Genesis Thunder – High-Speed Rotary Ring Stretch Wrapper

Maximum Speed. Minimal Maintenance. Superior Flexibility.

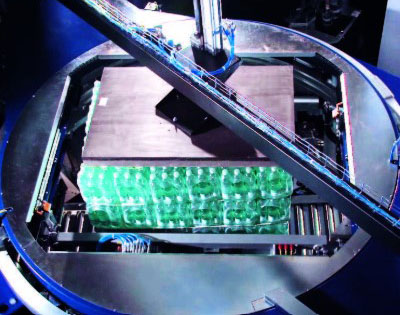

The Genesis Thunder is Robopac’s most advanced rotary ring automatic stretch wrapper, engineered for high-speed pallet wrapping with unmatched reliability and efficiency. With a blazing-fast 65 RPM ring speed, it can wrap up to 120 loads per hour—making it ideal for the most demanding production environments.

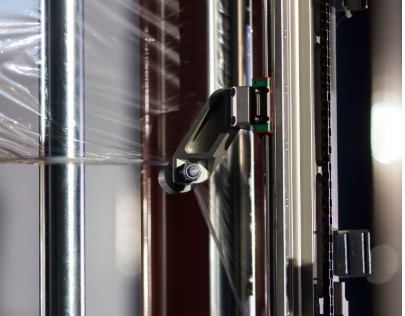

Built with a hi-resistance monoblock aluminum ring and servo-controlled direct-drive pre-stretch motors, the Genesis Thunder ensures precise film application, energy efficiency, and low maintenance requirements.

Key Features:

-

65 RPM wrapping speed – up to 120 pallet loads/hour

-

Monoblock aluminum ring for strength and durability

-

Servo-controlled direct-drive pre-stretch motors for precise film control

-

Hygienic and ergonomic design – ideal for food and cleanroom environments

-

Extremely quiet operation

-

Automatic dynamic parachute system for enhanced safety

-

Compatible with all pallet sizes

-

Engineered for low maintenance and minimal interventions

Whether you’re looking to maximize throughput, improve uptime, or handle a wide range of pallet sizes, the Genesis Thunder delivers industry-leading performance with the lowest total cost of ownership in its class.

R-Connect®, available for this machine is our latest innovation was developed to provide usage and performance data via the cloud, enabling you to meet Industry 4.0 demands by putting performance monitoring & optimization at your fingertips. Utilization drastically reduces downtime by giving you informational transparency, allowing you to connect with your machines remotely to investigate alarms, adjust parameters, & respond promptly. This Industry 4.0 innovation empowers you with actionable insight to continuously improve performance, cost savings, & automation.

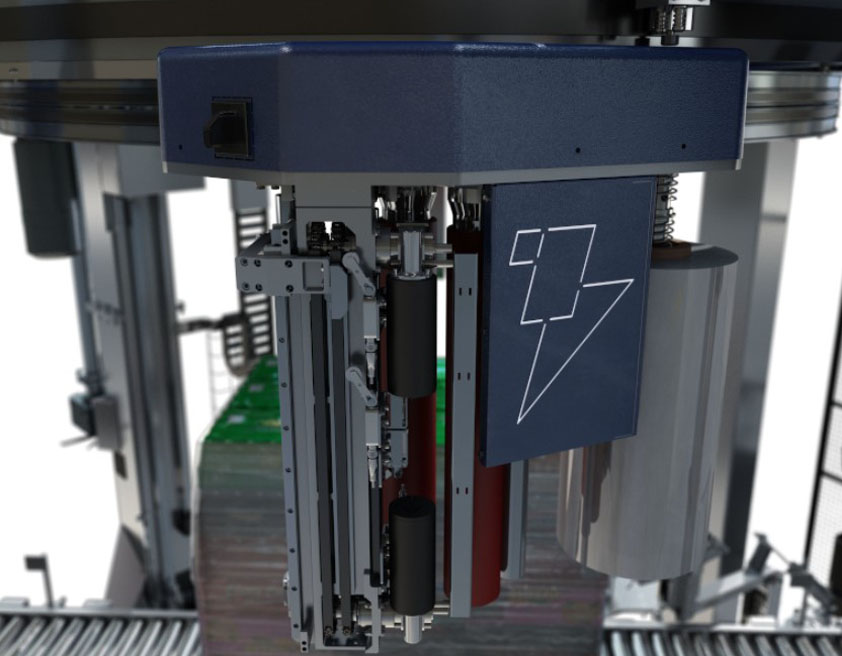

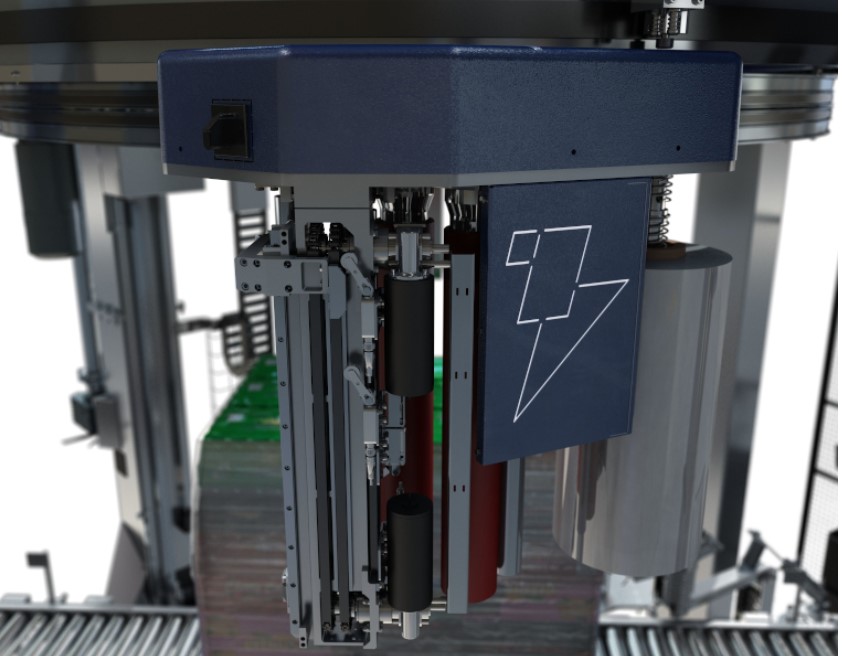

PRE-STRETCH CARRIAGES

BGS CARRIAGE

Servo controlled single motor pre-stretch carriage with external direct-drive motorization. The carriage works without sliding contacts, eliminating all failures caused by this technology, ensuring greater safety levels and the possibility of use in all environments. Possibility to pre-stretch the film at fixed values (optional kits are available for pre-stretch other than standard) and apply up to 12 containment force values on the load. Force to load is controlled by a REACTIVE analogic system in the EASY TECH version, instead is PROACTIVE in the EASY TECH+ version.

BVS CARRIAGE

Servo controlled two motors pre-stretch carriage with external direct-drive motorization. The carriage works without sliding contacts, eliminating all failures caused by this technology, ensuring greater safety levels and the possibility of use in all environments. Possibility to pre-stretch the film in variable way, in continuous and adjustable on HMI and apply up to 12 containment force values on the load. Force to load is controlled by a PROACTIVE system based on the CUBE TECHNOLOGY Level 1 and Level 2

CLAMPS

FUTURA CLAMP

Pneumatically driven clamp unit with hot wire film cutting which incorporates also the device for final sealing of the film tail on the contrast.

NIP AND TUCK CLAMP

Optional device for clamping, cutting and threading the film without sealer. The last tail of the wrapping film is inserted into the winding itself.

MAIN OPTIONS

VERTICAL PRESSURE PLATEN

The device can be used with particularly unstable loads.

PALLET LIFTER

Pallet lifting system located under the conveyor in the machine center.

TOP COVER

Device for covering the upper side of the pallet.

ROPING DEVICE

Optional system to reduce the width of the film to a “cord” and ensure a more effective stabilization of the load.

VCA CORNER APPLICATOR

Thanks to a special control system (patented ROBOPAC), the gripping and application devices are able to “locate” in a fully automatic way the four corners of the pallet without any manual setting or adjustment of the system.

ARC REEL CHANGE

| Performance | |

| Loads/HR | 120 |

| RPM | 65 |

| Load Capacity | |

| Max Load Dimensions (W X L) | 44 x 52 |

| Min Load Dimensions (W X L) | Min Load Dimensions (W X L) |

| Machine Structure | |

| Frame Construction | Painted Metal |

| Film Delivery System | |

| BGS Carriage | Servo controlled single motor pre-stretch carriage with external direct-drive motorization. The carriage, works without sliding contacts, eliminating all failures caused by this technology, ensuring greater safety levels and the possibility of use in all environments. Possibility to pre-stretch the film at fixed values (optional kits are available for pre-stretch other than standard) and apply up to 12 containment force values on the load. Force to load is controlled by a REACTIVE analogic system in the EASY TECH version, instead is PROACTIVE in the EASY TECH+ version. |

| BVS Carriage | Servo controlled two motors pre-stretch carriage with external direct-drive motorization. The carriage works without sliding contacts, eliminating all failures caused by this technology, ensuring greater safety levels and the possibility of use in all environments. Possibility to pre-stretch the film in variable way, in continuous and adjustable on HMI and apply up to 12 containment force values on the load. Force to load is controlled by a PROACTIVE system based on the CUBE TECHNOLOGY Level 1 and Level 2 |

| Operator Interface | |

| Wrapping Menus | 16 |

| Utility Requirements | |

| Standard power supply voltage and frequency | 400-415 ± 5% - 50 Hz |

| Safety Features | |

| CE Safety-Cat 3 | YES |

| UL 508A Compliant | YES |

| 30" Film Carriage |