BLOG

Top 10 Best Shrink Wrap Solutions for Packaging and Protection in 2023

In the fast-evolving landscape of packaging solutions, shrink wrap has emerged as a vital player, offering unparalleled benefits in terms of protection, durability, and efficiency. According to market research, the global shrink wrap packaging market is projected to reach USD 30 billion by 2026, expanding at a compound annual growth rate (CAGR) of 5.2% from 2021. This growth is driven by the surge in e-commerce, where optimal packaging plays a crucial role in ensuring product safety during transit.

Shrink wrap not only enhances the aesthetic appeal of a product but also provides a barrier against moisture, dust, and other environmental factors that could compromise quality. The versatility of shrink wrap solutions extends across various industries, including food and beverage, pharmaceuticals, and consumer goods, where their application ensures that products remain intact and secure from the moment they leave the manufacturer until they reach the end consumer.

As we delve into the top 10 best shrink wrap solutions for packaging and protection in 2023, it is essential to understand how these innovations cater to diverse needs while adhering to sustainability practices. In a world where efficient and eco-friendly packaging is increasingly demanded, shrink wrap technology continues to evolve, ensuring that it remains at the forefront of packaging innovations.

Overview of Shrink Wrap Solutions and Their Importance in Packaging

Shrink wrap solutions play a vital role in the packaging industry, providing both protection and presentation for a wide array of products. As businesses and consumers become increasingly aware of the need for reliable packaging, shrink wrap has emerged as a preferred choice for its ability to conform tightly to product shapes, offering a tamper-proof seal that enhances security during transport and storage. The durability and moisture resistance of shrink wrap effectively preserve items, keeping them in pristine condition while clearly showcasing their features.

When considering shrink wrap solutions, it's essential to select the right type for your specific needs. One tip is to evaluate the temperature requirements of the shrink wrap you choose. Some materials require higher temperatures to achieve a snug fit, while others work effectively at lower heat. Additionally, considering the thickness of the wrap can impact both protection and aesthetics; a thicker wrap offers more durability but can be less visually appealing.

Another important factor is choosing the appropriate shrink wrap machinery. Investing in the right equipment—whether it’s a shrink tunnel, heat gun, or automatic sealer—can significantly boost efficiency and reduce manual labor. Always remember to conduct test runs to ensure a perfect seal and finish, as this can make all the difference in the overall quality of your packaging.

Types of Shrink Wrap Materials and Their Unique Properties

Shrink wrap materials come in various types, each with unique properties that make them suitable for specific packaging and protection needs. Among the most commonly used materials are PVC, polyethylene, and polypropylene. PVC shrink wrap is known for its excellent clarity and tight seal, making it an ideal choice for presenting products attractively while keeping them secure. It also possesses good puncture resistance and is particularly effective at wrapping irregularly shaped items.

Polyethylene, on the other hand, is favored for its durability and environmental resistance, making it suitable for outdoor applications. It provides strong protection against moisture and dust, making it a popular option for storing items long-term. Polypropylene is a versatile material that balances strength and flexibility, allowing it to be used for a variety of products, from food packaging to crafting. Each type of shrink wrap material brings its own set of benefits, enabling businesses to choose the best option based on their specific packaging requirements.

Factors to Consider When Choosing Shrink Wrap for Packaging Needs

When selecting shrink wrap for packaging needs, several factors play a crucial role in ensuring optimal protection and efficiency. First and foremost, consider the type of products being packaged. Different products may require varying levels of protection from moisture, dust, and physical damage. It’s essential to choose a shrink wrap that provides adequate puncture resistance and is designed to endure the conditions the packaged items will face during storage and transit.

Another important aspect is the shrink temperature and time required for sealing the wrap correctly. Some materials shrink rapidly at lower temperatures, while others may need a more prolonged heating period to achieve the desired snugness. Understanding the shrinkage characteristics can aid in selecting the right equipment and processes. Additionally, consider the environmental impact of the material, opting for biodegradable or recyclable options when available to align with sustainability goals. Ultimately, these considerations will help in choosing the best shrink wrap solution tailored to specific packaging requirements.

Top 10 Best Shrink Wrap Solutions for Packaging and Protection in 2023

| Shrink Wrap Type | Thickness (Mil) | Shrink Ratio | Material Type | Applications | Temperature Resistance (°F) |

|---|---|---|---|---|---|

| PVC Shrink Wrap | 40 | 2:1 | Polyvinyl Chloride | Retail Packaging, Food Wrap | 180 |

| PE Shrink Wrap | 75 | 3:1 | Polyethylene | Boxing, Bundling | 200 |

| Polyolefin Shrink Wrap | 50 | 2:1 | Polyolefin | General Packaging, Bundling | 250 |

| Multi-Layer Shrink Wrap | 85 | 4:1 | Multi-Layer Film | Heavy Machinery, Palletizing | 300 |

| Heavy-Duty Shrink Wrap | 100 | 2:1 | High-Density Polyethylene | Industrial Equipment, Outdoor Storage | 220 |

| Clear Shrink Wrap | 50 | 2:1 | Polyolefin | Retail Display, Gift Packaging | 220 |

| Colored Shrink Wrap | 75 | 3:1 | Polyvinyl Chloride | Art Supplies, Retail Displays | 180 |

| Shrink Tubing | 40 | 2:1 | Polyethylene | Cable Management, Electrical Installations | 170 |

| Biodegradable Shrink Wrap | 50 | 2:1 | PLA (Polylactic Acid) | Eco-Friendly Packaging, Food Products | 160 |

| Food-Grade Shrink Wrap | 60 | 2:1 | Polyolefin | Food Packaging, Meat and Produce | 240 |

Top 10 Recommended Shrink Wrap Products for Enhanced Protection

When it comes to packaging and protection, shrink wrap solutions offer versatile options that cater to various needs in 2023. These products are designed to provide a tight, secure fit around items, ensuring they are safeguarded from dust, moisture, and physical damage. The effectiveness of shrink wrap lies in its ability to conform to the shape of the product, delivering an aesthetic appeal alongside practical benefits. From industrial uses to personal applications, there are numerous high-quality shrink wrap products that can enhance protection for your items.

For those considering shrink wrap for packaging, it’s essential to select the right type for your specific needs. Some products are recommended for maximum clarity and visibility, while others prioritize strength and durability. When applying shrink wrap, make sure to preheat it appropriately to achieve optimal shrinkage. Additionally, consider using a heat gun for better control over the wrapping process, as it helps to evenly distribute heat and avoid burns or excessive wrinkles.

One key tip is to ensure that the items being wrapped are clean and dry. Any debris or moisture can compromise the protective seal, leading to potential damage over time. Furthermore, if you’re wrapping multiple items, it can be beneficial to group similar ones together to streamline the process and enhance protection efficiency. By incorporating these best practices, you’ll ensure that your shrink wrap solution not only secures your items effectively but also maintains their integrity during storage or transport.

Top 10 Best Shrink Wrap Solutions for Packaging and Protection in 2023

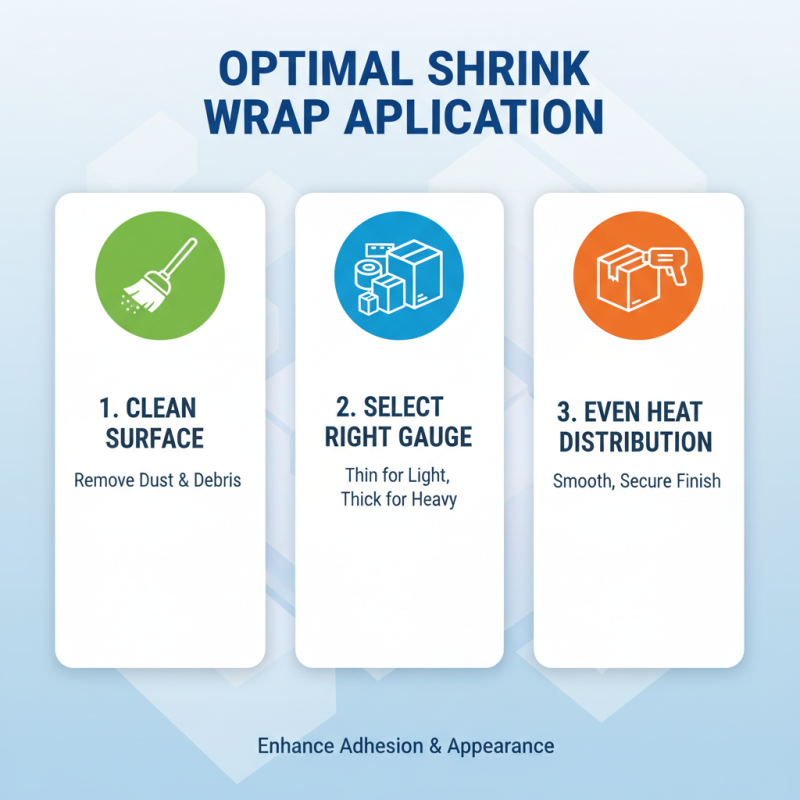

Best Practices for Applying Shrink Wrap Effectively and Efficiently

Effectively applying shrink wrap involves understanding the material and the techniques needed to achieve optimal results. One of the best practices is to ensure that the surface to be wrapped is clean and free of any dust or debris. This not only helps the shrink wrap adhere better but also enhances the finished appearance. Additionally, selecting the right gauge of shrink wrap for the specific package is crucial; thinner wraps are suitable for lighter items, while thicker options provide extra durability for heavier products.

Another essential practice is to apply heat evenly to avoid incomplete adhesion or damage to the product. Using a heat gun or an industrial shrink tunnel can facilitate this process. Starting from the center and moving towards the edges ensures that air is removed efficiently, preventing trapped bubbles. It's also important to maintain an appropriate distance from the heat source to protect both the wrap and the item being packaged. Implementing these techniques will enhance the efficiency of shrink wrapping, ensuring that the products are securely packaged and protected throughout their journey to the end user.

Related Posts

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

Top 10 Benefits of Using a Pallet Spinner in Your Warehouse Operations

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping

-

Why You Need a Carton Erector for Streamlined Packaging Operations

-

2025 Top Trends in Automatic Packing Systems for Improved Efficiency

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper