Packaging is more than just a protective shell for products; it’s the first tangible interaction customers have with your brand. When implemented correctly, packaging can elevate the perceived value of your products, streamline your supply chain, and enhance customer satisfaction.

However, even small packaging errors can undermine your efforts and result in added costs, dissatisfied customers, and damage to your brand’s reputation. Understanding the common pitfalls is the first step in refining your packaging operations and minimizing costly mistakes. Learn more about the most common packaging errors and how you can avoid them in your business.

Understanding the Impact of Packaging Errors

Packaging errors can have far-reaching effects on a business’s bottom line and reputation. Poor secondary packaging can lead to lost or damaged pallets, which in turn creates increased shipping costs due to returns and reshipments. Damaged products not only incur additional costs but also tarnish a brand’s image, leading to diminished customer trust and loyalty. Similarly, primary packaging mistakes leave a poor impression on customers, damaging brand image and ruining the customer experience.

Additionally, negative customer impressions can spread quickly. Packaging that fails to meet expectations can result in poor reviews and lost sales. To mitigate these impacts, your business must prioritize meticulous attention to packaging details, ensuring that each element reflects the quality and care associated with your brand.

Branding Inconsistencies

Good packaging design gives you the opportunity to show off your brand in a positive light. This means that consistency in packaging design is crucial. Customers recognize brands by their colors, fonts, and overall design elements. When these aspects aren’t consistent across all packaging, it can lead to confusion and dilute your brand identity. This inconsistency can arise from using different shades of a color, varying font styles or sizes, or adopting an inconsistent tone in packaging copy.

To maintain a cohesive brand image, you must establish a clear set of brand guidelines for your business. These guidelines should specify the exact color codes, font types, and logo placements you want to use across all packaging.

Conduct regular audits to ensure compliance with these guidelines. It’s also a good idea to set up feedback loops between design and production teams to minimize errors and encourage ongoing refinement of your designs. By prioritizing precision in packaging design, you can build a strong, recognizable brand that stands out to customers and represents your business well.

Using the Wrong Packaging Materials

Choosing the right packaging materials can be the difference between a product that arrives safely and one that is damaged during transit. It is crucial to tailor your material choices to your specific products and packaging designs. Fragile items require more protective materials like bubble wrap or foam, while perishable goods need packaging that can maintain temperature and freshness.

High-quality packaging materials are essential for safeguarding products and ensuring they arrive intact. Your business should invest in durable, reliable materials that suit the specific needs of your products. Testing different materials under various conditions can help you determine the best option for each product type. By taking the time to select the appropriate packaging materials, you can reduce damage-related costs and enhance customer satisfaction.

Overlooking Sustainable Packaging

In today’s environmentally conscious market, sustainable packaging has become a significant consideration for businesses. Sustainable packaging helps minimize environmental impact by using materials that are recyclable, biodegradable, or made from renewable resources. Businesses that overlook sustainable packaging not only miss out on potential cost savings but also risk alienating eco-conscious consumers.

Investing in sustainable packaging can offer numerous benefits, including reduced waste, a lower carbon footprint, and a positive brand image. Explore options such as recycled materials, minimalistic designs that reduce material use, and clever packaging solutions that consumers can reuse. By aligning your packaging practices with sustainability goals, your business can appeal to a growing segment of environmentally aware consumers while also improving operational efficiency and contributing to a healthier planet.

Leaving Typos, Misprints, and Other Labeling Mistakes

Clear and accurate labeling is essential for conveying important information to distributors, consumers, and regulatory parties. Errors like typos, misprints, and incorrect bar codes can lead to confusion, regulatory issues, and loss of customer trust. For example, a typo in nutritional information can mislead consumers, while an incorrect SKU might result in inventory mismanagement.

To minimize labeling errors, implement rigorous review and proofing processes. This includes having multiple team members check labels for accuracy and readability before final approval. Utilizing digital tools and software for label design can also help you identify potential inconsistencies early on. By prioritizing accuracy in labeling, you can enhance transparency and trust with your distributors and customers.

Missing Product Information

Omitting crucial product information from your packaging can have serious ramifications. For food products, the absence of nutritional information can be a regulatory violation. For items that are fragile or hazardous, missing warning labels can lead to mishandling, product damage, and other costly mistakes. Clear and comprehensive product information is vital for ensuring safe, responsible handling throughout the supply chain.

Make sure your packaging displays all necessary product information clearly and prominently. Labels should include all relevant nutritional facts, usage instructions, warnings, and any legal disclaimers required by law. Regular updates to your packaging content may be necessary to reflect changes in regulations or product formulations. By providing comprehensive information, you can foster consumer confidence and maintain compliance with industry standards.

Using Weak or Inconsistent Stretch Wrapping

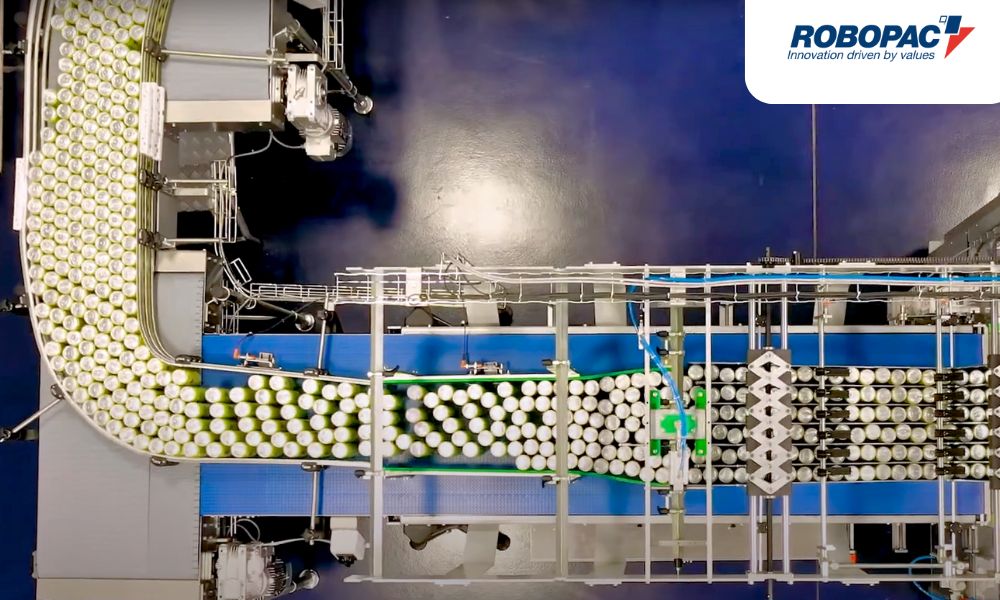

Proper stretch wrapping is essential for securing products during transportation. Weak or inconsistent wrapping can increase the risk of damage, leading to higher costs and customer dissatisfaction. Manual wrapping methods often result in uneven tension and coverage, which can compromise the integrity of the packaging.

Investing in stretch wrap machines can significantly improve the quality and consistency of wrapping processes. These machines ensure uniform tension and coverage, providing a secure wrap that protects products throughout their journey. By automating the wrapping process, your business can reduce the likelihood of product damage and improve operational efficiency.

Neglecting Quality Control

Quality control is a critical component of the packaging process that ensures each product meets the high standards customers expect. Without it, mistakes such as incorrect labels, damaged cases, or unstable product loads can slip through the cracks and create serious consequences for your entire supply chain.

Implementing strong quality control policies is one of the best ways to avoid common packaging errors. Quality control processes help prevent supply chain accidents, product losses, and negative customer experiences. This protects both your customers and your business, creating a more positive and successful packaging operation overall.

Implementing quality control measures at multiple stages of the packaging process is key. This includes inspecting raw materials upon arrival, monitoring the packaging process, and conducting final checks before distribution. Investing in training for quality control personnel can further enhance the effectiveness of these measures. Proactive quality control not only prevents costly mistakes but also reinforces a commitment to excellence in the eyes of your customers.

Optimize Your Packaging Line With Robopac USA

The right equipment helps your business minimize mistakes and deliver consistent, reliable solutions for your supply chain. Explore premium secondary packaging equipment, such as our case packer machines, and optimize your workflow with Robopac USA.