BLOG

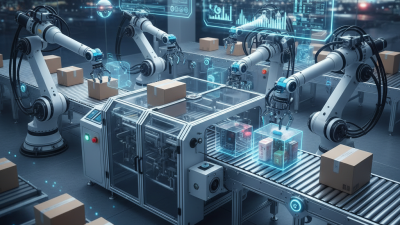

Top Benefits of Using an Automatic Packing System for Your Business

In the fast-paced world of manufacturing and logistics, businesses are continuously seeking innovative solutions to enhance efficiency and reduce operational costs. One such transformative technology is the automatic packing system, which has gained significant traction in recent years. According to a report by Research and Markets, the global automatic packaging market is projected to reach $70 billion by 2025, indicating a compound annual growth rate (CAGR) of approximately 7.8%. This growth is driven by the increasing demand for precision, speed, and scalability in packaging operations.

Industry expert Dr. Jane Thompson, a leading authority on automated processes, emphasizes the vital role of automatic packing systems in modern businesses: "Implementing an automatic packing system not only streamlines workflows but also drastically reduces labor costs and minimizes errors." Her insights reflect a broader trend where companies adopting these advanced systems are able to improve their overall productivity while ensuring consistent quality and customer satisfaction.

As businesses strive to meet the rising consumer demands and navigate the complexities of supply chains, integrating an automatic packing system is becoming increasingly essential. By leveraging this technology, companies can position themselves for growth and success in an increasingly competitive landscape.

Key Advantages of Automatic Packing Systems in Modern Business

Automatic packing systems have revolutionized the way businesses manage their packaging needs, offering a range of advantages that enhance operational efficiency. One of the key benefits is the significant reduction in labor costs. By automating the packing process, companies can diminish the reliance on manual labor, which not only cuts down on expenses but also minimizes human errors often associated with traditional packing methods. This efficiency allows businesses to allocate their workforce to more strategic tasks, ultimately fostering innovation and productivity.

Another crucial advantage is the consistency and quality assurance provided by automatic packing systems. These systems guarantee uniformity in packaging, reducing variability that can lead to product damage or customer dissatisfaction. Advanced technology can also monitor the packaging process in real time, ensuring each item is packed to the same high standards. This reliability builds trust with customers and can enhance brand reputation, making it a vital component for businesses aiming to thrive in competitive markets. By embracing automatic packing solutions, companies position themselves to respond effectively to market demands while maintaining high operational standards.

Enhanced Efficiency: Streamlining Operations with Automation

The adoption of automatic packing systems has become increasingly vital for businesses aiming to enhance operational efficiency. Automation in packing processes not only reduces the time spent on these tasks but also minimizes the risk of human error. According to a report by MarketsandMarkets, the global automated packaging market is projected to grow from USD 45.8 billion in 2020 to USD 65.5 billion by 2025, indicating a robust shift towards automated solutions. This significant growth underscores the growing recognition among businesses of the advantages that automation provides, particularly in streamlining operations.

In a typical manual packing environment, the average packing speed is limited by human capabilities, often ranging between 10 to 20 packages per hour. However, automated systems can increase this output dramatically, achieving speeds of up to 100 packages per hour or more, depending on the technology employed. A study from the Packaging Automation Association highlights that companies implementing automation can see a reduction in labor costs by as much as 30%, allowing for a reallocation of resources to more critical areas of the business. This transformation not only accelerates productivity but also enhances the consistency and quality of packaging, as automated systems typically employ precise measurements and controls that are difficult to replicate manually.

Cost Savings: Reducing Labor and Material Waste in Packing

The implementation of an automatic packing system in businesses has shown significant potential for cost savings through both reduced labor and material waste. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), automating packing processes can reduce labor costs by up to 30%. This reduction is primarily due to the efficiency gains achieved through speedier operations and less reliance on manual tasks, which can be cumbersome and prone to errors. With labor shortages becoming a growing concern in many industries, automation serves as a strategic solution to maintain productivity without escalating labor expenses.

Moreover, the use of automatic packing systems leads to substantial reductions in material waste. Research from Smithers Pira highlights that automated systems can decrease packaging waste by approximately 25%, as they enable precise materials usage tailored to individual product dimensions. This precision not only helps in cutting costs related to raw materials and disposal but also supports sustainability initiatives within companies.

Replacement of traditional packing methods with automated solutions can thus contribute to both financial savings and an environmentally friendly business model, positioning organizations to thrive in an increasingly eco-conscious market.

Improved Accuracy: Minimizing Errors in Packing Processes

An automatic packing system stands at the forefront of modern logistics, particularly when it comes to enhancing accuracy in packing processes. According to industry reports, businesses that implement automatic packing solutions can reduce packing errors by up to 99%. This significant improvement stems from the precision of automated machinery, which eliminates human error commonplace in manual packing. For instance, a study from the Packaging Automation Association revealed that companies transitioning to automated systems experienced drastic decreases in mislabeling and product damages, bolstering overall operational efficiency.

Moreover, the financial implications of improved accuracy are substantial. A 2021 survey by the Warehousing Education and Research Council found that inaccuracies in packing lead to an annual loss of approximately $1 billion across the industry. By utilizing automatic packing systems, companies not only ensure higher accuracy rates but also mitigate the costs associated with returns and re-shipments due to packing errors. This reduction in error margins creates a clearer pathway to customer satisfaction, reinforcing the value of automated solutions in today's competitive market. Ultimately, the integration of automation in packing not only increases accuracy but also enhances the bottom line, enabling businesses to focus on growth and customer service.

Top Benefits of Using an Automatic Packing System for Your Business - Improved Accuracy: Minimizing Errors in Packing Processes

| Benefit | Description | Impact on Errors | Estimated Reduction (%) |

|---|---|---|---|

| Automated Weight Measurement | Ensures the correct weight of packed items to minimize shipping discrepancies. | Reduces manual weighing errors | 30% |

| Barcode Scanning | Utilizes barcode technology to match products with their packing specifications. | Minimizes mispackaged items | 25% |

| Real-time Monitoring | Allows for immediate detection of packing errors during the process. | Allows for quick error corrections | 40% |

| Consistent Packing Standards | Ensures uniform packing sizes and methods across all products. | Reduces variance in packing | 20% |

| Integration with Inventory Systems | Links packing data directly to inventory management, reducing stock errors. | Eliminates discrepancies in stock levels | 35% |

Flexibility and Scalability: Adapting to Business Growth and Demand

In today's fast-paced business environment, flexibility and scalability are crucial for success, particularly when it comes to operations like packaging. An automatic packing system effortlessly adapts to the changing demands of a business. As production volumes fluctuate, such systems can be easily adjusted to handle various package sizes and quantities without the need for extensive reconfiguration. This adaptability enables businesses to respond quickly to market trends, ensuring they remain competitive.

Moreover, as a business grows, its packaging requirements evolve. An automatic packing system is designed to scale alongside business needs, accommodating increased output without sacrificing efficiency or speed. This scalability not only streamlines operations but also helps to manage labor costs effectively. By investing in a packaging system capable of growing with the company, businesses can maintain a focus on quality and customer satisfaction, even during peak periods. Overall, embracing flexibility and scalability through an automatic packing system provides a significant advantage that supports sustained business growth.

Conclusion

An automatic packing system offers a multitude of benefits that can significantly enhance the efficiency and effectiveness of modern businesses. By streamlining operations through automation, these systems not only reduce labor costs but also minimize material waste, resulting in substantial cost savings. Moreover, they improve accuracy in packing processes, thereby decreasing the likelihood of errors and ensuring a consistent quality of packaging.

Additionally, automatic packing systems provide the flexibility and scalability needed to adapt to changing business demands and growth. This adaptability is crucial for meeting varying market needs while maintaining safety standards. Overall, integrating an automatic packing system can lead to improved operational performance and greater competitiveness in the market.

Related Posts

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

2025 Top 5 Automated Packaging Line Innovations Transforming Supply Chains

-

Exploring the Benefits of Shrink Wrap Packaging for Sustainable Business Practices

-

What is a Case Packer and How It Transforms Your Packaging Process

-

2025 Guide to the Best Case Packer Manufacturers for Efficient Packaging Solutions

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency