Genesis Futura 40 – Rotary Ring Automatic Stretch Wrapper

High-Speed Performance. Low Maintenance Design.

The Genesis Futura 40 is a rugged, high-capacity automatic rotary ring stretch wrapper engineered to meet the demands of high-throughput operations. With a 40 RPM ring speed and the ability to wrap up to 80 pallet loads per hour, this system delivers powerful performance with smart design advantages.

What sets it apart is Robopac’s patented power delivery system for the pre-stretch carriage—eliminating the need for sliding electrical contacts. This innovation significantly reduces wear, minimizes maintenance, and helps avoid costly downtime.

Key Features:

-

Rotary ring design for smooth, high-speed operation

-

Wraps up to 80 loads/hour

-

40 RPM wrapping speed

-

Patented no-contact power system for reduced maintenance

-

Ideal for high-volume, continuous operations

The Genesis Futura 40 combines performance, efficiency, and reliability—making it a smart investment for busy packaging lines.

PRE-STRETCH CARRIAGES

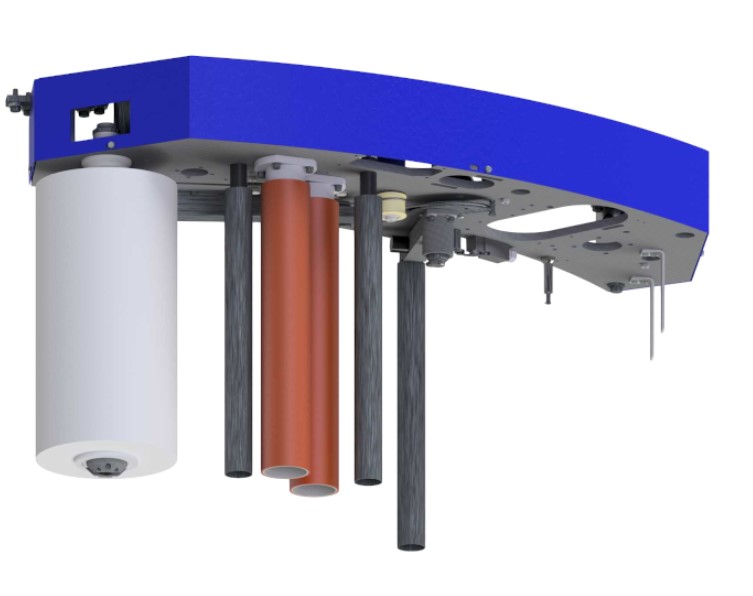

BSCSP CARRIAGE

The Genesis Futura 40 features a carriage with single motorization on-board and automatically recharged batteries to obtain film pre-stretching since the beginning of the wrapping process.

Possibility to pre-stretch the stretch film at fixed values up to 300%. Optional kits are available for pre-stretch other than standard. The adjustment of the containment force on the pallet is reactive and controlled by an analog system.

USCSP/2 CARRIAGE

Pre-stretch carriage with double independent DC motorization on-board, with electric current generator and ultra-capacitors. It stands out due to the absence of sliding contacts, therefore suitable to all work environments.

CLAMPS

FUTURA CLAMP

Pneumatically driven clamp unit with hot wire film cutting which incorporates also the device for final sealing of the film tail on the contrast.

NIP AND TUCK CLAMP

Optional device for clamping, cutting and threading the film without sealer. The last tail of the wrapping film is inserted into the winding itself.

MAIN OPTIONS

VERTICAL PRESSURE PLATEN

Pallet retainer system during wrapping, mandatory with upper covering systems (Top Inside / Top Outside) or with particularly unstable loads.

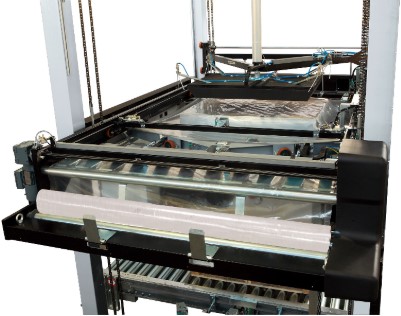

TOP COVER

Automatic system for covering the upper surface of the pallet. Available in the version Top Inside version integrated in the structure of the machine to obtain a cover against dust and water, or in the Top Outside version with independent structure, to be able to achieve a dust-proof cover.

PALLET LIFTER

Pallet lifting system in the conveyor in the center of the machine with pneumatic drive or hydraulic drive, thanks to which complete wrapping of the wooden pallet is possible. This system enables you to manage wrapping of the product and pallet in an extremely flexible manner, guaranteeing maximum stability of the palletized load. The pneumatic lift has a maximum capacity of 4400 lbs., while the hydraulic system has a capacity of more than 4400 lbs.

ROPING DEVICE

Optional system to reduce the width of the film to a “cord” and ensure a more effective stabilization of the load.

VCA CORNER APPLICATOR

Thanks to a special control system (patented ROBOPAC), the gripping and application devices are able to “locate” in a fully automatic way the four corners of the pallet without any manual setting or adjustment of the system.

ARC REEL CHANGE

| Performance | |

| Loads/HR | 80 |

| RPM | 40 |

| Load Capacity | |

| Max Load Dimensions (W X L) | 44 x 52 |

| Min Load Dimensions (W X L) | Min Load Dimensions (W X L) |

| Machine Structure | |

| Frame Construction | Painted Metal |

| Film Delivery System |

| Operator Interface | |

| Wrapping Menus | 16 |

| Utility Requirements | |

| Safety Features | |

| CE Safety-Cat 3 | YES |

| UL 508A Compliant | YES |

| 30" Film Carriage |

| Air Conditioning |