Load planning is more than just a technical term in the world of logistics and supply chain management. It is a critical component of packaging that ensures products reach their destination efficiently and safely. Understanding load planning can be a game-changer for businesses striving to optimize their operations and cut costs.

However, it’s not just about efficiency. Understanding the importance of load planning in packaging improves product load stability, employee safety, and so much more. Learn more about load planning, how it enhances the packaging process, and how to optimize your loads for shipment with this overview.

What Is Load Planning?

Load planning involves strategically arranging goods in a vehicle or container to maximize space and ensure safe transportation. This process considers various factors, such as the size, weight, and shape of packages. It is an essential aspect of packaging that helps businesses manage shipping costs, increase efficiency, and minimize risks during transit. Companies can achieve significant savings and improve their overall supply chain performance by optimizing product loads.

The Benefits of Load Planning in Packaging Efficiency

Effective load planning is crucial for establishing and maintaining a safe, efficient, and consistent workflow. By carefully organizing the placement of goods within a container, businesses can reduce wasted space, enhance load stability, and ensure they protect their items during transit. Careful organization minimizes the risk of damage and streamlines the packing process, making it more time-effective. Companies that prioritize load planning can experience smoother operations and enjoy the benefits of well-organized shipping procedures.

Increasing Cost Savings

One of the biggest reasons for understanding the importance of load planning in packaging is because of the cost savings it offers. By maximizing the use of available space within a container, businesses can reduce the number of shipments required, leading to lower transportation costs. This efficient use of resources translates to savings on fuel, labor, and time, all of which contribute to a healthier bottom line.

Companies that employ effective load planning techniques can also decrease the need for additional packaging materials, further cutting costs. By investing in load planning, businesses can optimize their resources and enjoy substantial financial benefits.

Improving Environmental Impact

Load planning can also have a positive impact on the environment. By optimizing the use of space within shipping containers, companies can reduce the number of trips needed to transport goods, resulting in lower carbon emissions. This reduction in fuel consumption helps businesses cut costs and contributes to a more sustainable supply chain.

Companies that prioritize environmental responsibility can use load planning as a tool to minimize their ecological footprint and demonstrate their commitment to sustainability. Businesses can make a big difference in preserving our planet by making small changes in their logistics processes.

Maximizing Cargo Space

Utilizing cargo space effectively is one of the primary goals of load planning. By arranging packages strategically, businesses can ensure they put to good use every inch of available space. Strategic arrangements also reduce the number of shipments required and prevent overloading and the associated risks.

Companies that make the most of their cargo space can transport more products in fewer trips, cutting down on transportation costs and increasing operational efficiency. Load planning allows businesses to make the most of their resources, leading to improved logistical performance.

Enhancing Load Stability and Product Safety

Load planning is also crucial for ensuring load stability and product safety. By considering the size, weight, and shape of packages, businesses can arrange items in a way that prevents shifting during transit. This careful organization minimizes the risk of damage to goods, reducing the need for costly claims and returns. When products arrive in excellent condition, customer satisfaction improves, and businesses can maintain a positive reputation. Load planning is a vital component of ensuring that shipments are safe and secure, providing peace of mind to companies and their customers.

Increasing Operational Efficiency

By optimizing the loading process, businesses can improve their overall operational efficiency. Load planning reduces the time it takes to pack and unload shipments, allowing companies to move goods more efficiently. This streamlined approach minimizes delays, ensuring that products reach their destinations on time. With effective load planning, businesses can enhance their supply chain performance and keep their operations running smoothly. Greater efficiency results in increased productivity and the ability to meet customer demands.

Improving Customer Satisfaction

Load planning can have a direct impact on customer satisfaction. Businesses can build trust and loyalty with their customers by ensuring that shipments arrive on time and in excellent condition. Companies that deliver their products in an appropriate amount of time and without damage can avoid costly returns and maintain a positive relationship with their clients. Load planning helps businesses provide a reliable service, encouraging repeat business and boosting their reputation. Satisfied customers are more likely to recommend a company to others, leading to increased sales and growth.

Meeting Industry Regulations

Load planning is essential for meeting industry regulations and safety standards. By organizing shipments in compliance with legal requirements, businesses can avoid fines and penalties. This adherence to regulations helps companies maintain a positive reputation and ensures that their operations run smoothly. Load planning is also important for preventing accidents and ensuring businesses transport their goods safely. By prioritizing load planning, businesses can stay ahead of regulatory requirements and focus on providing excellent service to their customers.

Factors Affecting Load Planning

Several factors influence load planning, including the size, weight, and shape of packages. These elements determine how businesses should arrange their products within a container to maximize space and ensure safety. Businesses must consider these factors when planning their loads to optimize the use of available resources. By understanding the unique characteristics of their shipments, companies can develop effective load planning strategies that enhance efficiency and protect their products.

Tools and Technologies for Load Planning

Various tools and technologies can assist businesses with load planning, ranging from manual methods to automated solutions. Traditional methods involve manual calculations and sketches, but this method is time-consuming and increases the chances of mistakes from human error. Modern solutions, such as advanced software and algorithms, improve accuracy and consistency to optimize load arrangements. These technologies help businesses streamline their processes, reduce human error, and save time.

By investing in the right tools, companies can enhance their load planning capabilities and improve their overall efficiency. The choice of technology depends on the business’s specific needs and resources, as finding the right solution is crucial for success.

The Importance of Continuous Improvement in Load Planning

Continuous improvement is essential for effective load planning. By regularly evaluating and refining their strategies, businesses can stay ahead of industry trends and regulatory changes. This commitment to improvement allows companies to maintain their competitive edge and ensure that their operations run smoothly.

Load planning is not a one-time effort but an ongoing process that requires attention and adaptation. By prioritizing continuous improvement, businesses can optimize their logistics processes and provide excellent service to their customers.

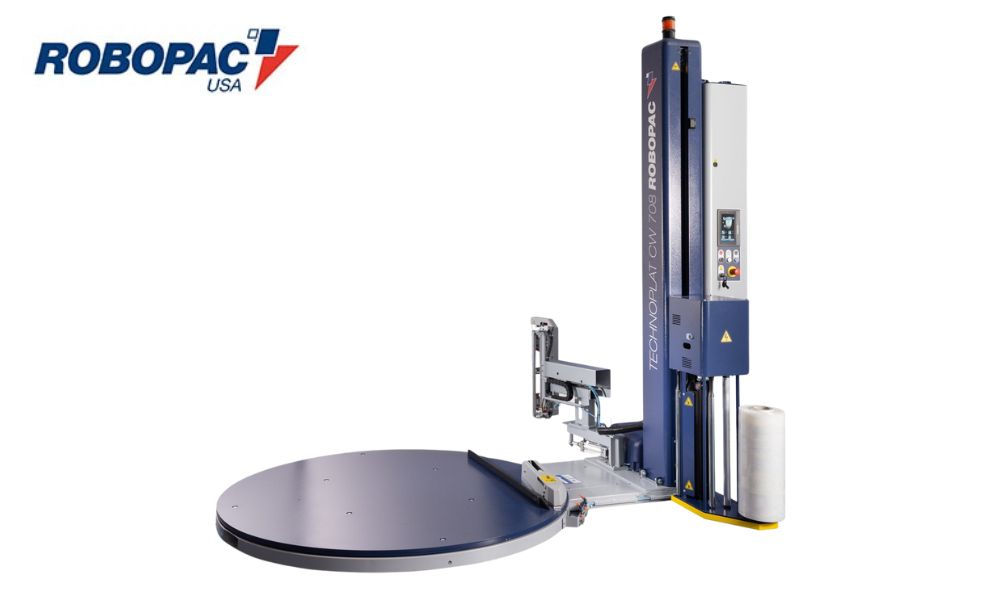

Streamline Workflows With Robopac USA

Creating a successful secondary packaging workflow means investing in the right solutions for every step of the process. Robopac USA can help with our advanced automatic and semi-automatic packaging equipment. Partner with our team today to see how our range of turntable stretch wrappers and other secondary packaging solutions can help streamline your packaging line.