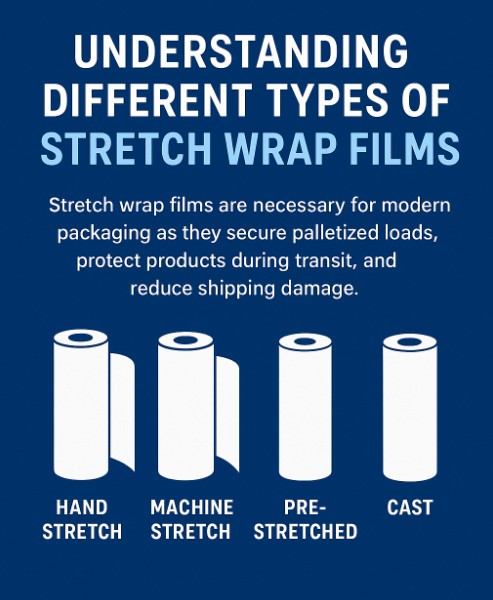

Stretch wrap films are necessary for modern packaging as they secure palletized loads, protect products during transit, and reduce shipping damage. However, there are many types of stretch wrap films to choose from, and a thorough understanding can help you decide. Below, we’ll break down the most common kinds, including their applications, advantages, and disadvantages.

Understanding Stretch Wrap Film and Its Importance

Stretch wrap film, made from linear low-density polyethylene, secures palletized loads by creating a containment force that holds products in place during transport and storage. Its stretch and recovery properties maintain load integrity without additional securing methods, offering protection against dust, moisture, and tampering while keeping products visible for easy inventory management.

Choosing the right stretch film is a key consideration of supply chain organization. Proper selection minimizes product damage, reduces rewrapping, and optimizes material usage, directly lowering packaging costs and increasing operational productivity.

Kinds of Stretch Wrap Films

There are many different types of stretch wrap films that logistic coordinators must understand when selecting the ideal film for their process. From hand stretch to machine stretch and specialty stretch films, there is no shortage of options to choose from.

Hand Stretch Film

Hand stretch film, also known as manual pallet wrap, is a versatile packaging solution for securing palletized loads without machinery. It is common in operations with low to moderate load volumes or when wrapping irregularly shaped items. It is ideal for small warehouses, retail settings, or other spaces where mechanical wrapping systems are not practical.

Pros of Hand Stretch Film

Hand stretch film is ideal for operations handling fewer than 15 loads per day. It is a cost-effective solution that eliminates the need for expensive wrapping machinery. It offers excellent versatility, making it suitable for irregularly shaped loads and adaptable to varying wrapping needs. Lightweight and easy to handle, hand stretch film is a convenient option for small teams or operations with limited space.

Cons of Hand Stretch Film

Manual wrapping is labor-intensive, as repeated application can cause operator fatigue and increase labor costs over time. It is also less efficient for businesses handling high volumes, where machine wrapping systems offer a more practical solution. Manual wrapping may also result in inconsistent coverage or improper containment due to variations in operator technique.

Machine Stretch Film

Machine stretch film is designed for industrial wrapping machines and is ideal for high-volume packaging operations. It provides consistent and efficient load containment, thanks to its ability to achieve high stretch ratios and maintain superior tension during application. This type of stretch film is common in manufacturing, distribution, and logistics, where securing large volumes of pallets or loads quickly and reliably is essential.

Pros of Machine Stretch Film

Machine stretch films offer numerous benefits for efficient packaging operations. With high stretch ratios of 200 to 300 percent, they reduce film consumption while ensuring strong load containment.

Automated wrapping provides consistent application by eliminating operator variability, guaranteeing uniform wrap patterns and tension for every load. The stretch capability results in significant material savings, using less film while maintaining stability and security for the load.

Cons of Machine Stretch Film

Stretch wrapping involves some challenges, including the need for an initial investment in stretch wrapping machines. These machines are best for operations with standardized load sizes and shapes, as irregular loads are difficult to handle. Operators must also conduct regular maintenance to ensure the consistent performance of these machines.

Pre-Stretched Film

Manufacturers stretch pre-stretched film during its creation process before winding it onto rolls. This eliminates the need for significant stretching during application, making it easier to use and highly efficient.

Pre-stretched film is common in packaging applications where secure load containment, material efficiency, and ease of application are priorities. It is especially popular in industries with high-volume wrapping needs or where sustainability is a focus.

Pros of Pre-Stretched Film

Pre-stretched film is easy to apply and requires less effort during manual wrapping. Its material efficiency is notable; it is thinner and lighter and uses less material without compromising strength, ultimately leading to cost savings. It is also a sustainable choice, using less material, reducing waste, and often incorporating recycled content.

The consistent thickness and tension also improve load appearance, delivering a clean, professional, and uniform wrap. These benefits, along with the lower material weight, reduce packaging costs and transportation expenses.

Cons of Pre-Stretched Film

Since it is already pre-stretched, this type of film has limitations for stretchability, making it less suitable for load types that require further elongation. The film also tends to have higher upfront costs than traditional stretch films. Its specialized usage may also make it less ideal for extremely heavy or irregular loads that need greater flexibility or stretch.

Cast Stretch Film

Cast stretch film is produced through cast extrusion. This process involves melting and pressing resin through a flat die onto a chilled roller. This creates a film with excellent clarity and consistent thickness, making it a popular choice for securing and protecting palletized loads during storage and transportation.

Pros of Cast Stretch Film

The film offers superior optical clarity, making barcode scanning and product identification easy without unwrapping. Its consistent thickness ensures uniform performance across the roll, reducing weak spots and enhancing load security.

Suitable for noise-sensitive environments, it unwinds quietly, making it a practical choice. It also performs reliably in varying temperatures, including cold storage, and its strong tear resistance effectively handles loads with sharp edges or protrusions.

Cons of Cast Stretch Film

Cast films have some limitations in comparison to blown films. They may offer lower puncture resistance under extreme conditions, making them more prone to damage. They also have a lower stretch recovery, which can impact their ability to maintain tight wraps over time in certain applications. The unique production process of cast films can also mean higher costs for specific uses.

Specialty Stretch Films

We’ve covered many of the basic films, but there is a plethora of specialty films for distinct applications. These films enhance performance for specific industries, ensuring protection, security, and efficiency. Examples of specialty films include the following:

- Ultra-violet inhibitor (UVI) film: UVI film protects loads from sun damage with UV-blocking additives and is ideal for agricultural and construction storage.

- Vapor corrosion inhibitor (VCI) films: VCI film releases vapors to prevent metal corrosion during storage and shipping. It is applicable for the automotive, machinery, and metal industries.

- Anti-static film: Anti-static film prevents static buildup to protect sensitive electronics from electrostatic discharge. It’s useful for the electronics and semiconductor industries.

- Opaque film: Opaque film conceals load contents for security and theft prevention and is suitable for high-value or confidential shipments.

- Vented film: Vented film features perforations for airflow, maintaining product quality for fresh produce or items requiring circulation.

Optimizing Your Packaging Operations

Choosing the right stretch wrap film can turn packaging from a cost into a competitive advantage by enhancing load security, reducing material costs, improving efficiency, and supporting sustainability. Understanding the characteristics of each stretch wrap film helps align choices with operational needs and business goals.

At Robopac USA, we’re experts in stretch wrapping, including machinery and equipment. View our automatic wrappers and more online, or contact our staff for help optimizing your packaging operations.