BLOG

Top 10 Benefits of Using a Carton Erector Machine for Your Business

In the rapidly evolving packaging industry, the demand for efficiency and cost-effectiveness has never been greater. A pivotal innovation in this space is the carton erector machine, which streamlines the process of assembling boxes, thereby increasing productivity and reducing labor costs. According to a recent report by Smithers Pira, the global market for carton forming machinery is projected to grow at a compound annual growth rate (CAGR) of 5.6% from 2021 to 2026, highlighting the increasing reliance on automation in packaging operations.

Industry expert Dr. Jane Thompson, a leading figure in packaging technology, emphasizes the advantages of implementing a carton erector machine, stating, "Adopting automation in carton erecting not only enhances efficiency but also significantly lowers the risk of human error, ensuring a more reliable production process." The strategic use of these machines allows businesses to meet high-volume demands while maintaining consistency and quality. As we delve into the top benefits of utilizing a carton erector machine, it becomes evident that this investment is a crucial step for businesses aiming to stay competitive in a challenging marketplace.

Understanding Carton Erector Machines and Their Functionality

Carton erector machines play a pivotal role in streamlining packaging processes by automating the assembly of cartons, which significantly enhances operational efficiency. According to a report by Smithers Pira, the global market for packaging automation is expected to grow to $70 billion by 2024, reflecting the increasing demand for automated solutions in various industries. These machines are designed to fold and seal cartons quickly and accurately, minimizing labor costs and reducing the likelihood of human error. As a result, businesses can achieve a higher throughput while maintaining product quality.

The functionality of carton erector machines is characterized by their ability to handle a wide range of carton sizes and styles, providing flexibility that is crucial for modern manufacturing. Utilizing advanced technologies such as PLC controls, these machines can be programmed to adapt to different packaging needs on the fly, which is particularly beneficial in industries where product lines frequently change.

According to a study by the Packaging Machinery Manufacturers Institute (PMMI), companies that incorporate carton erectors into their production lines can see efficiency gains of up to 50%, reinforcing their competitiveness in an increasingly fast-paced market. By automating the carton assembly process, manufacturers not only save time but also ensure that their packaging meets the necessary structural integrity for shipping and presentation.

Increased Efficiency: How Carton Erector Machines Optimize Production

Carton erecting machines are revolutionizing the way businesses handle their packaging processes. By automating the assembly of cartons, these machines significantly enhance production efficiency. Traditionally, the task of erecting cartons required manual labor, a time-consuming process that often resulted in inconsistencies and delays. With a carton erector machine in place, businesses can achieve faster setup times, allowing them to adapt quickly to changing production needs and scale operations more effectively.

Moreover, carton erector machines minimize the potential for human error during the packaging process. When cartons are erected automatically, it ensures uniformity in size and shape, which is essential for downstream packing and shipping operations. This consistency not only streamlines the packing workflow but also reduces wasted materials and labor costs. By optimizing various aspects of production, these machines help businesses maintain smoother operations while meeting customer demands with greater speed and accuracy.

Top 10 Benefits of Using a Carton Erector Machine for Your Business

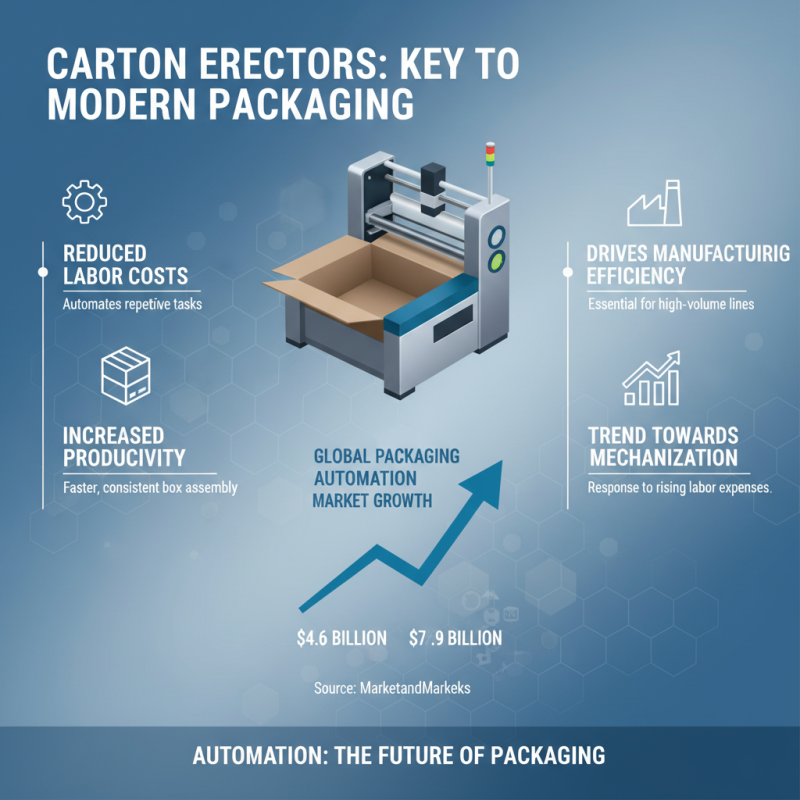

This chart illustrates the advantages of using a carton erector machine in terms of efficiency, time savings, and labor reduction in production processes.

Cost Savings: The Financial Benefits of Automated Carton Erection

Automated carton erector machines offer significant cost savings that can directly impact the bottom line of any business involved in packaging. By streamlining the carton erection process, these machines reduce labor costs, minimize material waste, and enhance production speed.

Companies can allocate their resources more effectively, allowing them to focus on core business functions rather than manual bottlenecks often associated with traditional packaging methods. The reduction in the need for manual labor not only lowers payroll expenses but also minimizes the potential for human error, which can lead to costly rework or product damage.

Tips: To maximize the financial benefits of using a carton erecting machine, conduct a thorough analysis of current packing costs. Assess labor expenses, downtime, and material waste. Implementing an automated system with precise carton sizing can greatly reduce the amount of material used, further enhancing your savings.

Moreover, automated machines often have a quick return on investment (ROI). By speeding up the packing process, businesses can increase their throughput, fulfilling customer demands more efficiently. Investing in a carton erector not only boosts productivity but also allows for scalability, making it easier to adapt to growing business needs without incurring proportional increases in labor costs.

Tips: Consider evaluating different automation options and select a solution that can be integrated with your existing systems, keeping in mind both initial investment and long-term savings potential. Proper training for employees on new equipment can also play a crucial role in achieving optimal efficiency and maximizing the financial benefits.

Enhanced Consistency and Quality in Packaging Operations

In today's competitive market, the importance of consistent and high-quality packaging operations cannot be overstated. Utilizing a carton erecting machine significantly enhances these aspects by automating the process of creating and assembling cartons. According to a report by Smithers Pira, the packaging machinery market is projected to grow at a compound annual growth rate (CAGR) of 4.4% from 2020 to 2025. As businesses strive to meet increasing consumer demands while maintaining operational efficiency, carton erectors play a crucial role in optimizing packaging consistency.

Automated carton erecting not only improves speed but also ensures uniformity in carton dimensions, which is critical for downstream packaging processes. The International Journal of Packaging Technology and Science highlights that discrepancies in carton quality can lead to increased product damage during transportation, resulting in costs as high as $1.5 trillion annually in lost goods. By using a carton erector machine, companies can reduce variability, mitigate the risk of such damage, and maintain a high standard of packaging quality.

Moreover, enhanced consistency in packaging operations allows for better adherence to regulatory standards and consumer expectations. A report by the Packaging Machinery Manufacturers Institute indicates that automation can improve overall productivity by up to 30%, further solidifying the competitive edge of businesses. By investing in carton erectors, companies not only streamline their operations but also establish a reputation for reliability and quality in their packaging processes.

The Role of Carton Erector Machines in Reducing Labor Costs

Carton erectors have become increasingly pivotal in modern manufacturing and packaging processes, primarily due to their significant role in reducing labor costs. The demand for efficient packaging solutions has led many businesses to adopt automation technologies, with carton erector machines at the forefront. According to a report by MarketsandMarkets, the global packaging automation market is projected to grow from $4.6 billion in 2020 to $7.9 billion by 2025, highlighting a robust trend toward mechanization in response to rising labor costs and the need for increased productivity.

By utilizing a carton erector machine, companies can streamline the process of forming cartons, which traditionally required manual labor. Studies have shown that automating this task can reduce labor requirements by up to 30%, translating directly into substantial cost savings. In an industry where labor costs continue to escalate—estimated to account for 70% of total operating costs in some sectors—implementing a carton erector can be a strategic move. Additionally, these machines increase operational efficiency, allowing businesses to reallocate human resources to more value-added tasks rather than repetitive manual work. As such, understanding and leveraging the capabilities of carton erector machines is critical for businesses aiming to maintain a competitive edge in an ever-changing labor market.

Related Posts

-

Why You Need a Carton Erector for Streamlined Packaging Operations

-

2025 Guide to the Best Case Packer Manufacturers for Efficient Packaging Solutions

-

Revolutionizing Efficiency in Automated Packaging Solutions for Modern Businesses

-

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

-

Top 10 Benefits of Using Pallet Wrap in Warehousing and Logistics

-

Revolutionizing Warehouse Efficiency: The Science Behind Automatic Pallet Wrappers