BLOG

10 Best Stretch Wrap Options for Packaging and Storage Solutions?

When it comes to packaging and storage solutions, stretch wrap is essential. This versatile material provides stability and protection for a variety of goods. Many businesses and individuals rely on stretch wrap for efficient organization and safe transportation.

Choosing the right stretch wrap can be overwhelming. There are numerous options available, each designed for specific needs. Some may find it challenging to determine the best type for their requirements. It's vital to consider factors like thickness, clarity, and stretchability before making a purchase.

Generally, the best stretch wrap serves multiple purposes. It can protect products from dust, moisture, and damage during transit. However, finding the perfect fit might require effort and may not always yield immediate results. Assessing your needs is a step that shouldn’t be overlooked. In this article, we will explore the top options available, showcasing the importance of selecting the right stretch wrap for your packaging endeavors.

Best Stretch Wrap Types for Efficient Packaging Solutions

Stretch wrap is essential for protecting goods during storage and transport. Understanding different types helps in choosing the right solution. There are several stretch wrap options available, each serving a unique purpose. Common types include hand stretch wrap and machine stretch wrap. Hand wraps are flexible and easy to use, ideal for smaller tasks. Machine wraps are suitable for larger operations and offer consistent tension.

Another important aspect is thickness. Thicker wraps provide better protection against punctures and tears. However, using thicker film may increase costs. Balancing protection and budget is crucial. Additionally, consider the wrap's stretchability. High stretchability allows for tighter loads, reducing the risk of shifting during transit.

Lastly, color options can also play a role. Colored wraps help with organization and identification. They can signal specific contents or indicate fragile items. However, some may prioritize clear wraps for visibility. Reflecting on these details can lead to better decision-making in selecting the right stretch wrap type. Each choice has pros and cons that require careful consideration.

Key Features to Look for in Stretch Wrap Materials

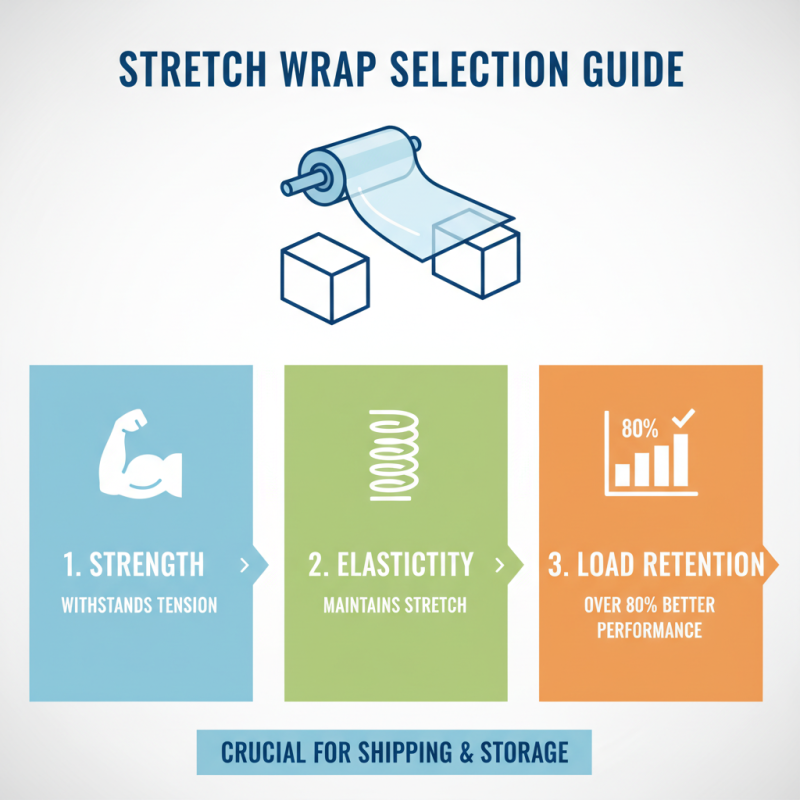

When selecting stretch wrap for packaging and storage, key features play a crucial role. Many choose materials for their strength and elasticity. A good stretch wrap should withstand tension while maintaining a constant level of stretch. Reports show that stretch wrap with a load retention of over 80% performs better in various environments. This resilience is vital, especially in shipping and long-term storage.

Another important factor is puncture resistance. High-quality stretch wrap should resist accidental tears or punctures during handling. An industry study noted that wraps with a thickness of 80-100 gauge provide a solid defense against damage. These thicker options are often preferred for heavier loads. Additionally, stretch wrap offers different options, such as pre-stretched or hand rolls, catering to varied applications.

Moreover, clarity is often overlooked. Clear wraps allow visibility, making it easier to identify contents without unwrapping. Some reports emphasize that clarity can enhance inventory management. Users may need to reflect: is clarity a priority for their specific needs? Evaluating these features ensures the right choice of stretch wrap, leading to better protection and efficiency in storage solutions.

Comparative Analysis of Stretch Wrap for Storage Uses

When it comes to storage, the right stretch wrap can make a significant difference. Various types cater to different needs. The thickness and clarity matter. For instance, thicker wraps often offer better protection. They shield against dust and moisture. Yet, they can be more challenging to handle.

A key factor is how well the wrap clings to itself. Some options may fail to stick properly, leading to frustrating spills or falls. Stretch wraps also differ in elasticity. A highly elastic wrap can provide a tight hold. But too much stretch can lead to tears. It's essential to balance these qualities based on your storage requirements.

Consider the transparency of the wrap as well. Clear options allow for easy identification of contents. But dark wraps can offer better UV protection. Choosing between them depends on whether visibility or protection is more crucial for your needs. Lastly, remember that the best option may not always be the most expensive. Sometimes, trial and error reveals surprising insights about your ideal choice.

Top Brands of Stretch Wrap Recommended by Professionals

When selecting stretch wrap for packaging and storage, professionals emphasize quality and reliability. Industry reports indicate that using the right stretch film can reduce product damage by up to 30%. This statistic highlights the importance of choosing materials wisely. Stretch wrap provides an excellent barrier against moisture and dust, ensuring product integrity during storage or transportation.

Many experts recommend certain features in stretch wraps. For instance, clarity is often crucial. A transparent wrap allows for quick identification of contents without unwrapping. Additionally, some findings indicate that thicker wraps can offer more protection, especially for heavy loads. However, there are missteps in using inadequate or flimsy wraps that lead to spoilage or damage. It's essential to match the stretch wrap with the specific needs of the item being packaged.

Not all stretch wraps perform equally. Some may become brittle under cold conditions. Others may not adhere well to irregular shapes. Feedback from professionals suggests that understanding the application can significantly influence the choice. A thorough assessment of the storage environment and products can help identify the best options. This often requires testing various wraps to see which holds up under real conditions. The learning process is crucial for enhancing packaging strategies.

Tips for Proper Application and Usage of Stretch Wrap

When using stretch wrap, proper application is essential for effective packaging. Begin by ensuring the surface is clean and dry. Dust and moisture can reduce adhesion. Always hold the roll tightly and apply consistent tension as you wrap. Uneven tension may lead to loose wrap, compromising the stability of the package.

Tips for proper usage include starting at one corner and working your way around. Use a figure-eight technique, which helps in locking items together. Make several layers if needed, especially for heavier items. A common mistake is wrapping too loosely. This can cause items to shift during transport. Focus on achieving a snug fit.

Lastly, avoid over-wrapping, as excessive layers can create waste and add unnecessary weight. It's important to balance protection with efficiency. Always consider the type of load and environmental conditions. Reflecting on your techniques can lead to better outcomes in the long run.

Comparison of Top 10 Stretch Wrap Options for Packaging

Related Posts

-

Top 10 Best Shrink Wrap Solutions for Packaging and Protection in 2023

-

How to Use Stretch Film for Effective Packaging and Protection?

-

What is Case Packing and How Does it Impact Your Shipping Efficiency

-

2025 How to Optimize Your Packaging Automation Solutions for Maximum Efficiency

-

10 Essential Tips for Choosing the Right Carton Packer for Your Business

-

Top 10 Benefits of Using a Pallet Spinner in Your Warehouse Operations