Selecting the right stretch wrapper manufacturing partner means more than just checking an item off your equipment list. This decision can impact the efficiency, safety, and cost-effectiveness of your entire operation. Before you begin your search, we’ll explain what to avoid when choosing a stretch wrapper manufacturer.

Key Considerations for Choosing a Stretch Wrapper Manufacturer

Before making any decision, examine your specific operational needs. Start by addressing key factors such as the type of products you’ll be wrapping and your current methods. For instance, if your loads are particularly heavy or oddly shaped, you’ll need equipment that can manage those characteristics safely. Determine how many loads you wrap daily and evaluate any issues with shipping damage to identify whether a semi-automatic or fully automatic solution is best for your operation.

It’s also important to review the specifications of your pallets, such as their size and weight. For example, lighter loads may require a stretch wrapper with a top platen to stabilize the items during the wrapping process. Meanwhile, taller or bulkier loads necessitate specific mast heights or wrap zones for safety compliance.

Common Mistakes To Avoid When Choosing a Manufacturer

When searching for a stretch wrap machine manufacturer, there are many common mistakes you’ll want to know about so that you can avoid them. By understanding what to avoid when choosing a stretch wrapper manufacturer, you can find the ideal partner for your business and process.

Avoid Focusing Solely on Price

When investing in a stretch wrapper, many businesses focus only on price and neglect other critical factors. While cost is obviously important, this short-term thinking can result in inefficiencies and higher costs over time. Consider prioritizing long-term operational efficiency over saving a few bucks in the present.

Prioritize Safety

Another common mistake is overlooking safety and throughput capacity. Manual pallet wrapping carries accident risks, which manufacturers need to address in their equipment design.

Consider Film Consumption Efficiency

Film consumption is a major ongoing cost that many manufacturers overlook. The right stretch wrapper can reduce film usage significantly, which translates to impressive savings on resources over time. Ignoring this factor can lead to unnecessary expenses.

Watch Out for Proprietary Parts

Proprietary components are another hidden cost that you can’t overlook. Some manufacturers use complex, expensive parts that are hard to replace or repair, especially if they go out of production. Opt for equipment with readily available, non-proprietary parts to avoid supply chain issues.

Factor in Delivery Timelines

If something goes wrong and you need a replacement part or service, you want a partner you can trust to get the job done quickly. Delivery delays can disrupt your workflow, causing bottlenecks and breaking deadlines. A reliable manufacturer should provide clear delivery timelines and ensure they align with your schedule.

Lay the Foundation for Long-Term Success

Choosing the right stretch wrapper manufacturer is about finding a partner that aligns with your operational goals. By identifying your specific needs and selecting a manufacturer that prioritizes efficiency, safety, and scalability, you can optimize your packaging process and achieve long-term success.

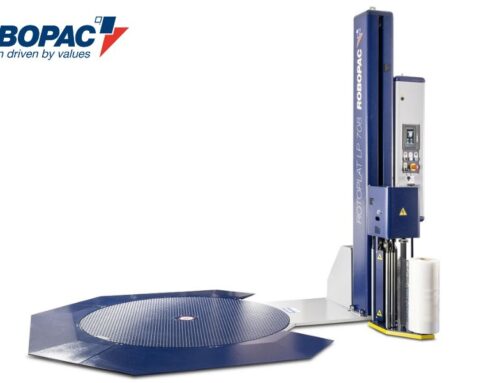

If you need to find a stretch wrapper manufacturer, consider Robopac USA. Our superior machine technology and excellent customer service make us an ideal partner to work with. View our equipment and contact our staff to learn more today.