BLOG

Revolutionizing Warehouse Efficiency: The Science Behind Automatic Pallet Wrappers

In the fast-paced world of logistics and warehousing, efficiency is paramount, with companies continually seeking innovative solutions to enhance operational productivity. One such solution that has gained significant traction is the automatic pallet wrapper. According to a report by the Warehousing Education and Research Council (WERC), implementing automatic wrapping systems can reduce labor costs by up to 50% and increase throughput by 30%. Furthermore, a study from the Material Handling Industry of America (MHIA) highlights that automated systems contribute to a decrease in product damage rates by approximately 15%, ensuring that goods are delivered in optimal condition. As the demand for streamlined supply chain processes grows, the automatic pallet wrapper stands out as a transformative tool that not only improves efficiency but also supports sustainability by minimizing plastic waste through precise wrapping techniques. This alignment with industry standards illustrates the pivotal role that automatic pallet wrappers play in revolutionizing warehouse operations.

Understanding Automatic Pallet Wrappers: Key Components and Functionality

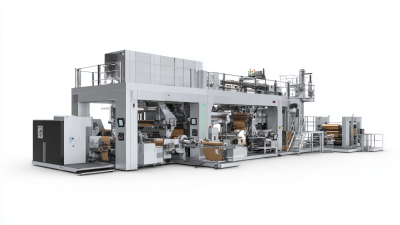

Automatic pallet wrappers have emerged as a crucial innovation in modern warehouse operations, significantly enhancing efficiency and productivity. These machines utilize advanced technology to securely wrap pallets with stretch film, ensuring that products are stabilized for storage and transport. According to a report by the Freedonia Group, the demand for stretch film in packaging applications is projected to reach over $4 billion by 2025, driven largely by innovations in automatic wrapping technology. This shift is transforming traditional warehousing practices, enabling quicker turnaround times and reduced labor costs.

The core components of automatic pallet wrappers include the stretch film dispenser, an adjustable platform, and advanced sensors that monitor wrapping tension and film quality. These features allow for customization based on the size and weight of the load, enhancing load stability during transport. A recent study conducted by the Material Handling Industry (MHI) indicates that automated systems can increase operational efficiency by up to 30%, reducing the time taken to wrap each pallet significantly when compared to manual wrapping methods. This not only streamlines workflow but also minimizes the risk of product damage, making automatic pallet wrappers an essential investment for warehouses aiming to optimize their processes.

Benefits of Using Automatic Pallet Wrappers in Warehouse Operations

Automatic pallet wrappers have become essential in modern warehouse operations, offering significant benefits that streamline processes and enhance efficiency. As businesses seek to adapt to increasing demands and labor shortages, these automated solutions play a critical role in optimizing packaging workflows. By using automatic pallet wrappers, warehouses can achieve substantial improvements in operational efficiency, which helps reduce labor costs and minimize material waste.

One of the key advantages of automatic pallet wrappers is their ability to enhance worker safety. By automating the wrapping process, warehouses reduce the physical strain on employees, thereby decreasing the risk of injury and improving overall ergonomics. With the growing emphasis on employee well-being, implementing these automated solutions not only boosts productivity but also fosters a safer working environment.

Tips: When considering the adoption of automatic pallet wrappers, assess your current workflow to identify bottlenecks that could be alleviated. Additionally, ensure that your staff is well-trained to operate these machines, as proper training will maximize the benefits of automation and enhance overall efficiency in warehouse operations.

How to Choose the Right Automatic Pallet Wrapper for Your Warehouse

Choosing the right automatic pallet wrapper for your warehouse involves several key considerations that can significantly impact efficiency and productivity. First, assess your specific needs based on the volume of goods you handle and the types of products being wrapped. Different wrappers come with various features, such as adjustable film tension and varying wrap speeds, which cater to different packaging requirements. It's crucial to select a machine that can accommodate the sizes and weights of your pallets to ensure optimal performance.

Another vital factor to consider is the technology behind the wrapper. Some automatic pallet wrappers utilize advanced sensors and controls that improve wrapping consistency and reduce material waste. Look for models that incorporate user-friendly interfaces, allowing for easy setup and operation. Lastly, consider the maintenance and service support offered by the manufacturer. A reliable supplier will ensure that you have access to timely repairs and parts, minimizing downtime and maximizing your warehouse efficiency. By carefully evaluating these aspects, you can choose an automatic pallet wrapper that enhances your operations and drives productivity.

Revolutionizing Warehouse Efficiency: The Science Behind Automatic Pallet Wrappers

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Automatic Film Cutter | Cuts the film automatically to prevent waste. | Improves efficiency and reduces material costs. | Ensure compatibility with the film type used. |

| Turntable Speed | Adjustable speed settings for rotating pallets. | Allows for customization based on load weight. | Higher speeds may affect stability with heavier loads. |

| Safety Features | Includes emergency stop buttons and protective barriers. | Increases worker safety and prevents accidents. | Regular maintenance is needed to ensure functionality. |

| Power Supply Options | Available in both electric and pneumatic models. | Flexibility to fit different warehouse environments. | Consider your warehouse’s power capacity and requirements. |

| Size Compatibility | Able to accommodate various pallet sizes. | Versatility in handling diverse products. | Verify size specifications before purchase. |

Implementing Automatic Pallet Wrappers: Best Practices for Integration

Implementing automatic pallet wrappers in warehouse operations can significantly enhance efficiency and productivity. According to a report by the Material Handling Industry of America (MHIA), companies that use automated solutions can increase their packing rates by up to 25%, transforming the speed and accuracy of pallet handling. To successfully integrate these systems, one must consider several best practices.

First, conducting a thorough analysis of the warehouse layout and workflow is essential. This helps in determining the optimal placement of the automatic wrappers to streamline operations and reduce handling time.

Another key aspect of successful integration is training staff effectively. A study by the Warehouse Education and Research Council (WERC) revealed that organizations investing in employee training on new technologies experience 30% fewer implementation challenges. This ensures that workers are adept at utilizing the wrappers while maintaining safety protocols.

Additionally, choosing the right type of automatic wrapper—whether rotary, orbital, or stretch film—based on the specific needs of the products being handled can further improve operational efficiency. By following these best practices, warehouses can maximize the benefits of automatic pallet wrappers and drive significant gains in productivity.

Measuring Efficiency Gains: KPIs to Track After Automation

In the modern warehouse environment, automation has transformed the way goods are handled, and automatic pallet wrappers are at the forefront of this revolution. To measure the efficiency gains from implementing this technology, it's crucial to set and track key performance indicators (KPIs). Some essential KPIs include wrapping cycle time, material costs, and labor savings. By quantifying these metrics, warehouses can assess the return on investment (ROI) for automation and continuously refine their processes.

Tips for success: Regularly monitor the wrapping cycle time to identify bottlenecks and make necessary adjustments. This can help streamline operations and reduce downtime. Additionally, consider tracking the cost of consumables, such as stretch film, to ensure that you are maximizing efficiency without compromising quality.

Another important KPI is the consistency of wrapped loads. This can affect the quality of shipping and storage, leading to fewer damages and returns. Implementing a quality check post-wrapping can greatly enhance your overall effectiveness.

Tips for success: Conduct periodic assessments to ensure that the automatic pallet wrappers are functioning optimally and producing consistent results. Training staff on handling and operating these machines will further maximize efficiency gains in your warehouse operations.

Revolutionizing Warehouse Efficiency: Measuring Efficiency Gains Post-Automation

Related Posts

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

Optimizing Case Packing Efficiency: Insights from Recent Industry Reports and Best Practices

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems