BLOG

What is a Case Packer and How It Transforms Your Packaging Process

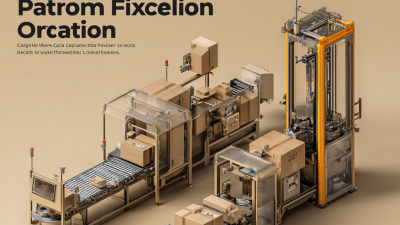

In the ever-evolving landscape of manufacturing and logistics, efficiency and precision are paramount. As companies strive to optimize their packaging processes, the case packer has emerged as a transformative solution. This innovative machine automates the packing of products into cases, significantly enhancing workflow while reducing labor costs. With the rise of e-commerce and consumer demands for faster delivery, the case packer plays a critical role in meeting these challenges, ensuring that products are securely packed and ready for distribution.

The integration of a case packer into a production line is not merely an upgrade; it is a strategic investment that can yield substantial dividends. By streamlining operations, minimizing human error, and maximizing space utilization, businesses can significantly improve their output and overall productivity. This introduction of technology into packaging processes exemplifies how automation fosters a more agile and responsive supply chain, which is increasingly vital in today’s market.

As we explore the "2025 Top 5" case packers, it becomes evident that these machines are not just tools; they represent a forward-thinking approach to packaging that aligns with the demands of modern commerce. Their capability to adapt to various products and packaging types further solidifies their importance in the current and future manufacturing environments. Discover how a case packer can revolutionize your operations and position your business for success in an increasingly competitive world.

Understanding the Role of a Case Packer in Modern Manufacturing

A case packer plays a pivotal role in modern manufacturing, serving as a critical component in the packaging line. This automated machine is designed to efficiently load products into cases, enhancing speed and accuracy compared to manual packing. The integration of case packers in production facilities helps to streamline operations, reduce labor costs, and minimize errors. By automating the packing process, manufacturers can meet high demand without sacrificing product quality or consistency.

In addition to improving efficiency, case packers also contribute to sustainability efforts within manufacturing. Many modern models are equipped with features that optimize packing patterns, reducing the amount of packaging material used and minimizing waste. Furthermore, with the ability to handle a wide variety of products, case packers support flexibility in production lines, allowing manufacturers to adapt quickly to changing market demands. As industries continue to embrace automation, case packers will undoubtedly play an essential role in transforming the packaging process, ensuring that products are not only delivered quickly but also responsibly.

Benefits of Integrating a Case Packer into Your Packaging Workflow

Integrating a case packer into your packaging workflow can significantly enhance both efficiency and accuracy. One of the primary benefits is the speed at which products can be packed. Case packers automate the process of filling cases with products, thereby reducing the manual labor required and minimizing human error. This not only speeds up the packaging line but also ensures a consistent packing quality, which is essential for maintaining brand integrity.

Furthermore, case packers contribute to better space utilization within a facility. By automating the packing process, companies can decrease the footprint required for manual packing stations, freeing up space for other essential operations. This increased efficiency in packaging can lead to higher throughput and can support scalability as demand grows. Additionally, the integration of case packers can result in reduced labor costs over time, making it a financially advantageous decision for businesses looking to streamline their packaging processes.

Key Features to Look for in a High-Performance Case Packer

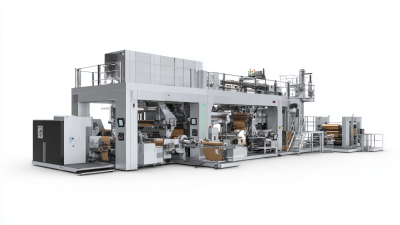

When selecting a high-performance case packer, there are several key features to consider that can significantly enhance your packaging efficiency. One crucial aspect is automation capabilities. According to a report by PMMI, the Association for Packaging and Processing Technologies, automated packaging solutions can increase production speeds by up to 30% while reducing labor costs by approximately 20%. This allows businesses to allocate resources more effectively and respond faster to market demands.

Another important feature is adaptability. A versatile case packer can handle various product sizes and types without the need for extensive reconfiguration. This flexibility is vital in today’s fast-paced manufacturing environment, where product diversity is on the rise. A recent study from BCG reveals that manufacturers with adaptable packaging systems experience a 25% increase in operational efficiency. Furthermore, ease of integration with existing production lines can streamline the overall process, minimizing downtime and boosting productivity.

Lastly, the ergonomic design of a case packer should not be overlooked. Ergonomic considerations not only contribute to worker safety but also enhance productivity. According to a research paper by the Occupational Safety and Health Administration (OSHA), ergonomic improvements can lead to a 15-25% reduction in workplace injuries, which ultimately translates to lower operational costs and a healthier workforce. Therefore, choosing a case packer with these key features can greatly transform your packaging process for the better.

What is a Case Packer and How It Transforms Your Packaging Process

| Feature | Description | Importance | Impact on Process |

|---|---|---|---|

| Speed | The rate at which cases are packed per minute. | High, as it directly affects throughput. | Increases efficiency and reduces labor costs. |

| Flexibility | Ability to handle various case sizes and products. | Moderate, necessary for diverse operations. | Allows for quick adjustments to production lines. |

| Automation | Level of automated processes in operation. | High, enhances labor savings. | Reduces human error and speeds up packing. |

| Integration | Compatibility with existing machinery and systems. | Very Important for seamless operations. | Optimizes workflow and ensures data accuracy. |

| Durability | Construction quality and reliability of the machine. | Critical for long-term use. | Minimizes downtime due to repairs or replacements. |

Comparing Manual and Automated Case Packing Solutions

Automated case packing solutions are revolutionizing the packaging industry by offering significant advantages over traditional manual methods. Recent reports indicate that the case packing machines market is projected to reach USD 2.0 billion by 2035, with a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2025 to 2035. This growth reflects the industry's increasing reliance on automation to enhance efficiency and reduce labor costs.

A key development in this area is the introduction of collaborative robots (cobots) designed for case packing. These systems can pack cases up to 70% faster than manual loading processes, thereby streamlining operations and improving productivity. This not only allows companies to keep pace with rising demand but also minimises the risk of manual handling errors. As industries continue to adopt automated solutions, the contrast between manual and automated case packing has never been more pronounced, making the transition to automated systems an essential consideration for businesses aiming to optimize their packaging processes.

Case Packer Technology: Innovations Shaping the Future of Packaging

In the ever-evolving landscape of packaging technology, case packers have emerged as key players that significantly enhance operational efficiency. These automated systems streamline the process of packing products into cases, drastically reducing labor costs and minimizing the likelihood of errors. Innovations in case packing technology focus on flexibility, fast changeover times, and advanced robotics, allowing businesses to adapt to varying production needs while maintaining high speed and accuracy.

Tips: When selecting a case packer, consider the range of products you plan to package. A machine that can handle multiple sizes and shapes will offer greater versatility. Additionally, look for models equipped with smart technology features, such as predictive maintenance alerts, which can prevent downtime and optimize productivity.

The future of packaging is also shaped by advancements in sustainability. Case packers are increasingly being designed to reduce material waste and incorporate eco-friendly materials. Smart sensors and data analytics provide real-time insights, allowing companies to monitor and adjust their packaging processes for maximum efficiency.

Tips: Before investing in a case packer, assess your company's sustainability goals. Choose machines that not only meet your current needs but also align with your environmental objectives, ensuring long-term benefits for both your business and the planet.

Related Posts

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping

-

Why You Need a Carton Erector for Streamlined Packaging Operations

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

What is Pallet Wrap? Understanding Its Uses and Benefits for Shipping

-

Revolutionizing Efficiency in Manufacturing with an Automated Packaging Line for Sustainable Growth

-

Top 10 Innovative Case Packaging Solutions Transforming the Industry in 2023