The Internet of Things (IoT) has become a buzzword in various industries, and it is quickly becoming a fundamental part of the packaging industry. IoT refers to the network of interconnected devices and systems that communicate with each other, collect data, and provide real-time insights. In the packaging industry, IoT is revolutionizing how companies package, track, and manage their products throughout the supply chain.

Companies with a comprehensive knowledge of the impact IoT has on the packaging industry can use these solutions within their own workflows and gain a competitive advantage for themselves and their customers. Learn more about the key benefits and opportunities IoT presents for packaging lines and supply chains with this overview.

Traditional Challenges in the Packaging Industry

The packaging industry has long faced numerous challenges that hinder efficiency and productivity. One of the primary issues is the lack of real-time visibility into the supply chain. Traditional packaging processes often rely on manual data entry and outdated systems, leading to delays, errors, and increased costs.

Additionally, the industry grapples with high levels of waste and inefficiency due to inadequate inventory management and inaccurate demand forecasting. These challenges not only affect profitability but also have a negative impact on sustainability efforts. However, with the advent of IoT, the packaging industry is poised for a significant transformation.

How IoT Is Revolutionizing Packaging

IoT systems work by connecting physical devices—such as packaging machines, sensors, and RFID tags—to the internet. These devices collect and transmit data, allowing packaging companies to monitor and control various aspects of the packaging process in real time.

IoT also enables seamless integration with other systems, such as warehouse management and transportation logistics, streamlining the entire supply chain. By leveraging IoT, packaging companies can achieve greater accuracy, speed, and cost savings while delivering superior customer experiences. Below are just a few examples of the impact IoT has already made on the packaging industry.

IoT and Efficiency

Efficiency is a critical factor in the packaging industry, and IoT is streamlining workflows to boost productivity. IoT-enabled packaging machines can automate repetitive tasks, such as labeling, sealing, and sorting, reducing the need for manual labor and minimizing errors.

Real-time data from IoT devices can also provide insights into machine performance. This helps managers identify potential issues before they lead to costly downtime. This proactive maintenance approach ensures that packaging lines operate smoothly and efficiently, maximizing productivity and reducing costly interruptions.

Furthermore, IoT can enable predictive analytics, allowing companies to anticipate demand patterns and optimize production schedules. By leveraging IoT for efficiency improvements, packaging companies can achieve higher output, lower costs, and improved overall operational performance.

Visibility and Tracking

Another significant advantage of IoT in the packaging industry is enhanced visibility and tracking. IoT-enabled devices provide real-time updates on the location and status of shipments, allowing businesses to monitor their products from production to delivery.

This increased visibility not only improves supply chain management but also helps in identifying potential issues before they escalate. For instance, if a shipment is delayed or deviates from its intended route, IoT sensors can immediately alert the relevant stakeholders, enabling them to take corrective action. This level of transparency builds trust with customers, who can track their orders in real time and receive accurate delivery estimates.

Analysis and Insights

IoT doesn’t stop at collecting data; it goes a step further by analyzing this information to provide valuable insights. By leveraging IoT analytics, companies can gain a deeper understanding of their operations and identify areas for improvement.

For example, data from IoT sensors can reveal patterns in equipment usage, highlighting the need for maintenance or replacement. This proactive approach helps optimize preventative maintenance schedules, preventing costly downtime and extending the lifespan of machinery.

IoT analytics can also optimize supply chain processes by identifying bottlenecks and inefficiencies, allowing businesses to implement targeted solutions and continuously excel in their operations.

IoT Boosts Consumer Engagement

One of the most significant benefits of IoT in packaging is the enhanced consumer engagement it offers. With IoT-enabled packaging, companies can provide consumers with interactive experiences and personalized information.

For example, smart packaging can include QR codes that consumers can scan using their smartphones to access product details, usage instructions, and promotional offers. This not only adds value to the consumer but also enables companies to gather valuable data on consumer preferences and behavior.

By leveraging this information, packaging companies can tailor their marketing strategies, create personalized experiences, and improve customer satisfaction, ultimately driving brand loyalty and repeat purchases.

Environmental Opportunities

IoT is also playing a crucial role in revolutionizing sustainability efforts within the packaging industry. Traditional packaging processes often result in excessive waste and environmental impact. However, with IoT, companies can implement smarter packaging solutions that minimize waste and promote eco-friendly practices.

For instance, IoT-enabled sensors can monitor the condition of perishable goods during transportation, ensuring optimal storage conditions and reducing spoilage. Additionally, IoT can enable better tracking and monitoring of packaging materials, allowing companies to optimize material usage, enable smart, automatic ordering, and reduce overproduction.

By adopting IoT-driven sustainability initiatives, packaging companies can not only reduce their carbon footprint but also meet the growing consumer demand for environmentally conscious products.

Challenges With IoT Systems

Despite its numerous benefits, implementing IoT in the packaging industry is not without challenges. Security is a major concern, as IoT devices are susceptible to cyberattacks. Protecting sensitive data and ensuring the integrity of IoT systems—and a company’s network as a whole—is crucial for maintaining trust and reliability.

Another challenge is integration. Many companies find it difficult to integrate IoT with their existing systems and processes. Ensuring compatibility and seamless communication between different devices requires careful planning and execution. Companies must work with teams across the board to optimize new technology, communicate changes, and support employees and workflows during transitional phases.

The Future of Packaging With IoT

The future of packaging is undoubtedly intertwined with the advancements in IoT technology. As the packaging industry continues to evolve, IoT will play an increasingly vital role in driving innovation, efficiency, and sustainability. By harnessing the power of IoT systems, facilities can overcome traditional challenges, enhance consumer engagement, and contribute to a greener future.

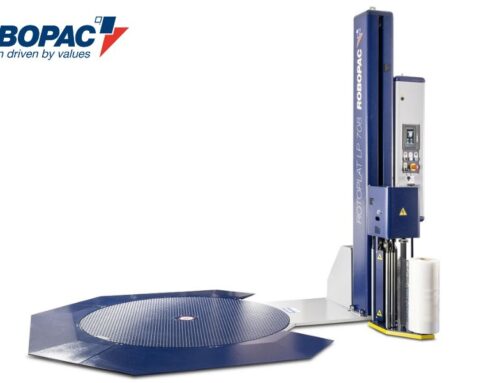

The integration of IoT into packaging processes is not just a trend but a necessity for staying competitive in today’s rapidly changing market. Equip your workflows with cutting-edge equipment that keeps your processes visible and efficient when you partner with Robopac USA as your stretch wrapper manufacturer. Talk to our team today to find the optimal secondary packaging solutions for your company’s specific needs.