The modern market demands speed and precision. For any company involved in packaging or logistics, whether it’s food, electronics, or consumer goods, staying competitive often means moving toward automation to reduce costs and improve productivity.

But how do you know when it’s time to make the change from manual processes to automation? By paying attention to your packaging line, gathering employee feedback, and running regular audits, you can make sure your workflow remains flexible, efficient, and effective. Stay in the know with these signs that it’s time to consider packaging automation.

You’re Dealing With High Demand

When demand surges, your company may have trouble keeping up with production using manual methods. This is where packaging automation can be a game-changer. Automated systems rapidly scale up operations to meet high demand without the need for additional labor. Automated systems also provide flexibility in meeting diverse customer requirements. Whether it’s varying package sizes or specific labeling needs, automation can adapt quickly, allowing your company to offer customized solutions without compromising on speed or quality.

In particular, the general rule for stretch wrapping is that if you are managing more than 10 loads per day, it’s more cost-effective to rely on automatic or semi-automatic stretch wrapping equipment. By incorporating automation, your company can ensure that its packaging processes keep pace with production, eliminating costly delays. This ability to scale efficiently gives your business a competitive edge, enabling you to fulfill larger orders and expand your market presence.

You Want To Reduce Labor Costs

Labor costs can significantly impact your company’s bottom line, particularly in the packaging sector. If you are manually stretch wrapping (hand wrapping) more than 10 pallets per day, it pays to automate. Packaging automation offers a solution by reducing the reliance on manual labor, which can be both expensive and inconsistent. Automated systems can operate around the clock without fatigue, ensuring a continuous flow of packaged goods and reducing the need for overtime or additional shifts.

Furthermore, automation can free up human resources for more strategic roles within your company. Employees previously tasked with repetitive and mundane packaging duties can now focus on areas like quality control, innovation, and customer service. This shift not only boosts morale but also adds value to your organization, fostering a culture of growth and development.

You Want To Improve Packaging Consistency

Consistency is key in packaging, as it directly impacts the consumers’ perception of product quality. Automated stretch wrapping systems excel in delivering consistent results, ensuring that every package meets the same high standards for containment force to ensure your products make it to their final destination without primary packaging or product damage. This uniformity is particularly important if your business is aiming to build trust and loyalty among its customer base.

Inconsistent packaging can lead to product damage during transit, affecting both the customer experience and your company’s reputation. Automation minimizes these risks by applying precise and uniform techniques, such as stretch wrapping, to secure products effectively. This reliability reduces return rates and enhances customer satisfaction, which is a crucial factor for long-term success.

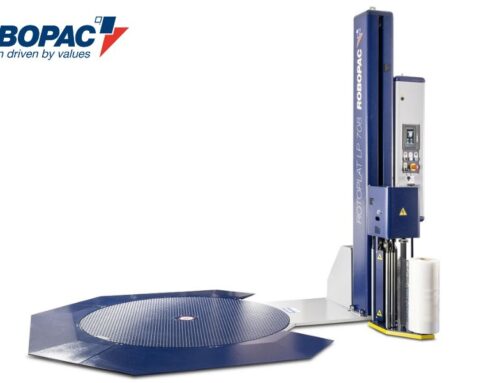

If you are considering packaging automation for your business, let Robopac USA help. Explore our range of automatic and semi-automatic stretch wrappers to find the best solutions for your workflow.