BLOG

2025 How to Optimize Your Packaging Automation Solutions for Maximum Efficiency

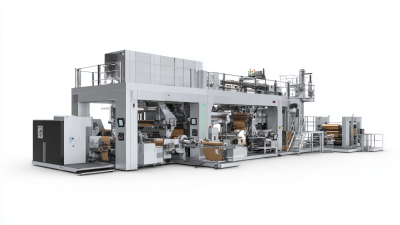

In the rapidly evolving landscape of manufacturing and logistics, optimizing packaging automation solutions has become a critical priority for companies aiming to achieve peak operational efficiency. As we approach 2025, advancements in technology and an increasing emphasis on sustainability are driving the need for sophisticated packaging strategies that not only streamline processes but also enhance productivity. In this context, businesses must explore innovative approaches that integrate cutting-edge automation technologies to meet consumer demands and reduce operational costs.

Effective packaging automation solutions encompass a wide array of techniques and tools designed to improve speed, accuracy, and flexibility in packaging operations. Companies must consider their unique requirements and the latest industry trends when selecting the right automation systems. By doing so, organizations can significantly reduce manual labor, minimize errors, and ultimately improve their overall supply chain management. As we delve deeper into best practices and emerging technologies within this domain, it is crucial to understand how these solutions can be tailored to harness maximum efficiency and adapt to future challenges in the packaging sector.

Understanding Current Trends in Packaging Automation for 2025 Efficiency Gains

The packaging machinery industry is set to experience significant growth as the demand for automation, efficiency, and sustainability in packaging processes escalates. By 2024, the sustainable packaging equipment market is projected to exceed $157.6 billion, driven primarily by the rise of e-commerce and advancements in packaging technologies. From filling and sealing to labeling, innovations in machinery will play a crucial role in optimizing packaging solutions across various sectors, including food, pharmaceuticals, and consumer goods.

Additionally, the logistics sector is embracing transformative trends to further enhance efficiency in packaging automation. Key innovations such as AI-driven warehousing, sustainable solutions, and last-mile technology upgrades are expected to reshape supply chains significantly. Companies are leveraging smart forecasting and green delivery methods to streamline operations, which not only reduces costs but also contributes to environmental goals. As the industry prepares for 2025, understanding these trends will be essential for maximizing efficiency in packaging automation solutions.

Evaluating Packaging Machinery: Key Metrics for Enhanced Performance in 2025

In 2025, evaluating packaging machinery's performance is crucial for enhancing efficiency. Key metrics include throughput, downtime, and quality metrics, which should align with advancements in machine learning and automation technologies. For instance, recent studies highlight the significant impact of integrating graph neural networks in assessing the aesthetic quality of packaging designs. This method not only improves visual appeal but also aids in predictive maintenance of machinery, ensuring seamless operations.

Tips: To optimize your packaging automation, focus on real-time data analytics. Implementing performance metrics such as the Net Promoter Score can provide insights into customer satisfaction with packaging, guiding improvements. Additionally, adopting sustainable packaging solutions can address the barriers faced in 2025, driving both environmental responsibility and customer preference.

As companies seek to enhance their packaging automation strategies, they should regularly assess machine learning models used in predictive performance evaluations. Organizations should also prioritize metrics that evaluate employee performance related to packaging operations, ensuring that staff are equipped to leverage new technologies effectively. By establishing a clear framework for evaluating these metrics, companies can significantly improve their packaging processes and overall efficiency.

Integrating AI and IoT Technologies to Streamline Packaging Processes by 2025

As packaging automation continues to evolve, the integration of Artificial Intelligence (AI) and Internet of Things (IoT) technologies is crucial for enhancing efficiency and effectiveness in packaging processes. By 2025, the synergy between AI and IoT will enable real-time data collection and analysis, allowing manufacturers to identify bottlenecks and implement immediate corrective actions. AI algorithms can predict operational issues before they arise, ensuring that machinery operates at peak performance while minimizing downtime.

Moreover, IoT devices will facilitate seamless communication across packaging systems, enabling enhanced visibility and control over the entire supply chain. Sensors embedded in packaging equipment can monitor performance metrics and provide actionable insights on material usage and equipment health. This data-driven approach not only streamlines packaging processes but also supports sustainability efforts by optimizing resource consumption. By harnessing the power of AI and IoT, businesses can create a future-proof packaging automation solution that not only meets rising consumer demands but also adapts to the ever-changing market landscape.

2025 How to Optimize Your Packaging Automation Solutions for Maximum Efficiency

| Dimension | 2023 Value | 2025 Projected Value | AI & IoT Impact |

|---|---|---|---|

| Speed of Packaging (Units/Hour) | 150 | 220 | +46.7% |

| Error Rate (%) | 3.5 | 1.2 | -65.7% |

| Labor Costs per Unit | $0.75 | $0.50 | -33.3% |

| Downtime (Hours/Month) | 10 | 4 | -60% |

| Waste Reduction (%) | 20 | 30 | +50% |

Sustainability in Packaging: Balancing Efficiency and Environmental Impact for 2025

As the world shifts towards a more sustainable future, the packaging industry faces the dual challenge of enhancing efficiency while minimizing environmental impact. In 2025, companies must prioritize the integration of sustainable materials into their packaging solutions. This involves selecting biodegradable or recyclable materials that not only reduce waste but also appeal to eco-conscious consumers. By investing in research and development, businesses can create innovative packaging that meets both functionality and sustainability standards, ensuring they stay competitive in a rapidly evolving market.

Moreover, optimizing packaging automation solutions plays a crucial role in achieving these sustainability goals. Automation can streamline processes, reduce material waste, and enhance production speed without compromising the quality of the packaging. Implementing advanced technologies like AI and machine learning can further refine packaging operations, allowing businesses to adapt swiftly to changing consumer demands while maintaining a low carbon footprint. Ultimately, the balance between efficiency and environmental responsibility will define successful packaging strategies in 2025 and beyond.

Sustainability in Packaging: Balancing Efficiency and Environmental Impact for 2025

Training and Upskilling Workforce for Optimal Use of Automated Packaging Solutions in 2025

In 2025, the landscape of packaging automation is evolving rapidly, necessitating a focus on training and upskilling the workforce to leverage these advanced technologies effectively. A recent report from Smithers Pira indicates that the global market for automated packaging solutions is projected to grow by 13.4% annually, reaching over $70 billion by 2025. This growth highlights the critical need for companies to invest in comprehensive training programs to maximize the benefits of these automated systems.

To achieve optimal use of automated packaging solutions, organizations must prioritize ongoing education that fosters familiarity with new equipment and software. According to a study by McKinsey, businesses that invest in continuous employee development can see productivity improvements of up to 30%. By equipping their teams with the necessary skills, companies can ensure that their workforce is not only capable of operating advanced technologies but also of troubleshooting issues swiftly, thus minimizing downtime and enhancing overall efficiency. Emphasizing a culture of learning within the workforce will be essential in keeping pace with the evolving demands of the packaging industry.

Related Posts

-

2025 Top 5 Innovative Packaging Equipment Trends Transforming the Industry

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Revolutionizing Efficiency in Manufacturing with an Automated Packaging Line for Sustainable Growth

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices