining product safety and meeting regulatory requirements. Businesses can address these challenges by rethinking how they package and deliver products. See the most impactful ways you can navigate supply chain challenges with advanced packaging.

Use Smart Packaging Technology

Smart packaging technology, such as RFID tags and QR codes, provides more than just a way to label shipments. These tools enable real-time tracking, allowing businesses to monitor their goods throughout the supply chain. This level of visibility improves inventory management and reduces the risk of delays and losses caused by misrouted or misplaced items.

Beyond providing better tracking, smart packaging lets teams make data-driven decisions. For example, knowing where a shipment is at all times can help companies reroute goods to meet shifting deadlines or demand changes. These capabilities are essential for improving efficiency and keeping supply chains resilient.

Optimize Packaging Design

Revisiting your packaging design can have a massive impact on your logistics costs. Compact and lightweight designs minimize wasted space, letting you ship more units on fewer pallets or in fewer shipments. At the same time, improved designs don’t need to sacrifice durability, ensuring goods stay protected in transit.

This shift also addresses environmental and operational priorities. Lighter loads require less fuel for transportation, reducing both costs and carbon footprints. Meanwhile, simplified designs increase efficiency in the warehousing and packing process, making workflows smoother.

Leverage Automation in Packaging

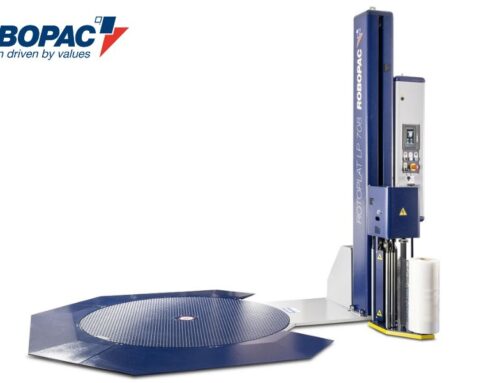

Automated packaging systems are revolutionizing production lines by reducing inefficiency, ensuring consistency, and offering scalability. Investing in semi-automatic and automatic packaging machinery streamlines operations and ensures more robust packaging protection.

Automation is equally effective for companies with smaller operations. Turntable stretch wrappers secure loads by wrapping them with stretch film while rotating them on a turntable, making them a practical choice for a wide range of industries. They cater perfectly to small and medium-volume packaging demands. With compact models available, these machines can fit into tighter spaces without compromising efficiency.

Reducing Inefficiency

Inefficiencies in packaging operations often lead to delays, bottlenecks, and rising labor costs. Automating repetitive tasks, such as handling, sorting, and packing items, reduces dependency on manual processes. Solutions like robotic arms and conveyor systems can complete these tasks faster and with greater precision. By implementing automation, businesses can streamline their operations, cut costs, and significantly boost productivity, ensuring smoother workflows and faster turnaround times.

Ensuring Consistent Packaging

Packaging inconsistencies can compromise product quality, leading to potential damage during transit, which frustrates customers and increases returns. Automation can address this challenge by using machines programmed for precision in wrapping, sealing, and labeling. These systems maintain uniformity and package every product to exact specifications. Consistent packaging improves product protection and customer satisfaction and enhances brand reliability by reducing the chances of shipping damaged goods.

Scaling Production

Fluctuating demand, especially during peak seasons, can overwhelm traditional packaging systems and delay deliveries. Automation provides a scalable solution with flexible systems capable of handling increased production volumes without added strain. Businesses can quickly adapt to changing demands while maintaining efficiency. This scalability ensures timely delivery, keeps operational costs in check, and prevents disruptions, enabling companies to sustain customer satisfaction and stay competitive.

Monitoring Performance

Integrated monitoring systems in advanced machinery help businesses navigate supply chain challenges with better insight into their packaging operations. Robopac USA’s R-Connect provides unparalleled visibility into machine operations with tools to monitor material usage, machine conditions, and production metrics. With this data, businesses can identify inefficiencies, gain insights into how individual machines are working, and achieve greater consistency across operations.

Use Protective Packaging Innovations

Protective packaging is critical for businesses shipping fragile, perishable, or high-value goods. Innovations like air cushioning, shock-absorbing materials, and temperature-controlled packaging ensure that products arrive intact and in top condition. These solutions prevent damage and protect your reputation.

Investing in protective options reduces disruption to the supply chain caused by damaged goods. Minimizing returns and replacements saves costs and improves customer satisfaction, creating a win-win for businesses and their clients.

Standardize Packaging Across Products

Standardizing packaging means using uniform materials, sizes, and designs across all or most of your product packaging. This could involve choosing a consistent box size, the same type of cushioning material, or standard labeling layouts for different products. When businesses standardize packaging, they make processes like storage, shipment planning, and working with logistics partners much more organized and efficient. It also reduces the chances of errors during packing, leading to faster workflows and fewer disruptions in the supply chain.

Many companies can adopt this approach, though those with diverse product lines or highly specialized packaging needs may face challenges. To start, companies can analyze their product range and identify areas to streamline packaging without compromising product safety or branding. Work closely with suppliers to find materials and designs that can serve multiple product types. Additionally, testing standardized packaging on a smaller scale before a full rollout can help you identify any potential issues and ensure both efficiency and reliability.

Use Tamper-Evident Packaging

Tamper-evident packaging is a type of packaging designed to show clear signs that someone has opened or interfered with it. Common features include seals, shrink-wraps, or security bands that break or change appearance when tampered with. These visible safeguards enhance safety by assuring customers that the product they’re purchasing is intact and untouched. This transparency gives consumers confidence in the quality and safety of the products they buy.

Tamper-evident packaging also deters theft and fraud by making it harder for bad actors to alter or steal from a product. For businesses, this reduces fraudulent returns and reinforces the brand’s reputation for delivering secure, high-quality goods. By protecting product integrity, tamper-evident packaging helps companies maintain their brand image.

Invest in Predictive Analytics

Predictive analytics uses data, algorithms, and machine learning to predict future outcomes based on historical data. Sensors and tracking systems gather real-time data on packaging line performance, including speed, efficiency, and any bottlenecks. Software platforms analyze this data to identify patterns and predict future trends, such as demand fluctuations or potential disruptions.

Predictive analytics reduces waste, ensures you always have packaging materials available when needed, and prevents overproduction or underproduction. It also addresses common challenges like last-minute order changes or unexpected shortages. Ultimately, it empowers businesses to make informed decisions that save time, money, and resources.

Advanced packaging solutions combine technology, innovation, and strategic design. Smart packaging and predictive analytics provide valuable data for better decision-making, while automation ensures efficiency and consistency across operations. Precision packing and tamper-evident packaging protect products and company reputations, reducing waste and customer complaints. Together, these approaches streamline processes, cut costs, and create dependable supply chains.