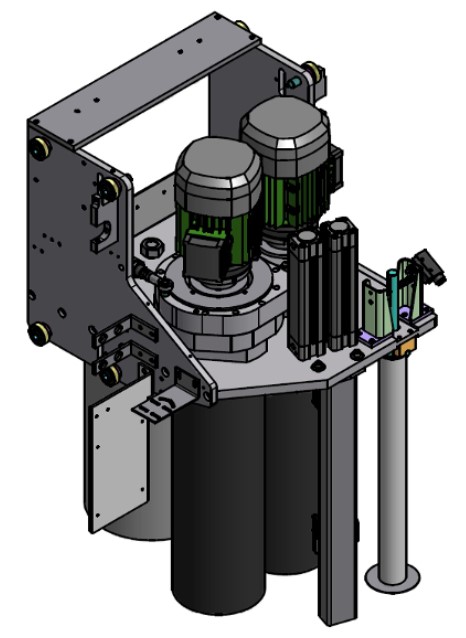

Helix 4/2 – Dual-Carriage Rotary Arm Stretch Wrapper

Maximum Throughput. Unmatched Efficiency.

The Helix 4/2 is Robopac’s most advanced automatic rotary arm stretch wrapper—engineered for ultra-high-speed applications where maximum productivity and uptime are non-negotiable. With twin film carriage technology and a 36 RPM rotary arm, the Helix 4/2 can wrap up to 145 pallet loads per hour, making it the top choice for demanding, high-throughput operations.

Key Features:

-

Twin Film Carriage System – Doubles wrapping speed and reduces cycle time

-

36 RPM Arm Speed

-

Wraps up to 145 loads/hour

-

Rotary Arm Design – Ideal for unstable or lightweight pallet loads

-

Modular Options Include:

-

30” Film Carriage

-

Film Roping

-

Top Cover Placement

-

Top Pressure Hold Down

-

Pallet Lifter

-

Auto Corner Board Placement

-

R-Connect® for smart monitoring and diagnostics

-

Why Choose the Helix 4/2?

-

Industry-Leading Throughput: Designed for 24/7, high-volume operations

-

Reduced Downtime: Twin carriages cut wrapping time and increase efficiency

-

Lower TCO: Built for long-term reliability with low maintenance requirements

-

Future-Ready: Fully customizable and integration-ready for automated lines

For operations that can’t afford to slow down, the Helix 4/2 delivers unmatched performance, flexibility, and durability.

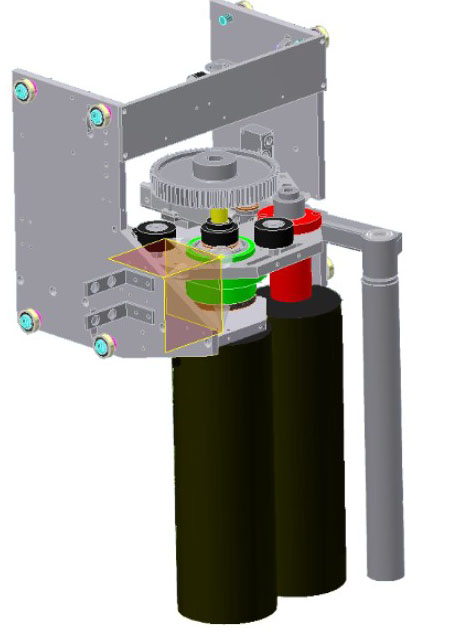

PRE-STRETCH CARRIAGES

SCSP CARRIAGE

Pre-stretch carriage with single motorization, which allows the stretch film to be pulled at fixed values up to 300% and apply up to 12 containment force values on the pallet. Optional kits are available for pre-stretch other than standard. The adjustment of the placing force on the pallet is controlled by an analog system.

The carriage is equipped with a reel h. 20″ (STD) or with the optional h. 30”.

SCSP/2 CARRIAGE

Pre-stretch carriage with double motorization SSC independent, which allows the stretch film to be pre-stretched from the control panel, with a 150% -400% range and with control system through inverter. It is possible to apply up to 12 containment force values on the pallet. The carriage is equipped with a reel h. 20″ (STD) or with the optional h. 30”. Available carriage for reel h. 20 inch version Jumbo with diameter 15 inches. The adjustment of the application force on the pallet is controlled by a PROACTIVE system based on the CUBE TECHNOLOGY Level 1 and Level 2

CLAMPS

EVO PINCERS CLAMP

Standard clamp equipped with a system for cutting the film through a hot wire. Also available in the version with double driver for independent movement of the two pincers, ideal for pallets of varying size.

HOT PLATE SEALER

Hot plate device to fix the final edge of the film during wrapping cycle on the previous turn. The film is cut by means of the hot wire. The sealing plates are mounted on springs to adapt to the surface of the product, and the sealing time can be set from the control panel.

EVO SPRING CLAMP

Optional system for clamping, cutting and sealing the film, which occurs without contact with the product. The device works through spring steel (Patent), with a proportional reduction of the film band and is complete with an air blower device to seal the initial edge of the film within the wrapping. The device is specifically designed to guarantee perfect finishing of the end edge of the film by electronically controlled impulse sealing on constant film thickness. The final sealing of the film takes place on a mechanical support, accurately avoiding direct contact with the product. Also available in the version with horizontal movement, mobile and liftable.

NIP AND TUCK CLAMP

Optional device for clamping, cutting and threading the film without sealer. The last tail of the wrapping film is inserted into the winding itself.

MAIN OPTIONS

VERTICAL PRESSURE PLATEN

Pallet retaining system during wrapping which can be used with the upper covering systems (Top Inside/Top Outside) or with particularly unstable loads. Available in versions with mechanical movement by means of pantograph system or pneumatic drive.

PALLET LIFTER

Pallet lifting system in the conveyor in the center of the machine with pneumatic drive or hydraulic drive, thanks to which complete wrapping of the wooden pallet is possible. This system enables you to manage wrapping of the product and pallet in an extremely flexible manner, guaranteeing maximum stability of the palletized load. The pneumatic lift has a maximum capacity of 4400 lbs., while the hydraulic system has a capacity of more than 4400 lbs.

TOP COVER

Automatic system for covering the upper surface of the pallet. Available in the version Top Inside version integrated in the structure of the machine to obtain a cover against dust and water, or in the Top Outside version with independent structure, to be able to achieve a dust-proof cover.

ROPING DEVICE

Optional system to reduce the width of the film to a “cord” and ensure a more effective stabilization of the load.

VCA CORNER APPLICATOR

Thanks to a special control system (patented ROBOPAC), the gripping and application devices are able to “locate” in a fully automatic way the four corners of the pallet without any manual setting or adjustment of the system.

| Performance | |

| Loads/HR | 145 |

| RPM | 36 |

| Load Capacity | |

| Max Load Dimensions (W X L X H) | 40 x 53 |

| Machine Structure | |

| Frame Construction | Painted Metal |

| Film Delivery System |

| Operator Interface | |

| Wrapping Menus | 16 |

| Utility Requirements | |

| Electrical | RITTAL CABINET |

| Pneumatics | FESTO |

| Safety Features | |

| CE Safety-Cat 3 | YES |

| UL 508A Compliant | YES |

| 30" Film Carriage |

| Air Conditioning |

| Scale Package |

| Self Centering Devices |