BLOG

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

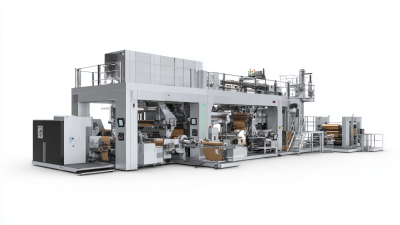

In today's fast-paced manufacturing and packaging environments, efficiency is paramount. One of the key innovations that has significantly enhanced packaging processes is the shrink tunnel machine. This equipment utilizes heat to shrink plastic film tightly around products, providing a secure and visually appealing package.

The shrink tunnel machine not only maximizes product protection during transit but also minimizes packaging waste, promoting sustainability. Additionally, its high-speed operation allows businesses to increase throughput, meet growing consumer demands, and maintain a competitive advantage in the market.

As we explore the benefits of using a shrink tunnel machine, it becomes evident that this technology is integral to improving packaging efficiency, ensuring that products are not only safe but also presented in an attractive manner.

The shrink tunnel machine not only maximizes product protection during transit but also minimizes packaging waste, promoting sustainability. Additionally, its high-speed operation allows businesses to increase throughput, meet growing consumer demands, and maintain a competitive advantage in the market.

As we explore the benefits of using a shrink tunnel machine, it becomes evident that this technology is integral to improving packaging efficiency, ensuring that products are not only safe but also presented in an attractive manner.

Understanding the Functionality of a Shrink Tunnel Machine in Packaging Processes

A shrink tunnel machine plays a crucial role in enhancing the efficiency of packaging processes. By utilizing heat to shrink film tightly around products, these machines ensure a secure and protective packaging solution. This functionality is particularly beneficial in industries dealing with a high volume of items, as the machine streamlines operations, reduces manual labor, and minimizes material waste. The automatic sealing and consistent application of heat results in superior seal integrity, which is vital for maintaining the freshness and quality of food products.

Recent advancements in packaging technology further emphasize the importance of shrink tunnel machines. Many companies are investing in these innovations to keep pace with evolving market demands and regulatory frameworks, such as the EU's Packaging and Packaging Waste Regulation. As companies seek to improve productivity and sustainability, the transition to shrink-film packaging has shown remarkable benefits, including enhanced speed and reduced operational costs.

With the global wrapping machine market set to experience significant growth, understanding the functionality of shrink tunnel machines becomes essential for businesses aiming to improve their packaging processes and meet competitive pressures.

Key Advantages of Implementing Shrink Tunnel Machines for Operational Efficiency

Shrink tunnel machines offer numerous advantages that significantly enhance operational efficiency in packaging processes. One of the primary benefits is the ability to streamline production lines. These machines apply heat to shrink film wrapped around products, creating a tight, secure package. This not only improves the appearance of the products but also minimizes the risk of damage during transportation. As a result, businesses can achieve faster packaging times, reducing bottlenecks in the production line and optimizing labor resources.

Another key advantage of implementing shrink tunnel machines is the enhancement of product protection. The snug fit achieved through shrink wrapping helps safeguard items against moisture, dust, and other potential contaminants. This is especially crucial for manufacturers in industries such as food and beverage, pharmaceuticals, and cosmetics, where maintaining product integrity is vital. Furthermore, the automated nature of shrink tunnel machines reduces the need for manual labor, leading to fewer human errors and improved consistency in packaging quality, ultimately contributing to higher customer satisfaction.

Step-by-Step Guide to Setting Up a Shrink Tunnel Machine for Optimal Results

Setting up a shrink tunnel machine requires careful attention to detail to achieve optimal packaging results. Begin by positioning the machine on a stable, level surface, ensuring that there is adequate space for both operation and maintenance. Proper electrical connections are essential; ensure the machine is wired according to the manufacturer’s specifications to prevent any interruptions during operation. After connecting the power supply, perform a thorough check to ensure all components are securely fastened and correctly aligned.

Next, adjust the conveyor speed and temperature settings based on the materials being processed. Generally, thinner films require lower temperatures and faster speeds, while thicker materials might need higher temperatures for effective shrinking. Run a series of test packages to fine-tune these settings. Monitor the output for consistency in the seal and overall appearance, adjusting parameters as necessary. Finally, establish a routine for regular maintenance and cleaning of the shrink tunnel to maintain efficiency and prolong the machine's lifespan. This step-by-step approach will ensure that you maximize the benefits of the shrink tunnel machine, enhancing your packaging efficiency.

Exploring the Benefits of Using a Shrink Tunnel Machine for Enhanced Packaging Efficiency

| Dimension | Description | Benefits |

|---|---|---|

| Speed | Efficiency of packaging process | Increased production rates and reduced labor |

| Cost Savings | Reduction in packaging materials | Lower material costs and waste reduction |

| Product Protection | Secure sealing of products | Minimized damage during transport |

| Versatility | Ability to package various shapes and sizes | Adaptability to different products and requirements |

| Setup Time | Initial setup for operation | Quick and easy installation process |

Enhancing Product Protection and Shelf Life with Shrink Tunnel Technology

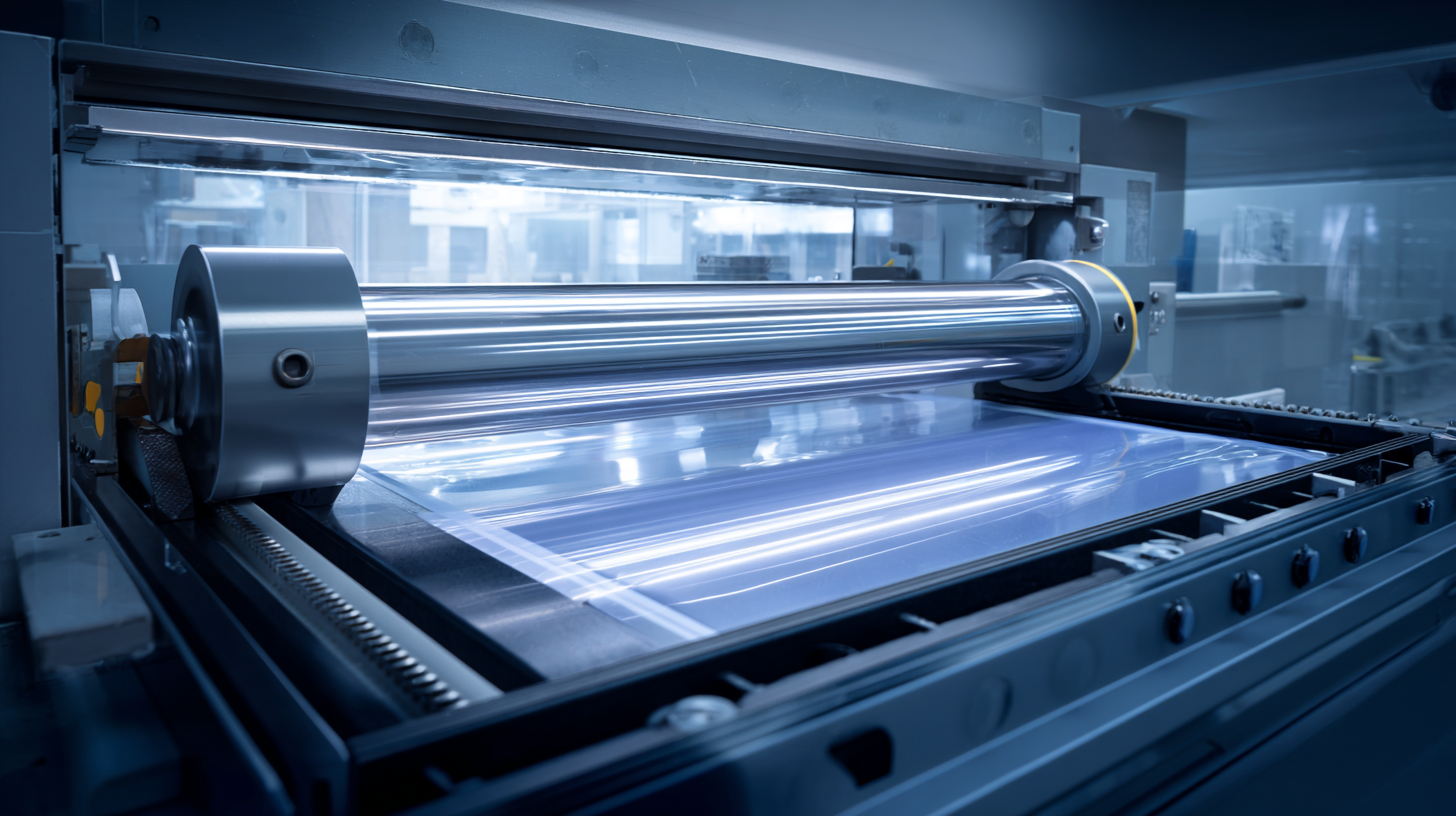

Shrink tunnel technology has revolutionized packaging processes by providing significant enhancement in product protection and shelf life. By tightly wrapping products in a plastic film that conforms to their shape, shrink tunnel machines create a barrier against moisture, dust, and other environmental factors. According to a report by Smithers Pira, the global demand for flexible packaging is projected to reach $200 billion by 2025, underscoring the importance of efficient packaging solutions in the modern market.

One of the key benefits of using shrink tunnels is the increased durability of packaged goods. Products that are shrink-wrapped not only retain their quality for longer periods but also experience fewer damages during transit. A study from the Packaging Association revealed that companies utilizing shrink wrap see a reduction in damage costs by up to 20%. This increased protection is particularly beneficial for perishable items, ensuring that they maintain freshness and appeal to consumers.

Tips: To maximize the benefits of shrink tunnel packaging, ensure that the film used is of high quality and suits the specific product requirements. Regular maintenance of the shrink tunnel machine is also crucial to prevent breakdowns and ensure consistent performance, enhancing overall packaging efficiency.

Cost-Effectiveness of Shrink Tunnel Machines in Modern Packaging Solutions

The cost-effectiveness of shrink tunnel machines has become increasingly apparent in modern packaging solutions. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $53.2 billion by 2025, with shrink wrapping technology leading this growth due to its efficiency and affordability. Shrink tunnel machines not only streamline the packaging process but also significantly reduce material costs. By utilizing shrink films that conform tightly to products, companies can minimize wastage and maximize product visibility, which is crucial for retail settings.

Furthermore, the operational efficiency of shrink tunnel machines translates into lower labor costs. Industry analysis by PMMI indicates that automated packaging solutions can enhance production speed by 30% compared to manual methods. This increased throughput allows companies to meet rising consumer demands without compromising on quality. Moreover, with a growing focus on sustainability, the use of shrink tunnels aligns with eco-friendly practices, as they often require fewer resources and generate less waste. Consequently, investing in shrink tunnel technology not only improves efficiency but also contributes to overall cost savings and sustainable growth in the packaging sector.