LT AUTOMATIC

Entry-Level Automation. High-Level Performance.

The LT Automatic is a compact, American-made stretch wrapping solution designed to bring reliable automation to low-to-medium volume operations. With a fast 17 RPM turntable and a footprint that fits almost anywhere, it helps you wrap pallets quicker, safer, and with less film—boosting productivity without overcomplicating your workflow.

Why Choose the LT Automatic?

-

Fast & Efficient – Wrap at up to 17 RPM with consistent, secure results

-

Compact Footprint – Fits into tight spaces without sacrificing performance

-

Safe by Design – Automatic operation with full safety fencing to protect your team

-

Cost-Effective – Reduce film usage and labor without the price tag of a high-volume system

Key Features

-

10” Color Touchscreen – Intuitive control with real-time system feedback

-

Allen Bradley PLC & Drives – Trusted reliability and precision performance

-

15 Custom Wrap Recipes – Powered by Cube Technology™ for smart film application

-

Variable Turntable & Carriage Speeds – Fine-tune wrap cycles to match your product

-

Automatic Load Height Sensing – Ensures complete coverage every time

-

Automatic Film Tail Treatment – Clamp, cut, and wipe for a clean finish

-

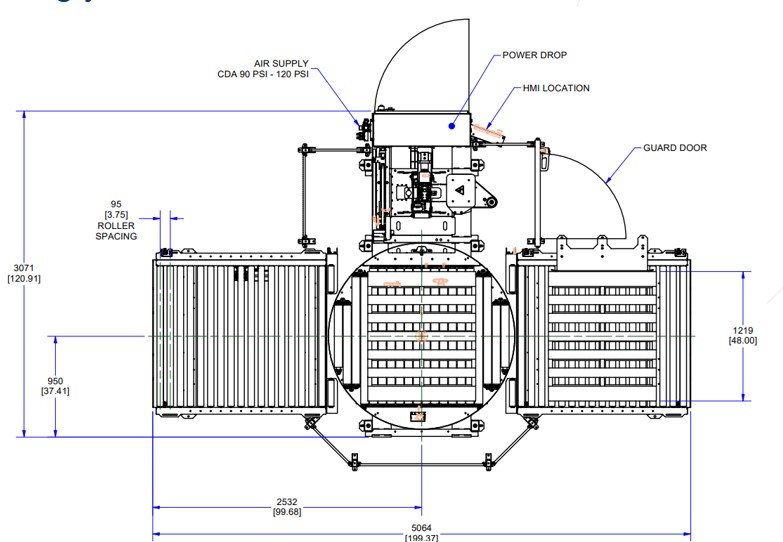

5′ Infeed & Outfeed Conveyors – Streamlined flow of pallets through your line

-

Adjustable Conveyor Pass Heights – 18” to 24” for flexible integration

-

Safety Fencing – Keeps operators protected during operation

CONTROL PANEL

Includes Allen Bradley Micro 800 series PLC. The 10 inch control panel with color touch screen makes it easy to program and operate. Includes 15 customizable wrap recipes with Cube Technology.

AUTOMATIC LOAD HEIGHT SENSING AND FILM TAIL TREATMENT

Automatically senses top of load to provide your load with full film coverage. Cut, clamp, and wipe down unit secures the film tail at the end of the wrap cycle to the load to avoid loss of containment at the bottom of the load.

SMALL FOOTPRINT

With one of the smallest footprints in its category, the LT Automatic is able to be placed in areas that meet your operations workflow requirements.

SAFETY

The machinery includes industry standard safety fencing and photo eyes. The customer is in the best position to determine whether additional safety devices are necessary for your application. In addition, Robopac does offer and encourages the use of category three safety devices, which are available to be added as options to the machine. If you believe the industry standard fencing and photo eyes do not provide adequate protection for your unique application, you should purchase the category 3 devices. These important safety issues are the sole responsibility of the customer.