Labor shortages are a critical challenge for businesses, especially in industries reliant on repetitive, manual tasks like pallet wrapping. Finding and retaining workers for these physically demanding roles is no easy feat. Thankfully, automation offers an effective solution to this problem. Learn how addressing labor shortages with automatic stretch wrappers enhances efficiency and safety.

Reduces Dependence on Physical Labor

One reason businesses turn to automation is to alleviate the strain on their workforce. Automatic stretch wrappers take over the repetitive task of wrapping pallets, reducing the reliance on manual labor. This frees up workers to participate in more critical operations, allowing businesses to reallocate their team members strategically.

Automatic stretch wrappers perform the following essential tasks:

- They wrap pallets with consistent tension to ensure secure and uniform loads.

- They adjust film usage to optimize material efficiency and minimize waste.

- They apply pre-programmed wrapping patterns to meet specific packaging requirements.

- They detect pallet dimensions and adjust wrapping settings automatically.

- They seal film ends tightly to prevent unwinding during transportation.

- They handle different pallet sizes and configurations without needing manual adjustments.

- They monitor and stop operations in case of film breaks or obstructions.

- They maintain speed and accuracy even under high-demand conditions.

Additionally, by reducing the physical strain on employees, companies create a more balanced workload, contributing to higher overall employee satisfaction. The time-saving benefits mean that employees can focus on more skill-intensive tasks.

Boosts Operational Efficiency

Labor shortages can cause operational delays, but automatic stretch wrappers address this problem by delivering consistent performance at speeds manual methods cannot match. They wrap pallets faster and with greater precision, maintaining high productivity even with a reduced workforce. This efficiency is particularly valuable during peak demand periods or when staffing is unpredictable.

Automatic stretch wrappers operate seamlessly without the need for breaks or downtime, which keeps productivity levels consistent throughout the workday. This dependable performance results in quicker turnaround times, helping businesses keep pace with operational deadlines.

Enhances Product Quality

Poorly wrapped pallets are a leading cause of product damage during transportation, costing businesses time and money. Labor shortages can lead to overburdened workers rushing through pallet wrapping tasks, increasing the likelihood of uneven or unsecure wrapping. Reduced workforce availability also means fewer hands to maintain quality control, resulting in inconsistent load protection and potential product damage.

Automatic stretch wrappers help solve this issue by applying even, secure wrapping every time. This uniformity minimizes the risk of damaged goods so that items arrive at their destination intact. These machines also help businesses maintain high standards of quality control. By eliminating variations caused by human error, companies can consistently deliver well-protected products and improve customer trust and satisfaction.

Reduces Turnover Pressure

Tedious and physically demanding jobs contribute to high employee turnover rates. High employee turnover disrupts workflows, leading to delays and inconsistencies in meeting production targets. Additionally, businesses face increased costs for recruiting, hiring, and training new workers, which can strain resources and reduce overall efficiency.

Stretch film wrapping machines address this issue by taking over the menial and exhausting aspects of the job. The reduced reliance on recruiting allows businesses to save time and money typically spent on hiring and onboarding new employees. Additionally, it takes less time to train new hires on how to operate user-friendly automatic stretch wrappers compared to outdated equipment.

Saves on Labor Costs

Labor shortages usually lead to higher wages and payroll expenses, but automatic stretch wrappers offer a practical solution. These machines require fewer employees to handle pallet wrapping, allowing businesses to reduce overall labor costs. The investment in automation can quickly offset payroll expenses while maintaining high productivity.

Additionally, businesses that invest in automation benefit from long-term financial savings. Reliable machines lead to fewer disruptions, reducing costs associated with inefficiencies and human error in manual processes.

Minimizes Downtime

Insufficient staffing can create bottlenecks, slowing down operations across the board. Automatic stretch wrappers eliminate this issue by ensuring that vital tasks like pallet wrapping remain on schedule, even when labor shortages occur. Their consistent operation minimizes downtime and keeps workflows running smoothly.

The uninterrupted performance of automated systems is especially helpful during periods of increased demand. Businesses can maintain continuous operations regardless of fluctuating workforce availability, making sure customer commitments are met without delay.

Improve Performance With R-Connect

With Robopac USA’s R-Connect monitoring system, you can take full control of your stretch wrapping operations and drive better results. The system provides a clear view of machine performance, helping you identify needs before they disrupt production. You can track key details like film usage and machine condition to optimize your processes and cut down on waste. By using advanced analytics, you can make informed changes that boost productivity and reduce downtime, even in the face of labor shortages.

Scales Easily With Demand

Expanding operations often require additional effort, but labor shortages make hiring a challenge. Automatic stretch wrappers offer a scalable solution because they can handle workload fluctuations without the need to hire more workers. This makes them an excellent option for growing businesses.

Whether demand spikes during the holiday season or with business growth, these machines can keep up with operational requirements effortlessly. Scalability provides businesses with flexibility and reduces stress during times of transition or expansion.

Fits Your Needs

Stretch wrap machines are designed to meet the unique demands of medium- and high-volume facilities, making them an adaptable solution for addressing labor shortages. With options available at various price points, businesses can find a stretch wrapper that fits their budget without compromising on performance. These machines are also capable of handling different throughput levels for seamless integration.

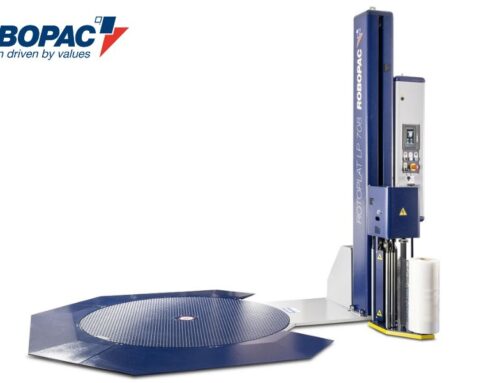

Automatic stretch wrappers come in a range of configurations to meet load processing requirements and fit into facility spaces easily. Vertical stretch wrappers can process most loads and are available in turntable, rotary arm, and rotary ring configurations, while horizontal stretch wrappers are designed for long items like lumber or pipes. Whether you process irregularly shaped loads, diverse load types, or standard pallets, there’s a stretch wrapper that’s perfect for your business.

Automatic stretch wrappers help create more sustainable operations. Implementing these machines tackles inefficiencies, preserves product integrity, and eliminates financial strains tied to maintaining a large workforce. They also offer flexibility in scaling up or down as needed, making them an ideal choice for both growth and adaptability. If your business is facing labor challenges, invest in automatic stretch wrappers to streamline your operations.