Packaging fragile products is a challenge across industries, whether you’re shipping food and beverages or personal care and metalworking. Innovative packaging solutions are essential to prevent damage, maintain product integrity, and improve efficiency.

Businesses must balance customer expectations, cost reduction, and supply chain complexities. In this blog, we’ll examine innovations in fragile product packaging that allow companies to transport delicate items with peace of mind.

Types of Fragile Products and Their Unique Challenges

Certain industries must take extra precautions when packaging items due to the fragile nature of their products. Each sector has its own specific packaging requirements to protect against damage during storage, handling, and shipping.

Food and Beverage

From eggs and glass beverage bottles to soft fruits and other perishables, the food and beverage industry requires packaging that ensures both physical protection and product freshness. To achieve both requirements, packaging professionals must navigate unique structural and temperature-related challenges.

Personal Care Products

Items such as glass perfume bottles, high-end cosmetics, and skincare products need durable yet aesthetically pleasing packaging to reinforce brand value while safeguarding the contents. Companies must package items carefully to avoid common risks with these products, like spills, cracks, and contamination.

Metalwork

This lesser-discussed sector also faces packaging dilemmas. Products like tool inserts, custom metal components, and precision-engineered materials are prone to nicks and damage without secure casing. Packaging strategies like durable wraps and compartmentalized solutions keep products safe during shipping or on shop floors.

Key Packaging Innovations

Many packaging innovations for fragile products exist to overcome the common challenges of these industries and others. From case packer machines to pad and film packaging, many methods are available to safely and securely transport delicate items.

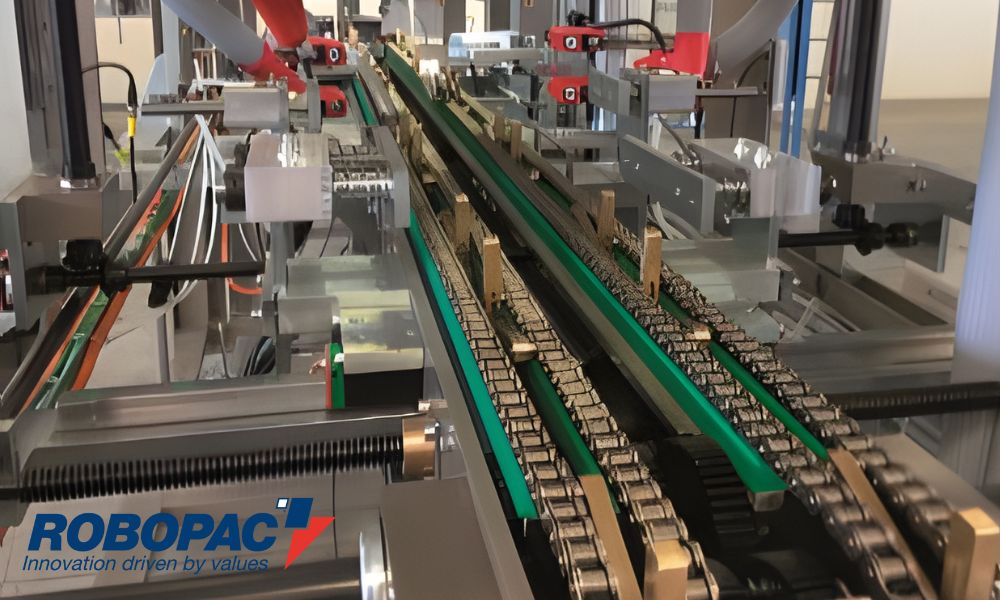

Industrial Case Packer Machines

Industrial case packer machines represent the pinnacle of secure and efficient packaging. Case packer equipment operates with precision, efficiently placing fragile items into cases while reducing breakage. Their ability to handle a high number of cycles per minute (CPM) makes them ideal for high-volume operations, saving time and labor costs.

Wrap-Around Case Packers

For businesses handling irregular or oddly shaped items, wrap-around case packers are a handy solution. This equipment creates tailor-fit wraps, ensuring products stay in place during transit. The versatility of these machines allows companies to process multiple product formats without the hassle of constant retooling.

Film Packaging

Film packaging provides a lightweight yet durable option that clings tightly to fragile goods. Shrink and stretch film applies an even, protective layer that prevents products from shifting or colliding. Given the advancements in biodegradable and eco-friendly films, this option also aligns with sustainability goals.

Pad and Film Packaging

Combining the protective cushioning of pads with the coverage of films creates incredibly stable packaging. The added layer securely holds items in position while reducing the risk of damage from rough handling or environmental factors. This approach is particularly effective in the food, beverage, and cosmetics sectors.

Secure Fragile Product Packaging With Robopac USA

Innovative packaging goes beyond protecting products—it enhances customer satisfaction by ensuring items arrive intact and ready to use. If you require packaging equipment to protect breakable objects, Robopac USA can help. Explore our packaging solutions today to revolutionize your process.