BLOG

How to Choose the Best Pallet Shrink Wrap Machine for Your Business Needs

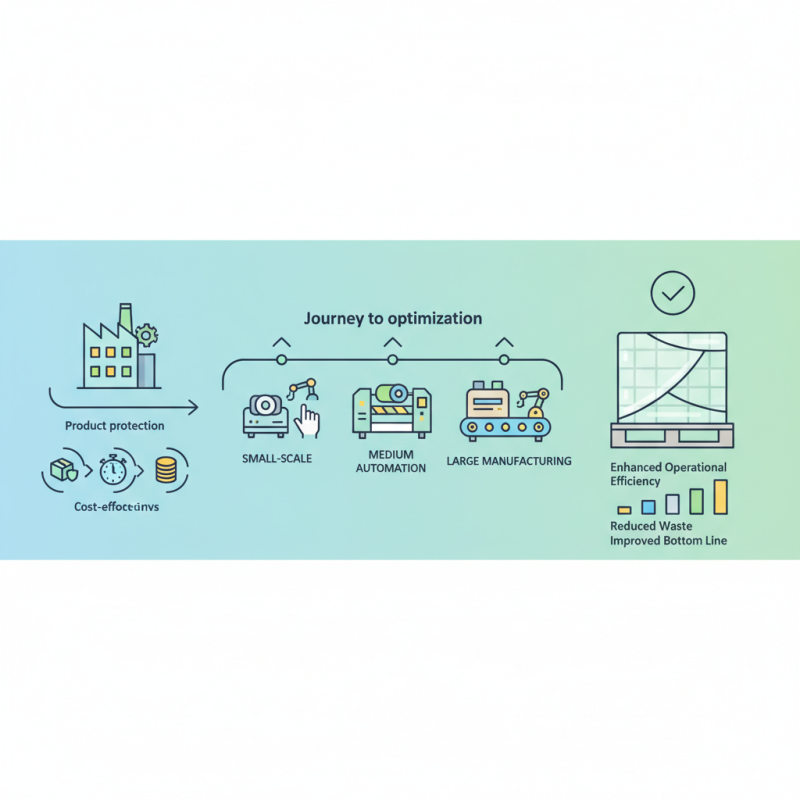

When it comes to optimizing shipping efficiency and product protection, the choice of a pallet shrink wrap machine is paramount for any business. Steven Johnson, an industry expert and logistics consultant, emphasizes, "Investing in the right pallet shrink wrap machine can significantly enhance your operational efficiency and reduce waste." This underscores the importance of selecting a machine that aligns with specific business requirements.

The landscape of pallet shrink wrap machines is diverse, with various features catering to different needs, from small-scale operations to large manufacturing facilities. Each machine comes with its unique specifications, and understanding these can be a game-changer in streamlining packaging processes. By considering factors such as machine size, speed, and automation level, businesses can make informed decisions that contribute to their overall productivity.

In a competitive market, having the right equipment not only protects products during transportation but also impacts the bottom line. Therefore, taking the time to evaluate your packaging needs and understanding the capabilities of available machines is essential. A well-chosen pallet shrink wrap machine can transform your packaging operations, enhancing both efficiency and cost-effectiveness in the long run.

Factors to Consider When Selecting a Pallet Shrink Wrap Machine

When selecting a pallet shrink wrap machine, several factors play a crucial role in ensuring you choose the best fit for your business needs. First, consider the machine’s capacity and speed. If your business involves high-volume packaging, a machine with a faster wrapping speed will increase efficiency and reduce downtime. Look into the size and type of the pallets you commonly use to ensure the machine can accommodate your products.

Additionally, think about the flexibility and features of the shrink wrap machine. Some machines offer adjustable settings that cater to different sizes and types of shrink wrap materials, making them versatile for various packaging tasks. Investing in a machine with automated features, such as auto-feed, can significantly enhance productivity and reduce labor costs by minimizing manual intervention.

**Tips**: Always evaluate the machine's ease of use and maintenance. A user-friendly interface will allow your team to train quickly, while a machine that requires minimal maintenance will save your business time and money in the long run. Don’t forget to check the warranty and customer support options available, as these can provide peace of mind and assistance when needed.

Types of Pallet Shrink Wrap Machines Available on the Market

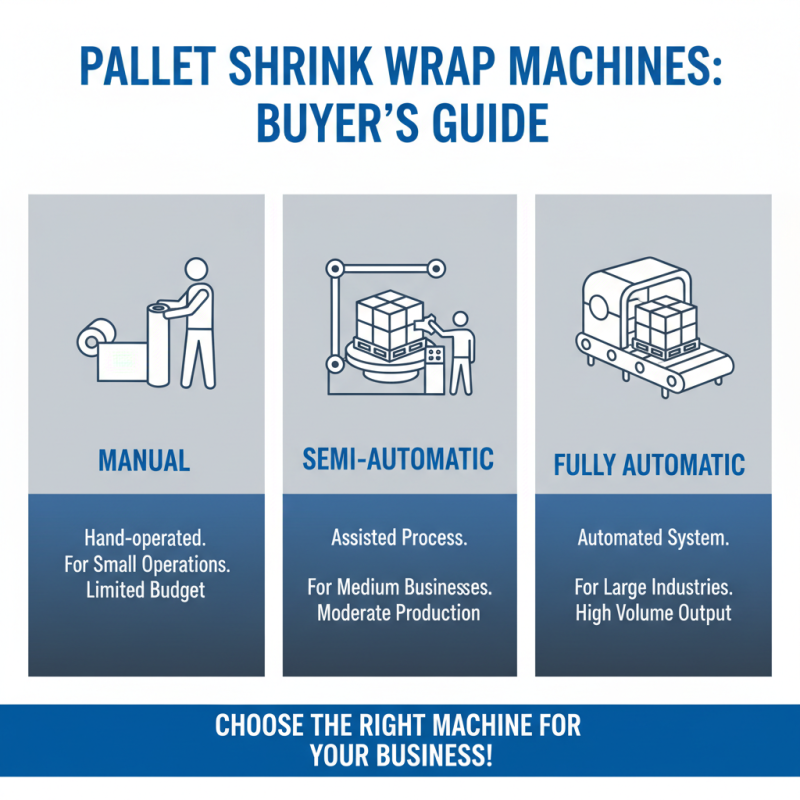

When selecting the right pallet shrink wrap machine for your business, it's essential to understand the different types available on the market. The three most common types are manual, semi-automatic, and fully automatic machines. Manual machines require operators to wrap pallets by hand, making them ideal for smaller operations with limited budgets. Semi-automatic machines simplify the process by handling the shrink wrapping while still requiring some manual intervention, making them suitable for medium-sized businesses with moderate production needs.

Fully automatic pallet shrink wrap machines offer the highest efficiency, automatically wrapping and sealing pallets without operator involvement. These machines are perfect for large-scale operations where speed and consistency are critical. Additionally, they can be integrated into conveyor systems, enhancing productivity and reducing labor costs.

**Tips:** When choosing a shrink wrap machine, consider your production volume and budget. Assess the size and weight of the pallets you will be wrapping, as different machines have varying capacities. Always prioritize machines that offer adjustable settings for different pallet sizes to maximize versatility.

Evaluating the Efficiency and Speed of Shrink Wrap Machines

When choosing a pallet shrink wrap machine, evaluating its efficiency and speed is crucial to align with your business needs. Efficiency in shrink wrap machines is often determined by their ability to quickly wrap products while minimizing material waste. Look for features such as adjustable speed settings, which can allow operators to tailor the wrapping process to suit different product sizes and configurations. A machine that offers reliability and consistent performance will not only improve productivity but also reduce downtime caused by frequent adjustments or maintenance needs.

Speed is another key factor; a machine that can handle a high throughput will significantly enhance your workflow. Consider the shrink wrap machine’s cycle times and how they match your packaging volume requirements. Additionally, machines equipped with advanced technology, such as infrared heaters for faster heat application, can further increase wrapping speed without compromising quality. Evaluating both efficiency and speed ensures that you invest in a machine that supports your operational goals, enhances your output, and ultimately contributes to your bottom line.

How to Choose the Best Pallet Shrink Wrap Machine for Your Business Needs

| Feature | Description | Efficiency Rating | Speed (Units per Hour) | Cost (USD) |

|---|---|---|---|---|

| Automatic Shrink Wrapper | Fully automated wrapping system for high volume. | 95% | 150-200 | $12,000 |

| Semi-Automatic Shrink Wrapper | Operated manually with semi-automatic features. | 85% | 80-120 | $6,500 |

| Manual Shrink Wrapper | Requires manual wrapping and sealing process. | 70% | 30-50 | $2,000 |

| Low-Profile Wrapper | Designed for low pallets or special applications. | 80% | 60-100 | $5,000 |

Understanding the Cost Implications of Different Models

When evaluating different pallet shrink wrap machines for your business, understanding the cost implications associated with each model is crucial. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), the initial investment for entry-level machines can range from $5,000 to $15,000, while high-capacity, automated models may cost upwards of $50,000. This significant price variance underscores the importance of conducting a thorough needs assessment to determine which machine aligns best with your production volume and operational budget.

In addition to the upfront costs, it is essential to factor ongoing operational expenses such as maintenance and film costs. The International Journal of Packaging Technology highlights that businesses should an average of $0.02 to $0.05 per foot for shrink wrap film, depending on the quality and thickness required for the specific applications. Furthermore, advanced models with higher efficiency ratings can yield better long-term savings by reducing film consumption and energy costs. Therefore, while the initial purchase price may seem high, the total cost of ownership should include these operational efficiencies and savings for a more accurate financial forecast.

Cost Comparison of Different Pallet Shrink Wrap Machines

Maintenance and Support Considerations for Shrink Wrap Machines

When investing in a pallet shrink wrap machine, maintenance and support are critical factors that can significantly impact your business operations. Regular maintenance ensures that your machine operates efficiently, reducing downtime and prolonging its lifespan. According to industry reports, the average cost of equipment downtime can exceed $260,000 per hour for manufacturing environments. Thus, establishing a proactive maintenance schedule—ideally tailored by the machine's manufacturer or a professional service provider—can mitigate these costs and maximize productivity.

Support considerations also play a vital role in your choice of shrink wrap machines. Ensuring you have access to reliable customer support can make a substantial difference in resolving issues quickly. A survey conducted by the Association for Packaging and Processing Technologies found that 70% of businesses suffered from operational disruptions due to inadequate support services. Therefore, it's essential to partner with suppliers who offer comprehensive support packages, including training, immediate troubleshooting assistance, and access to spare parts. By prioritizing maintenance and support, businesses can optimize their usage of shrink wrap machines while safeguarding their investment for the long term.

Related Posts

-

Top 10 Benefits of Using a Pallet Spinner in Your Warehouse Operations

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

Why You Need a Carton Erector for Streamlined Packaging Operations

-

2025 Top 5 Innovative Packaging Equipment Trends Transforming the Industry

-

2025 How to Optimize Your Packaging Automation Solutions for Maximum Efficiency