Choosing the right stretch wrapping solution is crucial to enhancing packaging efficiency and controlling costs. But what are the differences between manual and semiautomatic stretch wrappers, and which solution is best for your application? Our guide will help you understand each method and which one is ideal for you.

Understanding Manual Stretch Wrapping

Manual stretch wrapping requires operators to physically walk around pallets while applying stretch film by hand, using minimal equipment such as a handheld dispenser. It’s an effective option for operations handling fewer than 15 loads per day, and it provides operators with full control over film application, including tension and coverage adjustments for specific load needs.

However, manual wrapping demands significant physical effort and time while presenting consistency challenges. Variations in film tension can cause inconsistent load containment, which risks product protection during shipping and increases material waste.

Semiautomatic Stretch Wrapper Advantages

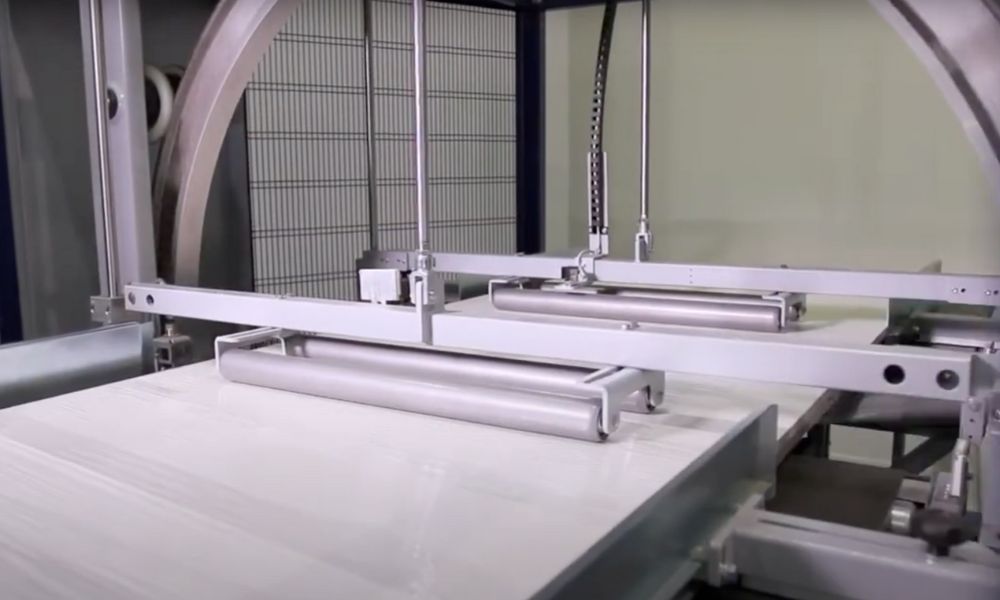

Semiautomatic stretch wrappers streamline the packaging process by automating film application while allowing operators to position loads and initiate cycles. These machines, which can feature turntables, rotary arms, or horizontal configurations, ensure consistent tension and coverage, reducing the physical strain of manual wrapping and improving efficiency.

Ideal for operations handling 15 to 50 loads daily, semiautomatic systems save time and enhance consistency without the high costs of full automation. They’re practical solutions for bridging the gap between manual wrapping and fully automated systems, delivering reliable performance and improved productivity.

Operational Impact of Manual vs. Semiautomatic Stretch Wrapping

The productivity gap between manual and semiautomatic wrapping is clear. Manual wrapping takes 3 to 5 minutes per pallet, while semiautomatic machines complete the job in just 60 to 90 seconds. Beyond time savings, semiautomatic machines also reduce worker fatigue and the risk of repetitive motion injuries.

Semiautomatic systems are also more efficient with film usage. Their consistent mechanical application minimizes waste and ensures proper load containment.

Investment and ROI Considerations

Another key difference between manual and semiautomatic stretch wrappers to consider is the investment and return on investment (ROI). Manual wrapping is cost effective upfront, but labor costs and inconsistent results can add up over time. Semiautomatic stretch wrappers require a moderate initial investment, but they return the investment through labor savings and efficiency.

Manual systems also need little upkeep, while semiautomatic machines require regular maintenance to ensure reliability. With sufficient maintenance, however, semiautomatic equipment minimizes downtime and offers a dependable solution for growing operations.

Making the Right Choice for Your Operation

When you’re deciding which stretch wrapping method best fits your application and process, there are a few factors to consider. For operations packaging fewer than 10 loads daily, manual methods may suffice; facilities that handle 20 or more loads per day can benefit greatly from semiautomatic systems. Semiautomatic machines are also better for growing businesses, as they can handle increased volumes more efficiently and provide scalability to meet evolving needs.

Workforce considerations are equally important. Semiautomatic systems mitigate challenges such as labor shortages and high turnover by reducing reliance on skilled manual labor.

Optimizing Your Packaging Investment

Choosing between manual and semiautomatic stretch wrappers comes down to balancing your current needs with future growth. By analyzing your current wrapping costs—including labor, material use, and quality issues—you can better justify the decision and set realistic ROI expectations. If you’re ready to upgrade your packaging process, contact Robopac USA today to find the perfect stretch wrapping solution for your business.