ROTOPLAT 3000 HD

Rugged. Compact. Built for High Capacity.

The Rotoplat 3000 HD is a heavy-duty automatic turntable stretch wrapper engineered for operations that need reliable, high-volume wrapping in a compact footprint. Whether you’re scaling up or replacing aging equipment, this machine delivers performance that lasts.

Built to Perform

Designed for demanding environments, the Rotoplat 3000 HD combines industrial durability with smart automation—helping you wrap more pallets, more efficiently, with less downtime.

Optional Features for Customization

Tailor the machine to your exact needs with these available upgrades:

-

30” Film Carriage – Wrap larger loads with fewer revolutions

-

Roping – Improve load containment for unstable or heavy products

-

Top Cover Placement – Protect loads from dust and moisture

-

Top Pressure Hold Down – Secure tall or lightweight pallets during wrapping

-

R-Connect® – Monitor performance and troubleshoot remotely

Why Choose the Rotoplat 3000 HD?

-

Compact footprint with high-capacity output

-

Flexible configuration to match your workflow

-

Durable build for industrial reliability

-

Automation-ready with smart connectivity

PRE-STRETCH CARRIAGES

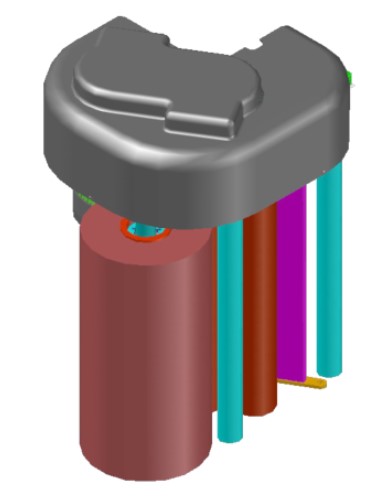

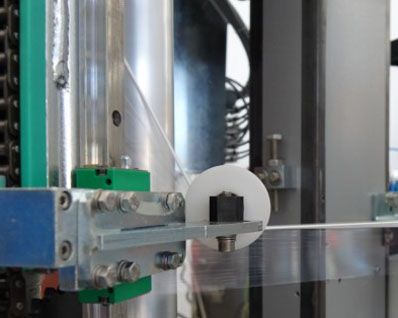

PGSM CARRIAGE

This system uses a single motor to pre-stretch film up to 340%, with up to 12 selectable force levels for film application on the pallet. Force containment is controlled via an analog adjustment system. The carriage is compatible with a standard 20" film reel (h - 20”) and can be optionally configured for a 30" reel (h - 30”). Additional pre-stretch kits beyond the standard configuration are also available.

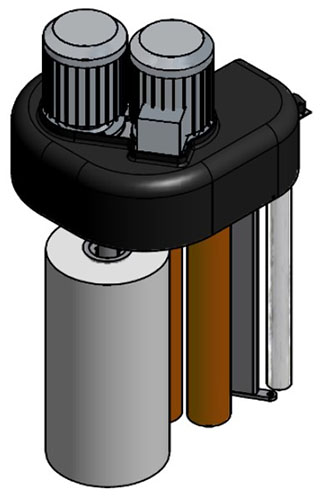

PGSA CARRIAGE

Equipped with two independent motors, this carriage allows film pre-stretch adjustment directly from the control panel, offering a stretch range from 150% to 400%. The system is managed via an inverter for precise control. Up to 12 force containment levels can be applied to the pallet. Containment force is regulated by a reactive system powered by CUBE TECHNOLOGY Level 1. The carriage supports a standard 20" reel (h - 20") and is optionally available with a 30" reel (h - 30”).

CLAMPS

PINCERS CLAMP

The standard clamp includes a hot wire system for reliable film cutting. An optional version with dual actuators is available, allowing independent movement of the two pincers—ideal for wrapping pallets of varying sizes.

HOT PLATE SEALER

This device secures the final edge of the film to the previous wrap during the wrapping cycle. Film is cut using a hot wire, while spring-mounted sealing plates adapt to the product's surface for consistent contact. Sealing time is adjustable via the control panel for optimal performance.

SPRING CLAMP

Optional system for clamping, cutting and sealing the film, which occurs without contact with the product. The device works through spring steel (Patented), with a proportional reduction of the film band and is complete with an air blower device to seal the initial edge of the film within the wrapping. The device is specifically designed to guarantee perfect finishing of the end edge of the film by electronically controlled impulse sealing on constant film thickness. The final sealing of the film takes place on a mechanical support, accurately avoiding direct contact with the product.

MAIN OPTIONS

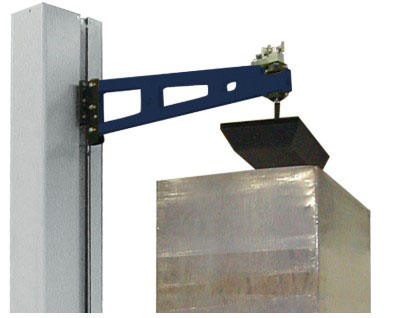

VERTICAL PRESSURE PLATEN

Pallet retaining system during wrapping which can be used with the upper covering systems (Top Inside/Top Outside) or with particularly unstable loads. Available in versions with mechanical or pneumatic drive.

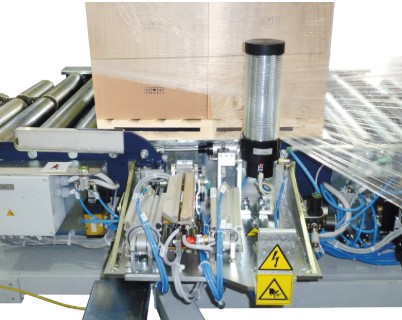

TOP SHEET INSERTER

Automatic system for covering the upper surface of the pallet. Film preparation and cutting occur during the wrapping cycle, minimizing machine downtime for positioning the sheet; the production capacity is virtually unchanged. Independent support structure, therefore it can be easily installed on existing wrapping lines.

ROPING DEVICE

Optional system to reduce the width of the film to a "cord" and ensure a more effective stabilization of the load.

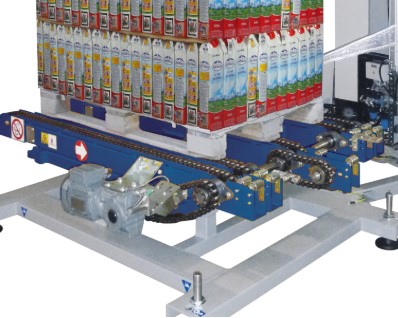

TABLE WITH CHAINS

The table with chain conveyor is available for loads with bottom slat pallets transversal to the feed front. Table with chain conveyor with 3, 4 or 5 ways available.

| Performance | |

| Production Speed | 44 LPH |

| Rotation Speed | 17 RPM |

| Load Capacity | |

| Max Load Dimensions (W X L) | 40" X 48" |

| Min Load Dimensions (W X L) | Min Load Dimensions (W X L) |

| Load Height | 20" - 80" |

| Machine Structure | |

| Frame Construction | Formed Steel |

| Film Delivery System | |

| Pre-Stretch | Multi Level Variable 0-400% |

| Containment Force | Multi-Level Variable |

| Standard Film Width | 20" or 30" |

| Height Sensing | Photocell |

| Film Threading | Patented S-Pattern |

| Corner Compensation | Cube 1 |

| Film Thickness | 47 - 120 |

| Operator Interface | |

| Control Panel | Allen Bradley Panel View Plus 600 |

| Wrapping Menus | 12+ Programmable Menus |

| Utility Requirements | |

| Electrical | 480V 60Hz |

| Air Pressure | 87 PSI |

| Safety Features | |

| Emergency-Stop Push Button | YES |

| UL 508A Compliant | YES |

| Safety Guard Door & Switch | YES |

| Warranty | 3 Years |

| 30" Film Carriage |

| Ramp |

| Scale Package |

| Extended Warranty |