Artificial intelligence (AI) is helping businesses raise the bar in packaging by making processes faster, safer, and more reliable. Tasks like precision wrapping and efficient sorting are now smoother thanks to AI-powered automation. Machine learning (ML) is a type of AI that focuses on enabling systems to learn and improve from data without being explicitly programmed. See how machine learning is shaping the future of palletizing, helping businesses save time and money.

What Is Machine Learning in Palletizing?

Machine learning refers to the use of smart algorithms that help systems make better decisions by learning from data. Older automated methods depend on rigid programming and fixed rules. In contrast, machine learning technology can easily adjust to products of varying shapes, sizes, and weights, ensuring a more effective and reliable palletizing process.

The standout feature of machine learning is its ability to learn and improve from data. By analyzing information from past stacking patterns, warehouse layouts, and packaging needs, these systems become more efficient over time. This helps businesses tackle common challenges in palletizing, like space utilization and load stability, to save time and cut costs.

Adapting in Real Time

Machine learning palletizing systems stand out because they can adapt to problems in real time. Automatic adjustments help businesses avoid downtime, reduce errors, and maintain efficient operations. Real-time adjustments provide a level of flexibility that traditional systems simply can’t match, paving the way for more resilient supply chain operations.

Here are some examples of issues these systems can respond to:

- If boxes are misaligned, the system adjusts the stacking pattern to maintain stability.

- When a product is damaged, the system skips the item and recalculates the arrangement.

- If there is a change in product size, the system recalibrates to stack varying dimensions effectively.

- When items are missing, the system updates the stacking plan to fill gaps seamlessly.

- If there are sudden shifts in product demand, the system adjusts its speed to match the pace.

Enhancing Load Stability

Load stability refers to how well a palletized load stays secure and balanced during storage or transport. A stable load is crucial for preventing accidents, product damage, or wasted space in warehouses and trucks.

However, achieving stability can be difficult because products often come in different shapes, sizes, and materials. Traditional palletizing methods rely on fixed patterns that may not account for these differences, leading to weak or unstable stacks.

Machine learning palletizing systems analyze product data, such as weight distribution, material type, and shape, to determine the best stacking strategy. For instance, they can identify the heaviest items and place them at the base for a stronger foundation. ML-powered palletizers also change the stacking pattern if they detect issues like gaps or tilting as the pallet is being built. By constantly optimizing the process, these systems confirm that every load is stable and safe, even with varied or unpredictable products.

Customizing Palletizing for Products

Machine learning is shaping the future of packaging by simplifying customized palletization. Fragile items like glass bottles require careful handling and precise placement to prevent damage. The system uses details like weight, material, and shape to create the safest arrangement. Irregularly shaped items, such as odd-sized packages, fit securely with calculated adjustments.

ML-driven palletizers can arrange temperature-sensitive products that expand or shrink in a way that reduces pressure. They also position unevenly weighted items, like partially filled liquid containers, to maintain balance. By customizing the palletizing process for specific needs, machine learning ensures stacks are safe to transport.

Boosting Productivity With Automation

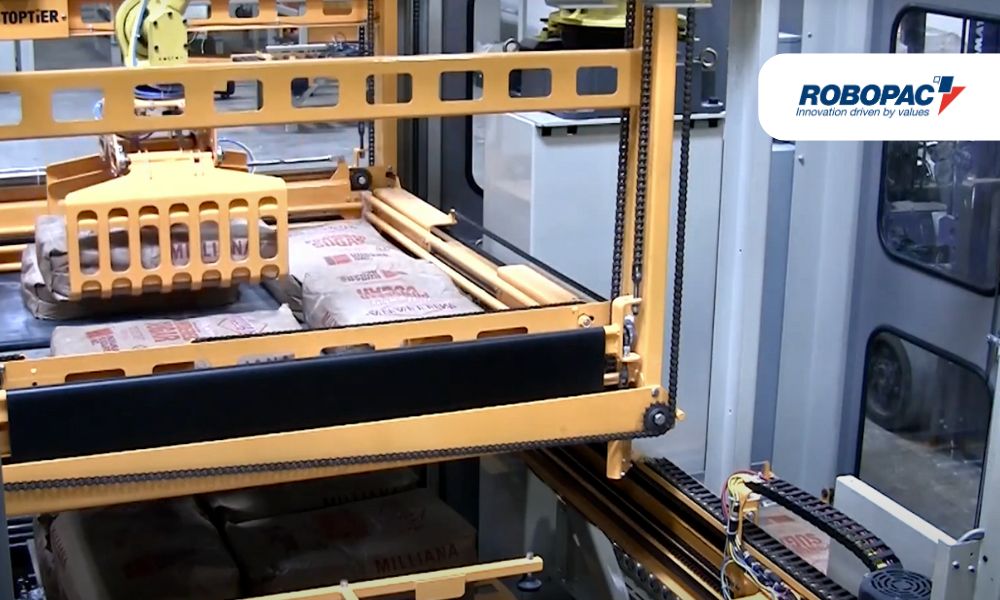

Automation is an inherent benefit of using machine learning in palletizing. By minimizing the need for manual work, Robopac USA’s palletizing equipment enables companies to process more pallets in less time. Robots equipped with machine learning software can work around the clock, providing consistent output and high efficiency.

Automation also boosts productivity by reducing human errors. Mistakes in pallet stacking, like uneven loads or improper placement, can lead to damaged goods or safety risks. Automated machine-learning systems prevent these issues, so businesses don’t have to spend extra time and resources on rework, repairs, and product replacements.

Learning for Better Stacking

Machine learning systems continuously improve through data. With every pallet they stack, these systems learn, analyze, and apply insights to future operations. This constant refinement leads to more accurate and efficient palletizing over time.

By leveraging historical data, machine learning systems identify patterns that might not be visible to human operators. This learning capability ensures businesses stay ahead of trends and optimize their supply chains.

Machine learning systems can evaluate data on the following factors to identify opportunities for improvement:

- Stacking patterns

- Weight distribution

- Packaging material usage

- Load stability

- Space utilization

- Product-specific adjustments

Using the Right Amount of Materials

Machine learning palletizing reduces costs by making sure materials are used as efficiently as possible. These systems calculate the exact amount of wrapping, padding, or other packaging materials required for each pallet, avoiding overuse. This precision not only lowers expenses on supplies but also adds to overall operational efficiency.

Another way machine learning improves material efficiency is by reducing errors that lead to unnecessary waste. When pallets are balanced and stable, there’s less risk of needing to repack items or replace damaged goods, which often requires additional materials.

Machine learning systems also help optimize the spacing between items, making sure the entire pallet surface is utilized. Using the full pallet surface reduces the need for excess wrapping or padding to secure items. It also helps businesses transport more products in fewer trips and reduces shipping costs.

The Future of AI Palletizing

The future of palletizing lies in the continued evolution of AI and machine learning. For example, innovations in robotic vision help machines “see” and understand the physical world with cameras and sensors. This technology enables robots to identify and handle different products with minimal errors. Combined with machine learning, robotic vision ensures that pallets are stacked safely and efficiently every single time.

As machine learning technology becomes more accessible, even small businesses will be able to harness its potential. Widespread adoption will result in more efficient, safe, and sustainable palletizing.

The integration of machine learning into palletizing is revolutionizing how businesses handle packaging and shipping. By analyzing past data and adapting in real time, these systems improve efficiency, prevent errors, and ensure load stability during transport. Customized palletizing makes operations safer and better suited to unique challenges.