BLOG

Optimizing Case Packing Efficiency: Insights from Recent Industry Reports and Best Practices

In today's competitive landscape, optimizing case packing efficiency is more critical than ever for businesses seeking to reduce costs and improve their operational processes. As companies strive to streamline their supply chains, the focus on effective case packing strategies has gained momentum, driven by the need to maximize space utilization, minimize product damage, and enhance overall productivity.

Recent industry reports reveal valuable insights and best practices that can guide organizations in refining their case packing techniques. By understanding the importance of tailored packaging solutions and implementing advanced technologies, companies can not only improve their case packing processes but also achieve significant financial benefits.

This article aims to provide a comprehensive overview of how to enhance case packing efficiency, drawing upon the latest trends and expert recommendations to help businesses maintain a competitive edge in the market.

In today's competitive landscape, optimizing case packing efficiency is more critical than ever for businesses seeking to reduce costs and improve their operational processes. As companies strive to streamline their supply chains, the focus on effective case packing strategies has gained momentum, driven by the need to maximize space utilization, minimize product damage, and enhance overall productivity.

Recent industry reports reveal valuable insights and best practices that can guide organizations in refining their case packing techniques. By understanding the importance of tailored packaging solutions and implementing advanced technologies, companies can not only improve their case packing processes but also achieve significant financial benefits.

This article aims to provide a comprehensive overview of how to enhance case packing efficiency, drawing upon the latest trends and expert recommendations to help businesses maintain a competitive edge in the market.

Understanding the Importance of Case Packing Efficiency in Modern Logistics

In modern logistics, the efficiency of case packing plays a critical role in optimizing the overall supply chain. With the increasing demand for faster delivery and reduced operational costs, companies are recognizing that effective case packing can significantly enhance their logistics performance. By maximizing the space within shipping containers and minimizing wasted volume, businesses can not only lower shipping costs but also improve inventory management. This efficiency directly correlates with a company's ability to respond to market demands swiftly.

Furthermore, understanding the implications of case packing efficiency extends beyond mere cost savings. It has a profound impact on sustainability practices within the industry. Efficient packing reduces the number of containers needed for transport, leading to lower carbon emissions and decreased environmental impact. As consumers increasingly prioritize eco-friendly practices, companies that implement best practices in case packing can enhance their brand reputation and customer loyalty. Thus, investing in case packing strategies is not just a logistical necessity; it's also a commitment to sustainable growth in an ever-evolving marketplace.

Innovative Technologies Driving Case Packing Optimization Strategies

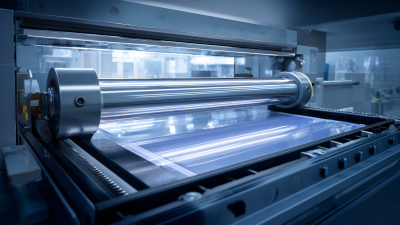

In recent years, the case packing industry has undergone significant transformations driven by innovative technologies. As companies seek to optimize their packing efficiency, advancements in artificial intelligence, the Internet of Things (IoT), and blockchain are becoming pivotal. These technologies facilitate real-time data transmission, allowing for improved decision-making and automation in packing processes. For example, AI algorithms can analyze packing patterns and suggest optimal configurations, thereby reducing wasted space and materials.

Moreover, leading brands are increasingly focusing on sustainability through their packaging strategies. The integration of intelligent solutions not only enhances operational efficiency but also promotes the use of recyclable materials and minimizes plastic waste. Companies are exploring generative AI tools to discover new packaging options that meet both performance standards and environmental goals. This intersection of technology and sustainability is redefining best practices in case packing, aligning business operations with the growing demand for eco-friendly practices. As such, organizations are well-positioned to drive innovation while meeting customer expectations in an evolving marketplace.

Leveraging Data Analytics for Enhanced Packing Performance

In the realm of case packing efficiency, leveraging data analytics emerges as a pivotal strategy for enhancing packing performance. The global market for lifecycle assessment (LCA) software is projected to grow significantly, from $261.8 million in 2025 to $695.3 million by 2032, reflecting a robust compound annual growth rate of 15.0%. This remarkable growth highlights the increasing reliance on advanced analytical tools to streamline operations and optimize decision-making processes within the packaging industry.

Innovative solutions, such as RAPIDS and Ray, utilize GPU acceleration to expedite data analysis, offering insights that were previously unattainable through traditional methods. Companies like DS Smith are at the forefront of this technological advancement, employing machine learning-based solutions on cloud platforms to enhance procurement spend insights. By harnessing these data-driven approaches, manufacturers can identify efficiencies, reduce costs, and gain a competitive edge in the evolving market landscape. This strategic integration of analytics not only fosters operational excellence but also supports sustainability within the packaging sector.

Benchmarking Best Practices from Industry Leaders in Case Packing

In the ever-evolving landscape of logistics and supply chain management, case packing efficiency has emerged as a key determinant of operational success. Industry leaders are continuously benchmarking their practices to cultivate more streamlined processes. By examining insights from recent reports, organizations can identify innovative strategies that enhance their packing workflows, reduce waste, and improve overall productivity.

Tips for Optimizing Case Packing:

First, assessing the layout of packing stations can facilitate smoother workflows. Ensuring that materials are conveniently housed can reduce unnecessary movements and speed up the packing process. Secondly, leveraging automation technologies, such as robotic packers, not only accelerates the packing rates but also minimizes human error, leading to more consistent outcomes. Finally, regular training sessions for staff on best practices encourage adherence to optimized protocols, fostering a culture of efficiency throughout the organization.

Leaders in the industry emphasize the importance of using data analytics to monitor case packing metrics. By identifying key performance indicators, companies can make informed decisions and set realistic targets for improvement. Continuous feedback loops and benchmarks allow organizations to adapt their strategies over time, maintaining a competitive edge in a rapidly changing market.

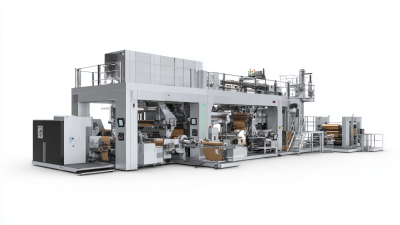

Evaluating the Impact of Automation on Packing Processes and Costs

Recent industry reports have been highlighting the significant influence of automation on packing processes and costs, particularly as companies seek to enhance packing efficiency. The automation of packing systems not only streamlines operations but also reduces labor costs and minimizes errors. With the global lifecycle assessment (LCA) software market anticipated to grow from $261.8 million in 2025 to $695.3 million by 2032, at a compound annual growth rate of 15.0%, companies are increasingly adopting automated solutions to optimize their packing processes. This trend reflects a broader move towards automation across various sectors, which is reshaping traditional packing methods.

Furthermore, as the pharmaceutical industry evolves, the demand for blister packaging machines is also experiencing growth. The blister packaging machine market, valued at $520 million in 2022, is projected to reach $840 million by 2030, showcasing a compound annual growth rate of 7.3% between 2024 and 2030. Automation plays a crucial role in this growth, enabling faster and more reliable production lines that meet the increasing standards for efficiency and safety in the pharmaceutical sector. As businesses continue to innovate and invest in automation technologies, the packaging landscape is set to transform significantly, offering new opportunities for efficiency and cost reduction.

Related Posts

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions