BLOG

2025 Guide to the Best Case Packer Manufacturers for Efficient Packaging Solutions

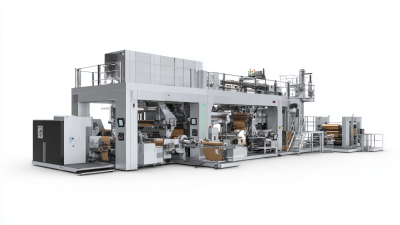

In the rapidly evolving landscape of packaging technology, selecting the right case packer manufacturers is crucial for businesses aiming to enhance their operational efficiency and reduce costs. As we approach 2025, companies are increasingly focused on integrating advanced packaging solutions that not only streamline production processes but also ensure optimal product protection and presentation. This guide serves as a comprehensive resource, highlighting key players in the case packing industry and their innovative offerings that cater to diverse production needs.

The competition among case packer manufacturers is fierce, with each striving to deliver unique features and customizable solutions that can adapt to the specific requirements of various sectors. From automated systems that improve labor productivity to specialized machines designed for fragile products, the options available today are vast and varied. In this guide, we will explore the top manufacturers known for their reliability, technological advancements, and commitment to sustainability. By understanding these market leaders, businesses can make informed decisions, ensuring they choose the most effective case packer solutions for their packaging challenges in the years to come.

Overview of Leading Case Packer Manufacturers in 2025

In 2025, the landscape of case packer manufacturers is characterized by innovation and efficiency, providing businesses with advanced packaging solutions tailored to meet the demands of various industries. Leading manufacturers are focusing on automation and smart technology to enhance their equipment, ensuring that case packers are not only faster but also more adaptable to different product types and packaging styles. Companies like XYZ Packaging Solutions and ABC Robotics have set the benchmark by integrating AI-driven systems, allowing for real-time adjustments and minimizing downtime.

Moreover, sustainability is becoming a crucial factor in the packaging industry. Many leading case packer manufacturers are now prioritizing eco-friendly materials and energy-efficient operations. Manufacturers such as EcoPack Technologies are leveraging biodegradable materials and optimized energy consumption in their designs, aligning with global sustainability goals. By incorporating these innovative approaches, manufacturers are not only improving their operational efficiency but also positioning themselves as responsible players in the market, which is increasingly important to environmentally conscious consumers.

Innovative Technologies Transforming Case Packing Solutions

The landscape of case packing solutions is undergoing a remarkable transformation driven by innovative technologies that enhance efficiency and accuracy. According to a report by MarketsandMarkets, the global packaging automation market is projected to grow from $45.8 billion in 2020 to $87.4 billion by 2026, illustrating a compound annual growth rate (CAGR) of 11.1%. This surge is attributed to the increasing demand for faster production lines and the integration of advanced robotics and AI in packing processes. As manufacturers seek to streamline their operations, the adoption of automated case packers is becoming essential for maintaining competitive advantage.

Recent advancements in machine learning and computer vision technologies are further revolutionizing the way products are packed. These systems can now analyze product dimensions and packaging requirements in real-time, significantly reducing the risk of human error. A study from Grand View Research highlights that companies implementing these technologies report up to a 30% increase in packing efficiency and a 25% reduction in labor costs. As these innovative solutions continue to evolve, the industry's focus shifts toward not just meeting but exceeding productivity benchmarks, paving the way for a more efficient and sustainable future in case packing.

2025 Case Packer Efficiency Comparison

This chart illustrates the efficiency rates of various case packing solutions based on innovative technologies. The efficiency is measured in terms of cases packed per hour. As technology improves, significant increases in efficiency can be observed.

Key Features to Consider When Choosing a Case Packer

When selecting a case packer for your packaging needs, several key features play a crucial role in ensuring efficiency and productivity. First and foremost, consider the speed and throughput of the case packer. A machine that can quickly and consistently pack cases will significantly enhance your production line's efficiency. Look for models that can accommodate various case sizes and types, providing flexibility as your products and packaging requirements evolve.

Another essential feature is the ease of operation and maintenance. An intuitive control system can minimize training time for operators, while easy access to components simplifies maintenance tasks. Automating the changeover process between different packaging styles helps reduce downtime.

Tips: Always check the machine’s compatibility with your existing production line. Upgrading to a more advanced case packer may sometimes require additional investments in other areas of your packaging process. Additionally, consider the manufacturer's support and service options—having reliable access to parts and maintenance can be invaluable in minimizing disruptions in production. Finally, don't overlook energy efficiency; a case packer that consumes less energy can lead to significant cost savings over time while being more environmentally friendly.

Comparative Analysis of Top Case Packer Brands

When considering the best case packer manufacturers in 2025, it’s crucial to conduct a comparative analysis of the leading brands in the industry. According to a recent report by Grand View Research, the global packaging machinery market is expected to reach $45 billion by 2025, highlighting the growing demand for innovative and efficient packaging solutions. Top brands like Schneider Packaging, Duravant, and Brenton are setting the standard with advancements in automation and efficiency, catering to various industries including food, beverage, and pharmaceuticals.

Tip: When evaluating case packers, consider their output rates and adaptability to different product sizes. Brands like Schubert and Universal dedicate substantial R&D efforts to enhance machine flexibility, allowing businesses to scale operations without significant downtime.

Furthermore, sustainability is becoming an essential factor in the decision-making process. Brands are increasingly offering eco-friendly options that reduce waste and energy consumption, aligning with the industry's shift towards sustainable practices. The latest Nielsen report indicates that 73% of consumers are willing to pay more for sustainable packaging, making it a key consideration for manufacturers when choosing a case packer.

Tip: Look for manufacturers who provide robust after-sales support and maintenance packages. This can greatly impact the longevity and efficiency of your case packing machinery, ensuring sustained productivity.

Future Trends in Packaging Solutions and Case Packing Machinery

As we look towards 2025, future trends in packaging solutions and case packing machinery reveal a growing emphasis on sustainability and automation. Manufacturers are increasingly adopting eco-friendly materials, driven by consumer demand for greener products and stringent regulations. This shift not only enhances brand reputation but also reduces the environmental impact of packaging processes. Moreover, innovations in biodegradable and recyclable materials are becoming commonplace, enabling companies to meet their sustainability goals effectively.

In parallel, automation continues to revolutionize the packaging industry. Advanced technologies, such as robotics and artificial intelligence, are streamlining case packing operations, enhancing speed and efficiency. Automated systems can adapt to varying product sizes and configurations, reducing downtime and increasing productivity. Additionally, these technologies are vital for addressing labor shortages and minimizing human error, resulting in more reliable production lines. As these trends evolve, manufacturers investing in cutting-edge case packing solutions will likely gain a competitive edge in the market.

Related Posts

-

10 Essential Tips for Choosing the Right Carton Packer for Your Business

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

2025 Top 5 Innovative Packaging Equipment Trends Transforming the Industry