BLOG

How to Choose the Right Palletizer Machine for Your Warehouse Needs

In the rapidly evolving world of warehousing and logistics, selecting the right palletizer machine is a critical decision that can significantly impact efficiency and productivity. According to industry expert Dr. Emily Timmons, a renowned logistics consultant, “Choosing the right palletizer machine is not just about the initial cost; it’s about understanding the long-term benefits it brings to your operations.” This insight underscores the importance of evaluating various factors before making a purchase.

When it comes to palletizer machines, the options are vast and varied, catering to different warehouse needs. From high-speed automation to more compact designs suitable for space-constrained environments, the right choice hinges on a thorough analysis of your specific operational requirements. Factors such as product type, throughput, and available floor space must be carefully considered to ensure that the selected palletizer aligns with both current demands and future growth.

In this guide, we will explore essential criteria for selecting an optimal palletizer machine, shedding light on key considerations that will help you make an informed decision for your warehouse operations. By aligning your choice with strategic goals, you can enhance efficiency, reduce costs, and ultimately drive greater success in your logistics processes.

Understanding the Functionality of Palletizer Machines

Palletizer machines play a crucial role in the efficiency of warehousing by automating the stacking and arranging of products onto pallets. Understanding their functionality is essential for optimizing operations and simplifying the workflow within your facility. These machines can significantly reduce labor costs and minimize errors associated with manual stacking, leading to faster processing times and increased productivity.

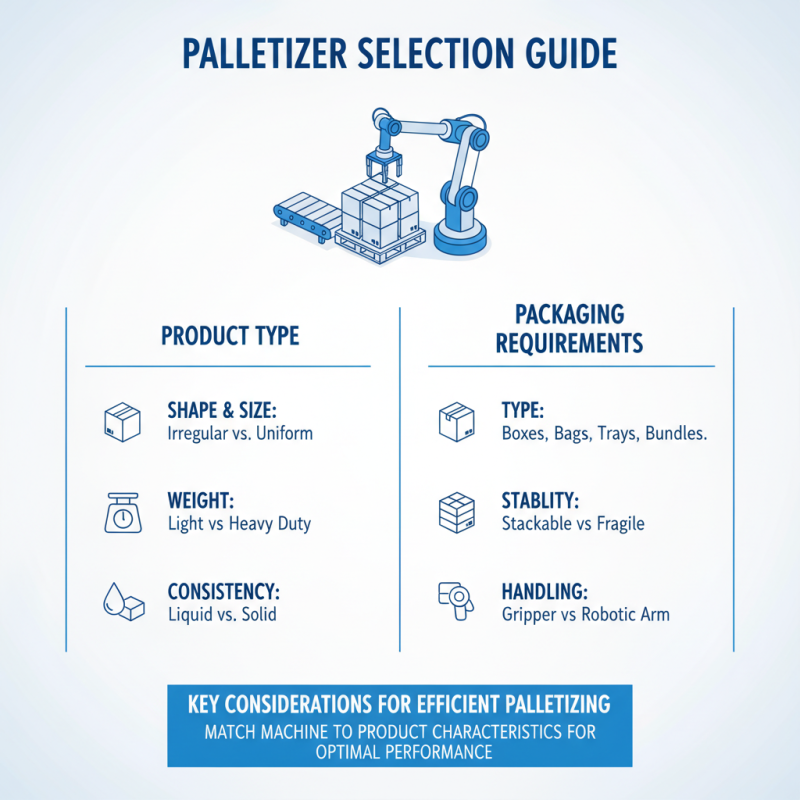

When selecting a palletizer, it is important to consider the types of products you will be handling. Regularly assess the size, weight, and packaging of your items, as different palletizers are designed to accommodate diverse specifications. Choose a model that offers flexibility to adapt to various product ranges while ensuring consistent stacking quality.

Tips:

- Evaluate the throughput requirements of your warehouse to ensure the machine can handle peak production times.

- Investigate the ease of operation and maintenance for chosen machines, as this can impact long-term performance and staff training.

- Consider the available floor space and overall layout of your warehouse before making a decision, as this will help determine the type of palletizer that can be efficiently integrated into your existing systems.

Evaluating Your Warehouse Space and Configuration Needs

Evaluating your warehouse space and configuration needs is a critical first step in choosing the right palletizer machine. Start by measuring the dimensions of your available space, considering both the floor area and vertical height. This will help you determine the footprint of the palletizer and any auxiliary equipment that may be necessary for its operation. Additionally, assess the layout of your warehouse:

Is it designed for linear flow, or do you have to navigate around obstacles? A clear understanding of your warehouse layout will inform whether a conventional palletizer or a robotic system is more suitable for your operation.

In addition to physical space, consider how often your production lines fluctuate in volume. A flexible palletizer might be necessary if your output varies significantly throughout the day or week. Factor in the accessibility of the machine; you’ll want to ensure that operators can easily reach the machine for maintenance and troubleshooting without disrupting workflow. Finally, take into account any future growth or changes in your warehousing needs. Investing in a palletizer with scalable options can help accommodate potential expansions without requiring a complete system overhaul. This forward-thinking approach will ensure that your chosen palletizer aligns well with your evolving warehouse demands.

Identifying Product Types and Packaging Requirements

When selecting a palletizer machine for your warehouse, it's essential to examine the types of products you handle and their packaging requirements. Different products often have unique shapes, sizes, and weights, which can significantly influence the performance and efficiency of a palletizer. For instance, bulkier items may necessitate a robust design to withstand the load, while smaller or oddly shaped products might require a more flexible system to ensure proper alignment and placement on the pallets.

Packaging materials also play a crucial role in determining the suitable palletizer machine. Consider whether your products are packaged in cardboard boxes, shrink-wrapped, or bagged, as each type may require different handling mechanisms. Moreover, varying packaging dimensions can affect the entire palletizing process, making it vital to choose a machine that can accommodate your specific packaging configurations. Conducting a thorough assessment of your product types and packaging requirements will help guide your decision, ensuring that the palletizer machine you select meets both efficiency and productivity standards tailored to your warehouse needs.

Assessing Automation Levels and Throughput Capabilities

When selecting a palletizer machine for your warehouse, understanding the automation levels and throughput capabilities is crucial. Automation levels can vary significantly, from fully automated systems that require minimal human intervention to semi-automated options that still rely on some manual processes. Companies should assess the volume of products that need to be handled and the speed at which they must operate. A fully automated palletizer may be ideal for high-volume operations, where the investment in advanced robotics and controls can lead to significant labor savings and increased efficiency.

Throughput capabilities also play a major role in choosing the right palletizer. It’s important to evaluate how many pallets per hour the machine can handle, as this will impact the overall productivity of the warehouse. High-throughput systems should be matched with the expected production rates to ensure that there are no bottlenecks in the packaging line. Additionally, consider scalability; as demand increases, the palletizer should be able to adapt to changing volumes without requiring a complete replacement. Balancing these factors will help in selecting a machine that aligns with your operational needs and facilitates seamless warehouse management.

How to Choose the Right Palletizer Machine for Your Warehouse Needs - Assessing Automation Levels and Throughput Capabilities

| Palletizer Type | Automation Level | Throughput (Units/hour) | Footprint (sq ft) | Key Features |

|---|---|---|---|---|

| Robotic Palletizer | High | 600 | 20 | Flexibility, Versatile Gripper Options |

| Conventional Palletizer | Medium | 400 | 30 | Cost-effective, Simple Design |

| Automated Palletizer | High | 800 | 25 | Integration with Warehouse Management Systems |

| Semi-Automatic Palletizer | Low | 200 | 15 | Manual Intervention Required, Easy Setup |

| Layer Palletizer | Medium | 500 | 28 | Layering Capability, Robust Construction |

Budgeting for Initial Investment and Ongoing Maintenance Costs

Investing in a palletizer machine is a significant financial decision for any warehouse. Budgeting for both the initial investment and ongoing maintenance costs is crucial to ensure that you select the right equipment for your operational needs. Research indicates that the average price of palletizers can range between $25,000 to $150,000 depending on their specifications, capabilities, and automation levels. A well-planned budget should account not just for the purchase price, but also for installation, training, and the potential need for facility modifications.

Ongoing maintenance costs are another critical factor. It is estimated that annual maintenance can account for 10-15% of the initial investment, which can lead to thousands of dollars each year depending on your machine's complexity. Regular service intervals and upkeep are essential to avoid unplanned downtimes that can disrupt warehouse operations. Investing in a comprehensive maintenance plan can pay dividends in extending the lifespan of your equipment and ensuring optimal performance.

Tips: When budgeting, consider setting aside a contingency fund of 15-20% of your total initial investment. This can serve as a buffer for unexpected costs related to repairs or parts replacement. Additionally, prioritize selecting machines with a strong track record for reliability and lower maintenance needs to minimize future expenditures.

Warehouse Palletizer Machine Costs Overview

Related Posts

-

Revolutionizing Efficiency in Manufacturing with an Automated Packaging Line for Sustainable Growth

-

2025 Guide to the Best Case Packer Manufacturers for Efficient Packaging Solutions

-

Optimizing Case Packing Efficiency: Insights from Recent Industry Reports and Best Practices

-

Top 10 Benefits of Using a Pallet Spinner in Your Warehouse Operations

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

How to Choose the Best Case Packaging for Your Products Efficiently