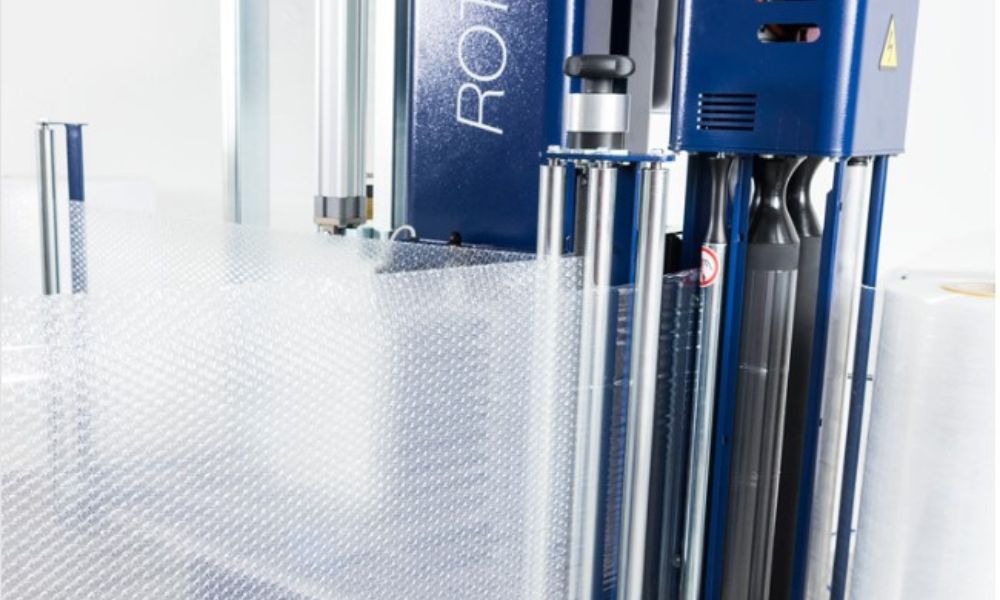

A flexible packaging line can handle a wide range of challenges, allowing you to work with products from across many different industries. However, when you start working with dangerous materials and products, there are a few special considerations you need to make.

Dangerous goods, such as flammable products, corrosive or toxic materials, radioactive or biohazardous goods, explosives, and more, require extreme care to handle and transport them safely. Make sure your packaging line is equipped to address these challenges with this list of things to consider when packaging dangerous goods.

Tailor Your Packaging to the Product

There is not one set way to package hazardous goods. The right technique depends on the type of material or product you’re handling. For example, stretch wrapping is great for heavy, sharp, or awkward objects, but it might not be ideal for some hazardous materials.

Make sure you’re checking Department of Transportation (DOT) regulations and other industry or government requirements to develop and maintain safe, compliant practices regarding packaging equipment, materials, PPE, and other critical factors.

Label Everything Properly

Many hazardous goods require specific labels, instructions, and certified packaging to be shipped legally. These include products and materials such as:

- Aerosols

- Gasoline

- Acids

- Explosives

- Insecticides

- Dry ice

- Radioactive materials

- Lithium batteries

Using the right labels helps you stay compliant and avoid fines when packaging and shipping these kinds of materials. Proper labeling also instructs workers throughout the supply chain on best practices for shipping and handling these goods.

You might also need a special declaration form to ship with the dangerous goods. This form will include details about the product’s classification, quantities, packaging, and any relevant emergency contact information.

Consider Shipping Environments

Another crucial consideration to make when packaging dangerous goods is the kind of environments the products will be exposed to throughout the supply chain. This helps guide your packaging designs and decisions to ensure the goods stay safe and your packaging continues to offer adequate protection across different shipping and transportation environments.

Factors like high humidity or extreme temperature fluctuations can alter the efficacy of your packaging. It’s also important to take special care with materials and products that might become dangerous in certain conditions, such as gases or liquids that react under compression or significant temperature changes. Factoring these considerations into your packaging solution helps you create stable and durable designs that protect the goods throughout the supply chain.

Robopac USA can help you implement flexible stretch wrapping solutions tailored to the needs of your business. Explore our pallet wrapping turntables and other stretch wrapping options when you visit us or talk to our team today.