BLOG

2025 Top 5 Innovative Packaging Equipment Trends Transforming the Industry

In the rapidly evolving landscape of the packaging industry, staying ahead of the curve is essential for manufacturers and businesses alike. As we approach 2025, innovative packaging equipment emerges as a driving force, reshaping how products are packaged, stored, and delivered. The integration of cutting-edge technologies and sustainable practices is not merely a trend but a necessity to meet the ever-growing demands for efficiency, sustainability, and consumer satisfaction.

This overview will delve into the top five innovative packaging equipment trends that are set to transform the industry. From automation and smart technologies to eco-friendly materials and customization, these advancements play a pivotal role in streamlining operations and enhancing product appeal. As we explore these key trends, it becomes clear that the future of packaging equipment is not just about functionality; it's about creating a more efficient, responsive, and environmentally conscious approach to packaging that aligns with today’s market expectations.

Emerging Role of Robotics in Streamlining Packaging Processes for Efficiency

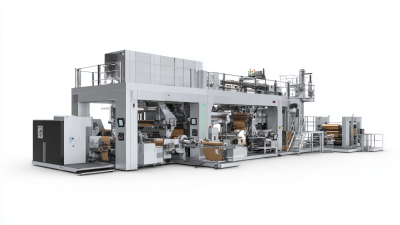

The rise of robotics in packaging processes is revolutionizing the industry by enhancing efficiency and streamlining operations. As manufacturers face increasing demands for faster production and custom packaging solutions, robotics plays a crucial role. Automated systems are now capable of performing tasks such as loading, packing, and sorting at unprecedented speeds, significantly reducing labor costs and errors. This trend is reshaping how companies manage their packaging lines, allowing for more flexible production schedules and improved responsiveness to market changes.

Innovations like automated packaging technologies are proving essential in sectors such as snacks and bakery operations, where companies need to meet diverse consumer preferences while maintaining efficiency. The development of advanced robotics systems enables manufacturers to quickly adapt to new product lines without extensive downtimes. Furthermore, this automation allows workers to focus on more strategic tasks, effectively transforming labor dynamics within the industry. As we look toward 2025 and beyond, the integration of robotics into packaging processes is set to continue driving operational improvements and shaping a more efficient future for the industry.

2025 Top 5 Innovative Packaging Equipment Trends

The following chart illustrates the projected impact of innovative packaging equipment trends, emphasizing the emerging role of robotics in enhancing efficiency within the packaging industry over the next few years.

The Impact of IoT Integration on Real-time Monitoring and Traceability in Packaging

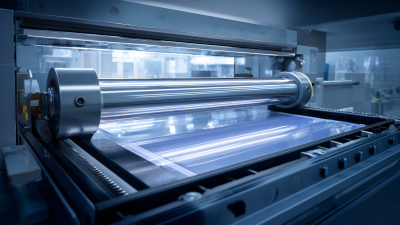

The integration of the Internet of Things (IoT) in packaging equipment is revolutionizing the industry by enabling real-time monitoring and enhanced traceability. With IoT sensors, manufacturers can track environmental conditions such as temperature, humidity, and location throughout the supply chain. This data not only ensures that products are stored and transported under optimal conditions, but also allows for immediate responses to any discrepancies that may threaten product quality.

Moreover, IoT facilitates an unprecedented level of transparency, greatly benefiting both producers and consumers. By connecting packaging to the cloud, stakeholders can gain access to comprehensive data analytics, enabling them to make informed decisions based on real-time information. For consumers, this traceability enhances trust, as they can verify the origin and handling of products before purchase. In an increasingly competitive market, such innovations are essential for companies looking to improve efficiency, reduce waste, and maintain high standards of safety and quality in their packaging processes.

Sustainable Packaging Solutions: Innovations in Materials and Waste Reduction Efforts

The packaging industry is undergoing a significant transformation as sustainability takes center stage. With a global sustainable pharmaceutical packaging market projected to reach USD 92 billion by 2024, innovative materials and practices are reshaping how products are packaged. The debate surrounding packaging waste is intensifying, particularly in Europe, as stakeholders explore solutions to achieve a circular economy. Technological advancements, such as AI and IoT, are enhancing the efficiency of packaging processes and enabling more sustainable practices. Companies are increasingly adopting eco-friendly materials, including paper-based packaging and biodegradable options, to align with consumer demand for greener solutions.

**Tips for Sustainable Packaging:**

1. Incorporate innovative materials like seaweed and mycelium to create biodegradable packaging options.

2. Implement a refillable system to reduce overall packaging waste and encourage customer loyalty.

3. Leverage technologies that enhance recycling efforts, making it easier for consumers to dispose of packaging responsibly.

These efforts are further exemplified by major brands committed to reducing packaging waste. By focusing on waste reduction and recycling initiatives, businesses not only contribute to environmental sustainability but also respond to a growing market that increasingly values eco-conscious practices in packaging. With continuous innovations and a commitment to sustainability, the packaging industry is poised for a greener future.

2025 Top 5 Innovative Packaging Equipment Trends Transforming the Industry

| Trend | Description | Key Benefits | Projected Adoption Rate (by 2025) |

|---|---|---|---|

| Smart Packaging Technology | Integration of sensors and QR codes to enhance consumer engagement and product tracking. | Improved customer experience, better inventory management, and real-time data access. | 45% |

| Biodegradable Materials | Use of materials that decompose naturally, minimizing environmental impact. | Reduced plastic waste, improved sustainability image, and compliance with regulations. | 55% |

| Reduced Packaging Waste | Innovations aimed at minimizing packaging while maintaining functionality. | Cost savings, decreased raw material use, and enhanced transport efficiency. | 60% |

| Reusable Packaging Solutions | Design of packaging systems that can be reused multiple times before disposal. | Long-term cost efficiency and reduced waste in supply chains. | 40% |

| Automation in Packaging | Implementation of advanced robotics and AI to streamline packaging processes. | Increased efficiency, reduced labor costs, and minimized error rates. | 50% |

AI and Machine Learning: Enhancing Predictive Maintenance and Performance Optimization in Packaging

The integration of AI and machine learning into the packaging industry is set to revolutionize operations, particularly through enhanced predictive maintenance and performance optimization. By utilizing advanced algorithms, companies can foresee equipment failures before they occur, thereby minimizing downtime and ensuring smooth production processes. This shift not only boosts efficiency but also significantly reduces operational costs, allowing businesses to respond agilely to market demands.

Tips: When considering AI implementation, focus on training data quality—more accurate insights stem from robust datasets. Additionally, engage staff in AI initiatives; human expertise is crucial for interpreting AI findings effectively.

Moreover, the AI-powered automation boom is transforming workflows beyond mere packaging. It enhances inventory management and streamlines supply chains, resulting in a seamless flow of products from manufacturers to consumers. With these technologies, manufacturers can achieve superior quality control while also improving sustainability through optimized resource usage.

Tips: Regularly analyze AI performance to fine-tune algorithms and ensure they evolve with changing market conditions. Partnering with technology providers can also accelerate adoption and help tailor solutions specifically to your operational needs.

Smart Packaging Technologies: Enhancing Consumer Engagement and Product Safety through Digital Solutions

The smart packaging market is poised for significant growth, with the industry projected to reach USD 38.1 billion by 2032. This surge is largely driven by advancements in digital solutions that enhance consumer engagement and improve product safety. Technologies such as machine learning, computer vision, and predictive analytics are at the forefront of this transformation, allowing brands to create more customized and interactive packaging experiences. Smart packaging not only improves brand interaction but also supports operational efficiency, providing a competitive edge in a rapidly evolving market.

Moreover, the integration of Internet of Packaging technologies is further expanding market opportunities. The global internet of packaging market, estimated at USD 21.05 billion in 2024, is expected to grow to USD 42.67 billion by 2033. This growth underscores the increasing importance of packaging that communicates, protects, and engages. As brands leverage these innovative solutions, the smart packaging sector is set to redefine how products connect with consumers, enhancing both safety and user experience in the process.

Related Posts

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

Optimizing Case Packing Efficiency: Insights from Recent Industry Reports and Best Practices