When it comes to optimizing your warehouse, automation is an invaluable investment. Businesses of all sizes can benefit from automated solutions, but many warehouse managers underestimate the value of implementing automated equipment, software solutions, and other innovations. Misinformation about where, when, and how facilities can use automation holds businesses back from realizing their full potential. Read on to bust some of the most common myths about warehouse automation and discover how these solutions can benefit your business.

Myth: Your Warehouse Is Too Small for Automation

Many people equate automation with expansive, high-volume systems that take up the entire warehouse floor. For smaller operations, this can be a waste of space and money, but automation means more than just comprehensive workflow solutions. Options like warehouse management systems benefit businesses of every size.

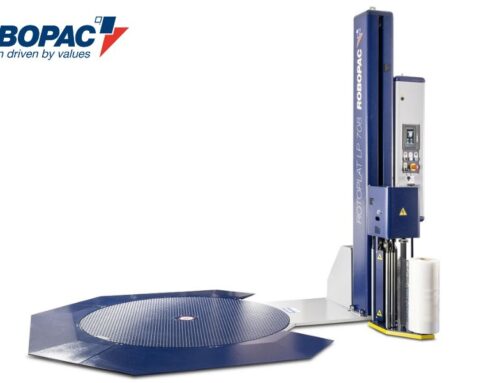

You can also implement smaller equipment solutions, such as investing in a single LGV or replacing manual stretch wrapping with an automatic or semi-automatic stretch wrapper. The vast range of automated solutions makes it easy for businesses to choose the systems that suit their needs, budget, and capacity while also allowing them to scale their automation to support future business growth.

Myth: Automation Is Too Expensive

One of the most common myths about warehouse automation is that it’s too expensive for small- to medium-sized facilities. Many companies worry that it will take too long to achieve a positive return on investment. Though automation comes with upfront costs, it also helps you cut labor costs, material expenses, product loss and waste, and more. Combined with the boost in efficiency, consistency, safety, and productivity, these savings help you generate a positive return. Automation also helps support long-term financial goals by minimizing downtime, improving scalability, and more.

Myth: Automation Risks Downtime

All equipment solutions experience downtime, but automation helps minimize issues and keep your workflow running smoothly. Monitoring systems, system analytics, smart maintenance tracking, and other tools help you stay on top of routine maintenance and any unexpected issues that arise. With this enhanced knowledge and visibility, you can address problems early and prevent costly, time-consuming downtime in the future.

Invest in the right automation for your business when you partner with the experts at Robopac USA. Visit us today to explore cutting-edge technology like our shrink wrap turntables and other secondary packaging equipment.