BLOG

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

The rapid evolution of the global packaging industry is fundamentally transforming how businesses approach their packaging strategies. With the market for automated packaging solutions projected to reach $65 billion by 2026, growing at a CAGR of 13.9%, it is clear that investing in advanced technologies is no longer optional for modern enterprises. Automation not only enhances operational efficiency but also reduces human error and labor costs, aligning with the growing demand for environmentally sustainable practices.

According to a recent study by Smithers Pira, 40% of manufacturers are already leveraging automated packaging systems to streamline their operations, indicating a strong trend towards digitization and efficiency. As businesses increasingly seek to optimize their supply chains and improve product delivery times, the adoption of these cutting-edge automated packaging solutions stands at the forefront of industrial modernization.

The Impact of Automation on Packaging Speed and Quality

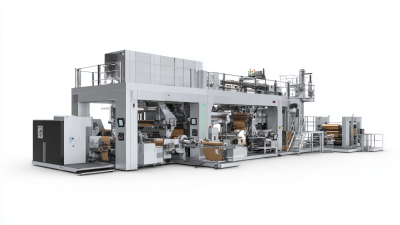

The impact of automation on packaging speed and quality is profound and transformative for modern businesses. Automated packaging solutions have drastically reduced the time required for packaging processes, enabling companies to meet the rising demand for quick turnaround times. With machines handling everything from filling to sealing and labeling, businesses can significantly accelerate their production lines, ensuring that products are ready for distribution in record time. This efficiency not only enhances productivity but also allows companies to respond more swiftly to market changes and customer needs.

In addition to speed, automation significantly improves the quality of packaging. Automated systems are designed to operate with precision, minimizing human errors that can lead to product damage or inconsistencies. This high level of accuracy ensures that each package meets regulatory standards and customer expectations, ultimately enhancing brand reputation. Furthermore, advanced technologies such as machine vision and sensors allow for real-time quality checks, ensuring that any defects are detected and addressed immediately. As businesses increasingly adopt automated packaging solutions, they are not only revolutionizing their operational efficiency but also setting new benchmarks for quality in the industry.

Advancements in Robotics for Streamlined Packaging Processes

The packaging industry is undergoing a transformative shift with the integration of advanced robotics technology. Recent statistics indicate that the packaging robots market is projected to reach an impressive USD 19.0 billion by 2033. This growth is fueled by the demand for streamlined operations, which significantly enhance productivity while reducing labor costs. With the rise of artificial intelligence, applications such as machine learning and predictive analytics are optimizing packaging processes to meet modern business needs.

As automation continues to evolve, the packaging automation market is anticipated to soar to USD 52.2 billion. The drive towards precision and efficiency in operations is imperative to remaining competitive in today’s marketplace. Warehouse robotics also play a crucial role in this transformation, increasing accuracy and helping businesses effectively manage their supply chain challenges.

Tips for Implementing Intelligent Robotics:

- Assess your current packaging processes and identify areas that could benefit from automation.

- Invest in training for your workforce to ensure a smooth transition to automated systems.

- Stay updated on emerging technologies in robotics to leverage new advancements that can optimize efficiency further.

Integrating Smart Technology for Real-Time Packaging Optimization

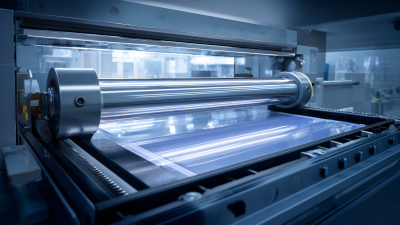

The integration of smart technology in automated packaging solutions has become a game changer for modern businesses aiming to enhance efficiency and reduce waste. As the AI in Packaging market continues to grow, technologies such as machine learning, computer vision, and predictive analysis are driving real-time packaging optimization. With modern warehouses generating approximately 2.5 million tonnes of operational waste annually in the UK alone, optimizing packaging processes can significantly minimize waste associated with packaging materials.

The integration of smart technology in automated packaging solutions has become a game changer for modern businesses aiming to enhance efficiency and reduce waste. As the AI in Packaging market continues to grow, technologies such as machine learning, computer vision, and predictive analysis are driving real-time packaging optimization. With modern warehouses generating approximately 2.5 million tonnes of operational waste annually in the UK alone, optimizing packaging processes can significantly minimize waste associated with packaging materials.

Companies looking to leverage smart technology in their packaging processes can consider implementing AI-driven systems to automate workflows and optimize inventory management. According to recent industry reports, the digital liquid filling systems market is projected to reach USD 6.7 billion by 2035, growing at a CAGR of 4.0%. This growth highlights the increasing demand for advanced packaging solutions that ensure efficiency and sustainability.

Tips: To effectively adopt these technologies, businesses should invest in workforce upskilling to ensure employees are equipped with the necessary skills to operate sophisticated AI tools. Additionally, exploring flexible packaging options with integrated smart features like freshness sensors can further enhance product integrity and consumer satisfaction.

Cost-Benefit Analysis of Automated vs. Manual Packaging Systems

The cost-benefit analysis of automated versus manual packaging systems reveals significant advantages for modern businesses aiming for efficiency. With the global food automation market projected to reach a staggering value of $8.983 billion by 2025 and an anticipated growth rate leading to $12.2 billion by 2033, companies are increasingly recognizing the importance of automating their packaging processes. The compound annual growth rate (CAGR) of 3.9% highlights not only the rising demand for automation but also underscores the cost savings and scalability benefits it presents.

In addition, the returnable transport packaging (RTP) sector shows promising growth, with estimates suggesting an increase from $25.25 billion in 2025 to $35.5 billion by 2033, a CAGR of 4.35%. This trend indicates that businesses are shifting towards sustainable and reusable packaging solutions, facilitating cost savings and reducing waste. Furthermore, the aerosol filling machine market is expected to grow from $2.08 billion in 2022 to $2.95 billion by 2030, with a CAGR of 4.61%. Collectively, these statistics emphasize the critical role of automated systems in enhancing operational efficiency and delivering substantial economic benefits in the evolving packaging landscape.

Sustainability Practices in Modern Automated Packaging Solutions

The modernization of automated packaging solutions is increasingly intertwined with sustainability practices, directly addressing the environmental challenges that contemporary businesses face. This shift is propelled by advanced technologies that not only enhance operational efficiency but also minimize waste and carbon footprint. Innovations in pharmaceutical and e-commerce packaging are setting benchmarks for sustainability by utilizing eco-friendly materials and design practices that prioritize resource conservation. This focus on reducing landfill waste and emissions is essential in an age where environmental consciousness is paramount.

Moreover, the rise of right-sized automated packaging systems embodies this commitment to sustainability. These systems optimize packaging dimensions to ensure materials are used efficiently, leading to a significant reduction in excess packaging. As a result, companies can lower their labor costs while improving overall packing speed and efficiency. The integration of smart automation technologies in fulfillment processes enables businesses to balance the demands of rapid delivery with sustainable practices, ultimately contributing to a more sustainable future for various industries.

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses - Sustainability Practices in Modern Automated Packaging Solutions

| Dimension | Data Type | Sustainability Efforts | Impact Metrics |

|---|---|---|---|

| Packaging Material | Biodegradable | Use of recycled materials | Reduction of plastic waste by 30% |

| Automation Technology | AI & Robotics | Energy-efficient robotics | Energy consumption reduced by 25% |

| Supply Chain Management | Optimized Logistics | Local sourcing | CO2 emissions decreased by 15% |

| Waste Management | Recycling | Zero waste initiatives | Landfill waste down by 40% |

| Energy Use | Renewable Sources | Solar and wind energy | Renewable energy usage at 60% |