BLOG

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper

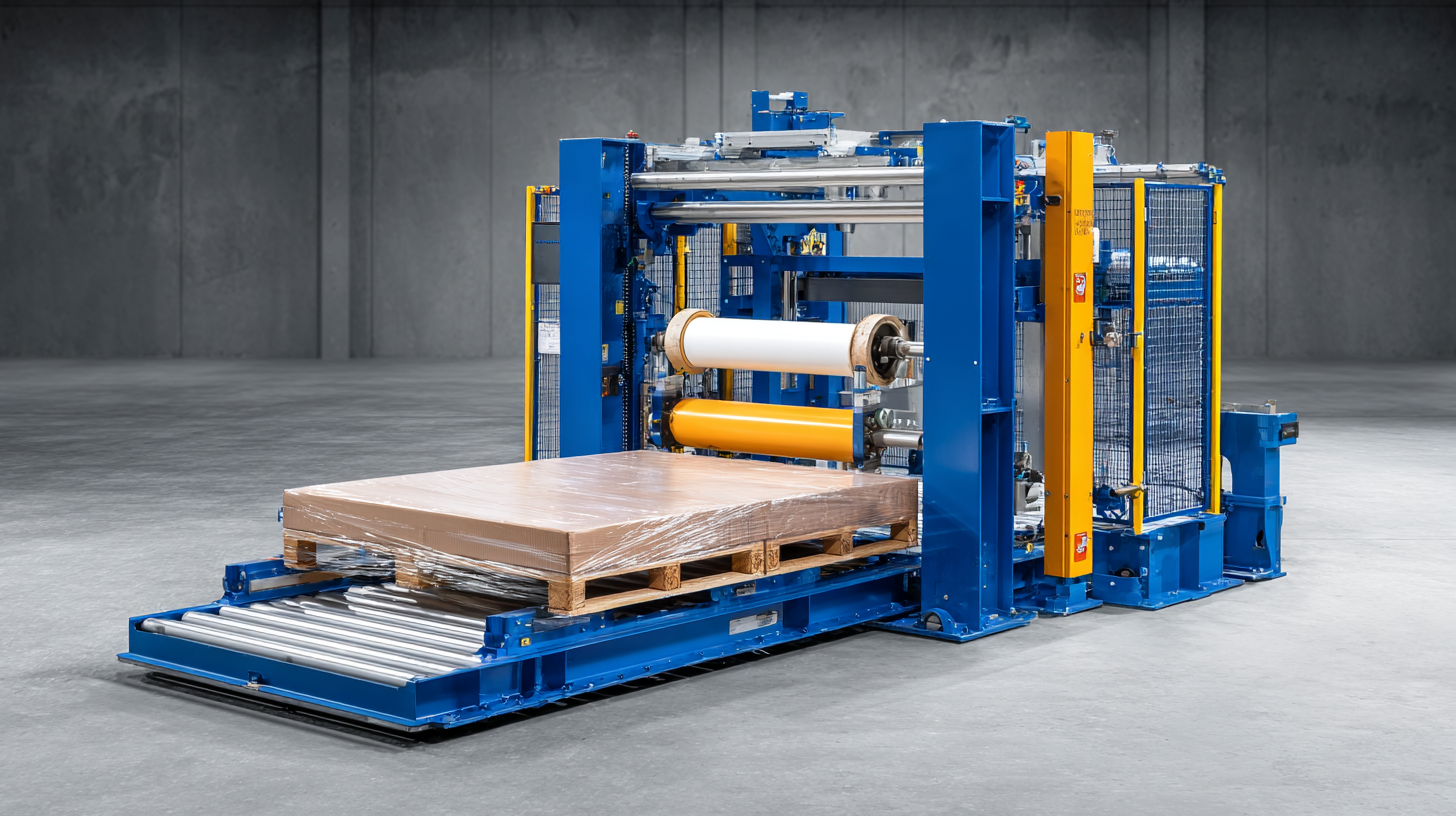

In today's fast-paced logistics and manufacturing environments, efficiency and safety play pivotal roles in operational success. An automatic pallet wrapper is a transformative tool that streamlines the palletizing process, enhancing productivity and reducing labor costs. According to a report by Freedonia Group, the demand for automated packaging equipment, including automatic pallet wrappers, is projected to grow by 4.6% annually through 2024. This growth is fueled by an increasing need for improved supply chain efficiency and reduced material wastage.

Moreover, the International Journal of Advanced Manufacturing Technology highlights that automation in packaging can lead to a 30% reduction in packaging time and a significant decrease in product damage during transit. By integrating an automatic pallet wrapper into their operations, businesses not only optimize their processes but also ensure greater safety and consistency in packaging, ultimately contributing to a smoother and more efficient supply chain.

Understanding the Key Advantages of Automatic Pallet Wrappers

Automatic pallet wrappers are revolutionizing the way businesses handle their packaging processes. The key advantages of these machines lie in their ability to enhance efficiency, reduce labor costs, and improve packaging consistency. With an automatic pallet wrapper, products can be securely wrapped in a fraction of the time it would take manually, thereby increasing throughput and ensuring that goods are well-protected during transportation.

**Tip:** When selecting an automatic pallet wrapper, consider the volume of pallets you need to wrap daily. This will help you choose a model that meets your operational demands without compromising on performance.

Another significant benefit of automatic pallet wrappers is the reduction of material waste. These machines are designed to optimize film usage, ensuring that the exact amount of stretch film needed is applied, which not only minimizes costs but also contributes to sustainability efforts. Furthermore, the consistent wrapping quality strengthens pallet stability, reducing the risk of damage during transit.

**Tip:** Regular maintenance and timely calibration of your automatic pallet wrapper can ensure consistent performance and longevity of the equipment, thus maximizing your investment.

The Benefits of Using Automatic Pallet Wrappers

How Automatic Pallet Wrappers Enhance Efficiency in Packaging

Automatic pallet wrappers are revolutionizing the packaging industry, significantly enhancing efficiency and productivity. According to a study by the National Association of Manufacturers, companies utilizing automated packaging solutions can increase output by up to 25%. This boost in performance is largely attributed to the speed and precision of automatic pallet wrappers, which can wrap an average of 30 to 100 pallets per hour compared to manual wrapping processes that take considerably longer. The automation not only streamlines operations but also reduces labor costs associated with manual packing.

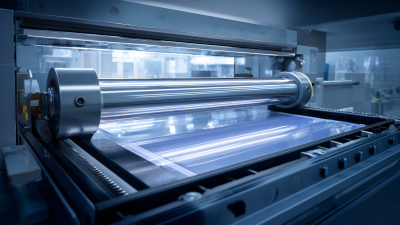

Moreover, automatic pallet wrappers contribute to consistent packaging quality, which is vital for maintaining product integrity during transport. A report from the Packaging Machinery Manufacturers Institute (PMMI) highlights that automated systems can minimize film usage by 20% due to precision application, resulting in significant material savings and reduced environmental impact. This efficiency extends to improving the overall sustainability of packaging processes, with many companies achieving better compliance with environmental standards through reduced waste and lower energy consumption. The implementation of automatic pallet wrappers is therefore a strategic move for businesses looking to enhance their packaging efficiency while simultaneously promoting sustainability.

Moreover, automatic pallet wrappers contribute to consistent packaging quality, which is vital for maintaining product integrity during transport. A report from the Packaging Machinery Manufacturers Institute (PMMI) highlights that automated systems can minimize film usage by 20% due to precision application, resulting in significant material savings and reduced environmental impact. This efficiency extends to improving the overall sustainability of packaging processes, with many companies achieving better compliance with environmental standards through reduced waste and lower energy consumption. The implementation of automatic pallet wrappers is therefore a strategic move for businesses looking to enhance their packaging efficiency while simultaneously promoting sustainability.

Comparing Manual vs. Automatic Wrapping: What You Need to Know

When considering packaging options, the choice between manual and automatic pallet wrapping is crucial for efficiency and cost-effectiveness. Manual wrapping, while less expensive upfront, demands significant labor resources. According to a study by the Packaging Machinery Manufacturers Institute (PMMI), companies utilizing manual wrapping often experience up to 30% higher labor costs due to the time-intensive nature of the process. This can lead to increased operational fatigue and ultimately affect productivity.

In contrast, automatic pallet wrappers significantly streamline the wrapping process. Research from the Food and Beverage Industry indicates that automatic systems can wrap pallets 2 to 3 times faster than manual efforts, reducing labor costs by roughly 50%. Moreover, these systems offer consistent tension and coverage, reducing the likelihood of product damage during transportation. The investment in an automatic wrapper can result in a return on investment (ROI) within the first year, due to lower labor costs and enhanced efficiency.

Cost Savings and Increased Productivity with Automatic Pallet Wrappers

Automatic pallet wrappers are revolutionizing the packaging industry by significantly enhancing cost savings and boosting productivity in warehouses and manufacturing facilities. One of the most notable benefits is the reduction in labor costs. Traditional manual wrapping methods require multiple workers to wrap pallets securely, which can be time-consuming and inefficient. By investing in an automatic pallet wrapper, companies can streamline their operations, allowing a single operator to manage the wrapper while focusing efforts on other high-value tasks. This shift not only saves on labor costs but also minimizes the risk of injuries associated with manual handling.

Automatic pallet wrappers are revolutionizing the packaging industry by significantly enhancing cost savings and boosting productivity in warehouses and manufacturing facilities. One of the most notable benefits is the reduction in labor costs. Traditional manual wrapping methods require multiple workers to wrap pallets securely, which can be time-consuming and inefficient. By investing in an automatic pallet wrapper, companies can streamline their operations, allowing a single operator to manage the wrapper while focusing efforts on other high-value tasks. This shift not only saves on labor costs but also minimizes the risk of injuries associated with manual handling.

Moreover, automatic pallet wrappers improve material efficiency, reducing waste and ensuring that packaging materials are used effectively. Advanced machines provide consistent tension and coverage during the wrapping process, leading to fewer faulty wraps and damaged goods. As a result, companies can experience lower shipping costs due to reduced freight claims and product losses. The efficiency and reliability offered by automatic pallet wrappers also contribute to faster turnaround times, enabling businesses to meet tight deadlines and respond swiftly to market demands, ultimately enhancing their competitiveness in an ever-evolving industry landscape.

Safety Benefits of Using Automatic Pallet Wrappers in Your Warehouse

Automatic pallet wrappers are becoming increasingly essential in warehouses, primarily due to the significant safety benefits they offer. Data from the Occupational Safety and Health Administration (OSHA) indicates that manual pallet wrapping can lead to numerous workplace injuries, including musculoskeletal disorders and accidents related to slips and falls. By automating this process, companies can drastically reduce the risk of injuries among their workforce. In fact, studies show that implementing an automatic pallet wrapper can cut the incidence of these injuries by up to 40%, creating a safer work environment for all employees.

Tips for ensuring maximum safety when using automatic pallet wrappers include conducting regular maintenance checks to ensure the machinery is functioning correctly and safely. Additionally, training staff on the proper use of these machines can further minimize risk. It’s vital to keep the area around the pallet wrapper clean and organized to prevent trips and falls, as clutter can pose a significant hazard.

Another advantage of automatic pallet wrappers is their ability to improve operational efficiency while enhancing safety. By streamlining the wrapping process, workers can focus more on other critical tasks and less on repetitive actions that could lead to injury. In a recent industry report, it was noted that warehouses using automatic wrapping solutions saw a productivity increase of up to 30%, alongside a notable decrease in safety incidents, reinforcing the dual benefits of adopting this technology.

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper - Safety Benefits of Using Automatic Pallet Wrappers in Your Warehouse

| Benefit Category | Specific Benefits | Impact on Warehouse Safety |

|---|---|---|

| Injury Reduction | Less manual lifting and wrapping | Decreased risk of muscle strains |

| Improved Ergonomics | Automated wrapping process | Reduction of repetitive stress injuries |

| Enhanced Stability | Consistent wrapping tension | Less chance of load shifting during transport |

| Increased Efficiency | Faster pallet wrapping process | Reduced time spent on manual tasks |

| Safety Compliance | Easier adherence to safety regulations | Lower risk of penalties and accidents |

| Reduced Downtime | Fewer accidents and injuries | Mediums to maintain workforce efficiency |

Related Posts

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency