A crucial part of building a successful packaging workflow is using the right materials. When it comes to secondary packaging, that usually means utilizing shrink wrap or stretch wrap. Both solutions serve the same purpose—using plastic to wrap and secure product loads—but they involve different materials and processes.

How do you decide which one is right for your business, then? Learn more about the differences between shrink wrap and stretch wrap to see how both solutions can benefit your packaging workflow.

An Introduction to Shrink Wrap

Shrink wrapping is a process that uses shrink film, a thin, plastic film that contracts with heat. In packaging workflows, employees loosely cover a product load with shrink film, then use heat shrink sealers to secure the plastic and create a tight seal around the products. This type of film is used by case packing equipment, including shrink wrappers.

There are different types of shrink wrap materials that offer various benefits for specific product applications. Polyolefin wrap is the most common type of shrink wrap. Its strength and durability allow for a lasting seal and tough, puncture- and tear-resistant coverage.

Polyvinyl chloride (PVC) shrink wrap is a lightweight, cost-effective wrap material. It’s flexible and easy to use, but it offers incredible durability and tear resistance, making it ideal for heavy or bulky products, such as wood or metal materials. The downside of PVC shrink wrap is that it contains chemicals that can be harmful in closed spaces with poor ventilation. Always use PVC shrink wrap in an open area with proper ventilation, and be careful in choosing the products you wrap with it.

Polyethylene shrink wrap also offers dependable strength and integrity when wrapping large or bulky products. This makes it an increasingly popular alternative to PVC shrink wrap despite its greater cost. Polyethylene wrap is also thick and firm enough to allow for customization like printed designs, which helps companies create more personalized and brand-relevant packaging.

Advantages of Shrink Wrap

There are many reasons for companies to use shrink wrap in their secondary packaging workflows. The tight seal that shrink wrap creates offers incredible security and protection for product loads. It keeps out dust and bacteria, making it a reliable way to protect products from contamination.

Shrink wrap is also an effective solution for preventing water damage. You can even create well-ventilated loads with shrink wrap, allowing you to preserve your products without the risk of moisture and condensation buildup causing damage.

Shrink wrap is also an efficient packaging solution. It requires only one loose layer of plastic and a heat gun, shrink tunnel, or other form of shrink wrapping machine to achieve a tight, dependable seal on your products. This helps streamline your workflows while creating consistently secure and stable product loads.

Shrink Wrap Applications

To make the most of shrink wrap in your facility, you need to use the process that best matches your products and business demands. There are different styles of case packing machines—also known as shrink wrap machines—including lap sealers, bar sealers, and bundling machines.

Lap Seal Style Machines

Lap seal style machines utilize flat, single wound film to wrap products in a fast, efficient process. They’re ideal for mid- to high-volume facilities that need a fast and consistent wrapping solution. Lap sealing creates a lean seal that offers a sleek, attractive appearance that shows off the look and branding of the product itself. You can also use printed shrink wrap film with lap sealers to create a customized look for your products.

Sealing Bar Style Machines

Sealing bar style machines, on the other hand, wrap film around the product and use a bar to press down on the film and create a tight seal. Bar sealers are flexible enough to suit a variety of product packaging options, including film, pad and film, tray and film, and tray only product cases. You can find both automatic and semi-automatic bar sealers, allowing you to choose the right machine for your workflow demands.

Bundling Machines

You can also use bundling, a form of shrink wrapping that uses thicker film to bundle and stabilize multiple products at once. This creates a single, uniform package, making it great for multi-packs of items, such as food or beverage products.

An Introduction to Stretch Wrap

Like shrink wrap, stretch wrap is a form of plastic wrap that businesses use to package and protect products. Stretch wrap doesn’t require heat to create a seal, though. Instead, employees or machines wrap multiple layers of plastic around a load. The plastic clings to itself, creating a tight and secure wrap around the products.

The strength of the stretch wrap layers is known as containment force. By adjusting containment force—through adjusting the number of layers and the tightness of each layer—businesses can implement strong, safe, and protective wrapping for their product loads.

Advantages of Stretch Wrap

Stretch wrapping is a cost-effective, dependable way to secure product loads. The plastic wrap protects products from dirt, dust, and other forms of contamination. Some forms of stretch wrap even offer UV protection.

Businesses can also use stretch wrapping to keep product loads safe from water and moisture damage. Certain stretch wrap techniques, such as roping, also allow for ventilation, letting moisture-sensitive products—such as fresh produce—breathe and avoid condensation buildup as they move through the supply chain.

Another key benefit of stretch wrap is its versatility. With the right stretch wrapping machines, you can wrap any type of product load, including large loads of machinery, construction materials, furniture, and more.

Stretch Wrap Applications

Machine wrapping is the ideal way to use stretch wrap. Solutions like semi-automatic stretch wrapping machines wrap product loads faster and more consistently than manual applications. They’re strong enough to offer great pre-stretch, allowing your stretch wrap to go further. This helps save money on material costs and minimizes wasteful material in your packaging processes. Stretch wrap machines also offer the precision and customization to create the perfect level of containment force for each unique load that moves through your facility.

There are several types of stretch wrap machines, including turntable wrappers, rotary arm wrappers, and horizontal wrappers.

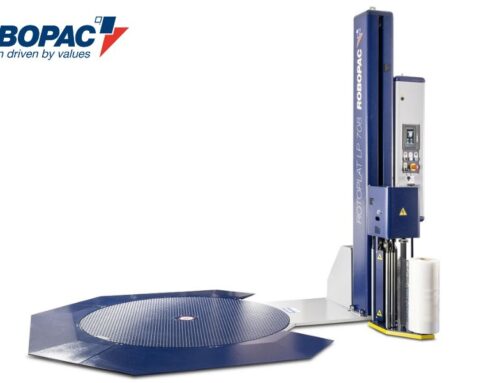

Turntable Stretch Wrappers

Turntable stretch wrap machines use a turntable to rotate a product load while wrapping it. This creates a fast and efficient wrap process that helps products move quickly through your facility. Turntable wrappers are ideal for stable loads that can handle the movement of the turntable.

Rotary Arm Stretch Wrappers

Think of rotary arm stretch wrappers as the opposite of turntable stretch wrappers. Instead of the pallet rotating, it stays stationary while a stretch wrap dispenser moves in circles around the product load. This type of wrapper is excellent for loads that are too heavy, too light, or too unstable to rotate.

Horizontal Stretch Wrappers

Some products don’t fit on a typical pallet, which means vertical stretch wrappers, like those mentioned above, won’t work. That’s where horizontal stretch wrappers come in. Long or oversized products, such as bundles of lumber, carpet rolls, and other similar materials, move horizontally along a conveyor belt and through the wrapper. The result is a secure bundle that will keep the products safe through the supply chain.

Finding the Best Solution for Your Business

Knowing the difference between shrink wrap and stretch wrap is key to using both effectively within your packaging line. Work with Robopac USA to optimize your workflows with the best secondary packaging equipment solutions for your business.