Stretch wrapping is an essential part of modern packaging and logistics. Stretch wrapping ensures product safety, stability, and cost efficiency during transit with industries requiring secure shipments, from food and beverage to metalworking. But not all stretch wrapping is the same.

Methods range from manual to fully automated systems, and understanding these options can help your business choose the best solution for its needs. In this blog, we’ll help you better understand the distinct methods of stretch wrapping, including manual wrapping, semi-automated, and fully automated wrapping machines. We explore how they work and their advantages so you can make an informed decision on an end-of-line packaging solution.

Introduction to Stretch Wrapping

Let’s review the basics of stretch wrapping and why it’s an important part of packaging, transport, and storage before we get into the various methods. Stretch wrapping involves covering a palletized load with stretch film and securing the items for shipment while protecting them from external factors, such as dirt, moisture, and movement during transit. The process uses a plastic stretch film that clings to itself, creating a stable packaged unit.

Stretch wrapping maintains product integrity during shipping and handling. It prevents goods from shifting, reduces the risk of damage, and ensures compliance with safety standards. Stretch wrapping reduces shipping costs and improves efficiency on the packaging line by stabilizing loads and reducing waste.

Manual Hand Wrapping: The Traditional Method

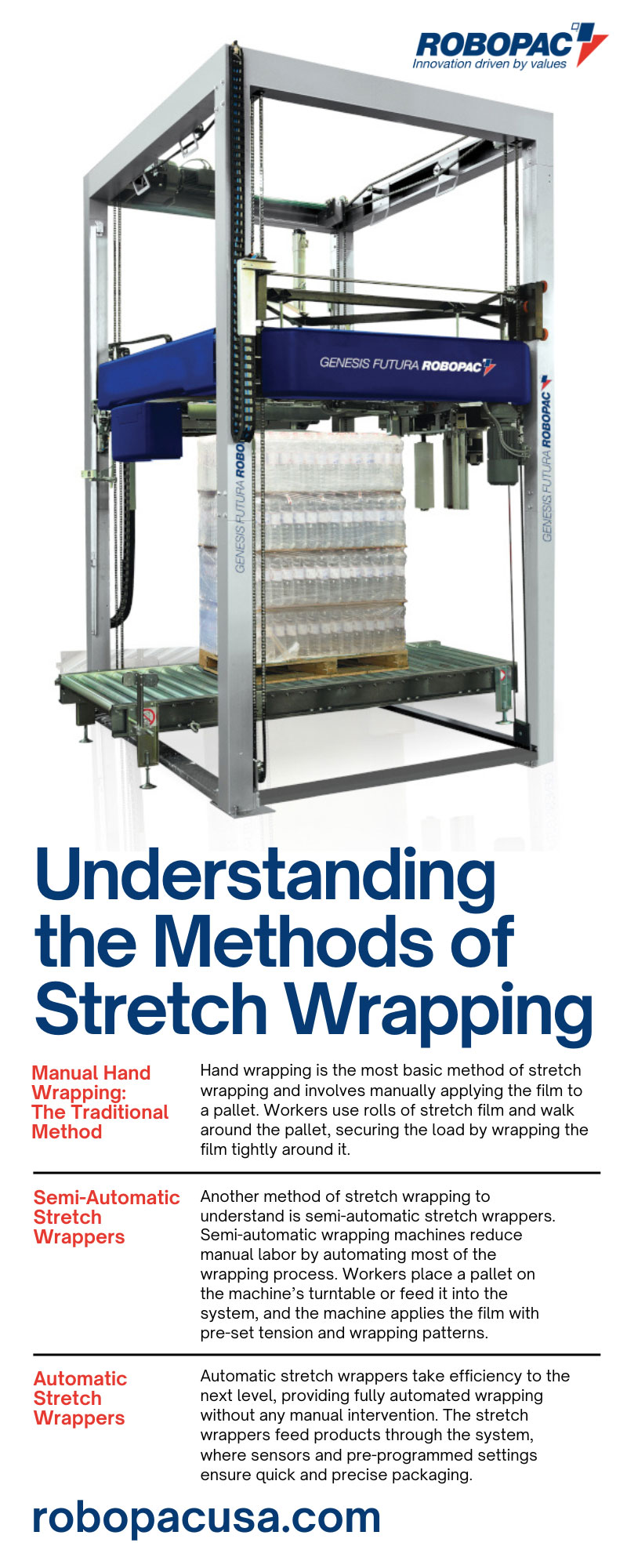

Hand wrapping is the most basic method of stretch wrapping and involves manually applying the film to a pallet. Workers use rolls of stretch film and walk around the pallet, securing the load by wrapping the film tightly around it.

Drawbacks of Manual Wrapping

While manual hand wrapping may seem cost-effective initially, it comes with several drawbacks that can add hidden costs. Its dependency on labor can mean inconsistent wrapping quality, leading to film waste and uneven film tension.

Labor Intensive and Unreliable

Hand wrapping requires significant physical effort, leading to worker fatigue and inconsistent results. No two workers will wrap a load the same way, which can compromise load stability.

Inconsistency in Wrapping

Manual wrapping presents a higher chance of incorrect wrapping, which can result in uneven film tension and leave some parts inadequately secured. This discrepancy can cause shifting or damage to products during transit.

Film Wastage and High Costs

Manual wrapping typically stretches the film by only about 10 percent, far below the 100-300 percent capacity of machine wrapping. This limited stretch leads to excessive film usage, increasing material costs over time.

Poor Ergonomics and Workplace Injuries

The repetition and labor of manual wrapping are also hard on laborers. The consistent hand wrapping and awkward bending and stretching pose serious ergonomic issues. Over time, poor ergonomics can lead to workplace injuries and a decrease in employee morale.

Labor Dependency

Finding reliable labor for manual hand wrapping can be a challenge, especially for larger operations requiring constant wrapping throughout the day. Automated wrappers are easy to find and can be up in running in no time.

Semi-Automatic Stretch Wrappers

Another method of stretch wrapping to understand is semi-automatic stretch wrappers. Semi-automatic wrapping machines reduce manual labor by automating most of the wrapping process. Workers place a pallet on the machine’s turntable or feed it into the system, and the machine applies the film with pre-set tension and wrapping patterns.

Advantages of Semi-Automatic Solutions

Semi-automatic wrapping machines provide many benefits over manual wrapping. They’re much more consistent and utilize more wrap without waste. Plus, many models can fit your specific needs.

Consistent and Reliable Wrapping

Semi-automatic machines ensure a consistent wrapping pattern and tension every time. This dependable and constant wrapping pattern improves load stability and minimizes the chances of damage during transit.

Pre-Stretch Capabilities and Cost Savings

Semi-automatic systems stretch the film before applying it, with pre-stretch levels ranging from 100 to 400 percent. This feature maximizes the use of the film, drastically reducing material waste and costs.

Different Models for Your Needs

Semi-automatic stretch wrappers come in various models to suit different applications. Whether you need a mobile model or one for elongated products, there’s a machine for you:

- Robotic models: Ideal for mobility, where the wrapper moves around the pallet rather than the pallet moving.

- Turntable models: A rotating base that spins the load while applying the film.

- Rotary arm models: The film carriage rotates around stationary pallets, suitable for heavier or unstable loads.

- Horizontal models: Designed for elongated products, such as wood panels or metal profiles.

Automatic Stretch Wrappers

Automatic stretch wrappers take efficiency to the next level, providing fully automated wrapping without any manual intervention. The stretch wrappers feed products through the system, where sensors and pre-programmed settings ensure quick and precise packaging.

Benefits of Automatic Systems

The advantages to utilizing automated stretch wrappers for your end-of-line packaging needs. They’re much faster than other methods without sacrificing consistency or wrapping quality.

High-Speed Capabilities

Automatic stretch wrappers are for high-speed operations and can wrap 30 to over 200 loads per hour. This speed makes them ideal for large-scale operations with constant packaging demands.

Versatile Models for Industrial Needs

Different models of automatic stretch wrappers can meet a range of industrial needs. Turntable models are ideal for standard pallet loads, while rotary arm models are best for higher-speed wrapping. Rotary ring models provide lightweight film applications with maximum speed, and horizontal models are for wrapping long, narrow items such as carpets or steel pipes.

Enhanced Efficiency and Throughput

Automated stretch wrapping systems streamline the packaging process to reduce the time spent wrapping each load. This increase in throughput allows operations to handle higher volumes with ease, leading to quicker turnaround times and improved productivity. By eliminating manual labor from the wrapping process, businesses can dedicate resources to other, more important tasks.

Material and Cost Savings

Automatic stretch wrappers stretch film efficiently, applying just the right amount for secure wrapping while minimizing waste. This precision reduces material consumption and drives down the costs of excess film usage. Over time, businesses will experience substantial savings, making automated stretch wrapping a cost-effective investment in both the short and long term.

Choosing the Right Stretch Wrapping Method

As stretch wrapper manufacturers, we can help you find the ideal wrapping method for your process. Manual hand wrapping offers a simple, low-tech solution but comes with drawbacks in efficiency, cost, and worker safety. Semi-automatic solutions bridge the gap, providing better consistency and cost savings while reducing labor demands. However, for large-scale and high-speed operations, automatic stretch wrappers are the most efficient and reliable solution, offering capabilities that adapt to various industrial requirements.

Consider your operation’s size, volume of loads, budget, and long-term goals for efficiency and sustainability when choosing the right stretch wrapping method. Semi-automatic systems are great for medium operations, while automatic solutions shine in high-volume, fast-paced settings.

Wrap Up Your Packaging Needs With Robopac USA

Stretch wrapping is more than a means to secure products; it’s a strategic step toward reducing costs and improving operational efficiency. Whether you’re running a small packaging line or a high-volume warehouse, selecting the right method can make all the difference.

Explore how automation can revolutionize your packaging operations. Contact our team today to find the best solution for your business needs and elevate your packaging game.