BLOG

Top 10 Benefits of Using a Lantech Stretch Wrapper for Your Packaging Needs

In the ever-evolving landscape of packaging solutions, efficiency, and reliability play critical roles in meeting the demands of modern supply chains. The use of stretch wrapping has emerged as a preferred method for securing products, with the Lantech stretch wrapper standing out among the options available on the market. According to the Packaging Machinery Manufacturers Institute (PMMI), the packaging machinery industry is expected to grow substantially, with a projected CAGR of 4.5% through 2026. This growth highlights the increasing importance of investing in high-quality equipment like the Lantech stretch wrapper to optimize efficiency and ensure product integrity during transportation.

Modern businesses recognize that the right packaging not only enhances product safety but also reduces waste and costs. Reports from the Freedonia Group indicate that the demand for stretch wrapping machinery is projected to rise significantly, driven by advancements in technology and the need for more sustainable packaging solutions. By integrating a Lantech stretch wrapper into packaging operations, companies can benefit from enhanced productivity, reduced film consumption, and improved load stability, thereby aligning with industry trends and maximizing operational effectiveness.

As organizations continuously seek ways to improve efficiency and reduce operational costs, the advantages of using a Lantech stretch wrapper become increasingly apparent. This introduction serves to illuminate the top ten benefits of adopting this technology, reinforcing its role in enabling businesses to thrive in a competitive marketplace while adhering to evolving industry standards.

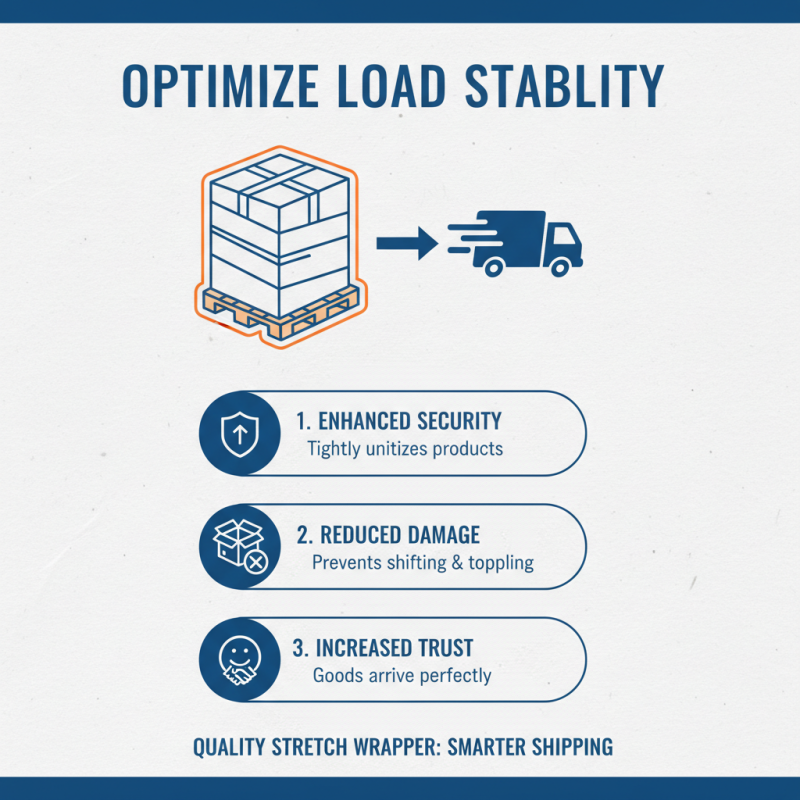

Benefits of Increased Load Stability with Lantech Stretch Wrappers

When it comes to packaging solutions, load stability is a crucial factor that directly impacts the efficiency of transportation and storage. Utilizing a quality stretch wrapper enhances the stability of loads by tightly securing products together, minimizing the risk of shifting or toppling during transit. This enhanced stability reduces product damage and ensures that goods arrive at their destination in optimal condition, ultimately leading to higher customer satisfaction and trust.

Additionally, increased load stability achieved through stretch wrapping can lead to significant cost savings. By preventing product movement and damage, companies can minimize waste and reduce the need for excessive padding or additional protective measures during shipping. Moreover, well-wrapped loads optimize space in transportation and storage, allowing businesses to maximize their logistical efficiency. This understanding highlights the importance of investing in reliable wrapping solutions to maintain load integrity throughout the supply chain, ensuring products remain safe and secure from the warehouse to the end user.

Enhancing Product Protection Through Lantech Stretch Wrapping Technology

When it comes to packaging, the protection of products during transit is paramount. Lantech stretch wrapping technology offers innovative solutions that enhance product safety and minimize damage. This wrapping process utilizes durable stretch film that tightly adheres to products, creating a secure and stable load that withstands the rigors of shipping and handling. By employing this technology, businesses can significantly reduce the likelihood of product breakage, ensuring that items arrive at their destination in pristine condition.

One key tip for maximizing the benefits of stretch wrapping is to ensure the proper tension is applied to the film. Too much tension can cause the film to tear or the load to shift, while too little tension can lead to insufficient protection. Additionally, consider utilizing corner protectors or dunnage during the wrapping process to further enhance load stability. These simple practices can drastically improve the effectiveness of your packaging, leading to greater customer satisfaction and reduced return rates.

Another effective strategy is to conduct regular maintenance on your wrapping equipment. By keeping machinery in optimal condition, you can improve the quality of your wraps and ensure consistent performance. Training your staff on the correct techniques for operating stretch wrapping machines can also lead to better wrapping outcomes, minimizing the chances of damage during transportation. Implementing these tips can significantly contribute to a more efficient and reliable packaging operation.

Top 10 Benefits of Using a Lantech Stretch Wrapper for Your Packaging Needs

| Benefit | Description |

|---|---|

| Improved Load Stability | Ensures that products remain securely bundled, reducing the risk of shifting during transport. |

| Cost Efficiency | Lowers packaging material costs by optimizing film usage through advanced wrapping technology. |

| Reduced Labor Costs | Automates wrapping processes, minimizing manual labor and the associated costs. |

| Enhanced Product Protection | Provides a tight seal that protects products from environmental factors and damage. |

| Consistency and Quality | Delivers uniform wrapping, ensuring that products are consistently packaged to high standards. |

| Faster Turnaround Time | Streamlines the packing process, enabling quicker shipping and delivery schedules. |

| Versatility in Packaging | Suitable for a variety of product shapes and sizes, increasing the range of applications. |

| Space Efficiency | Compact design allows for use in tight spaces, optimizing warehouse usage. |

| Enhanced Safety | Reduces the risk of product damage and safeguards workforce safety during the packing process. |

| User-Friendly Operation | Features intuitive controls and setups that facilitate easy training for staff. |

Reducing Packaging Material Costs with Lantech Solutions

Using a stretch wrapper can drastically reduce packaging material costs, an essential consideration for manufacturers and distributors looking to improve efficiency and sustainability. According to a recent report from the Flexible Packaging Association, businesses that implement stretch wrapping solutions can decrease their packaging film usage by up to 50%. This reduction not only minimizes waste but also leads to significant savings on material expenses. By utilizing advanced stretch technology, companies can optimize the amount of film applied per load, ensuring that every shipment is securely wrapped while consuming less material overall.

Additionally, the adoption of innovative stretch wrapping equipment helps streamline operations and lowers the overall cost of packaging processes. A study by the Packaging Machinery Manufacturers Institute found that automated stretch wrappers can enhance packaging speed by up to 30%, which translates directly to reduced labor costs. With faster wrapping solutions, organizations can scale their production without necessitating a proportional increase in labor, allowing for a more efficient allocation of resources. The cumulative effect of these efficiencies leads to a remarkable decrease in the total packaging costs, providing businesses with a competitive edge in a cost-sensitive marketplace.

Improving Warehouse Efficiency with Automated Stretch Wrapping

Automated stretch wrapping has become a game-changer in the logistics and warehousing sector, significantly enhancing efficiency and productivity. According to industry studies, the implementation of automated stretch wrappers can reduce packaging time by up to 50%, allowing for quicker shipment and turnover. This improvement is essential for businesses looking to meet the growing demands of a fast-paced market.

Additionally, automated systems minimize manual labor, which not only lowers labor costs but also reduces the risk of workplace injuries associated with repetitive wrapping tasks.

For warehouses aiming to optimize their operations, incorporating a stretch wrapper can dramatically improve load stability during transportation. An effective stretch wrapping machine consistently applies the right amount of tension, which holds pallets securely in place. This not only decreases the chances of product damage but also enhances safety during transit. Research indicates that properly wrapped loads can reduce damage claims by up to 30%, encouraging a smoother supply chain process.

Tips: When considering automated stretch wrapping, always assess your specific packaging needs. Select a machine that offers adjustable settings for different load sizes to ensure versatility. It's also crucial to invest in quality stretch film that adheres well and provides reliable protection against environmental factors. Regular maintenance of the wrapping equipment can prevent breakdowns and maintain efficiency in the long run.

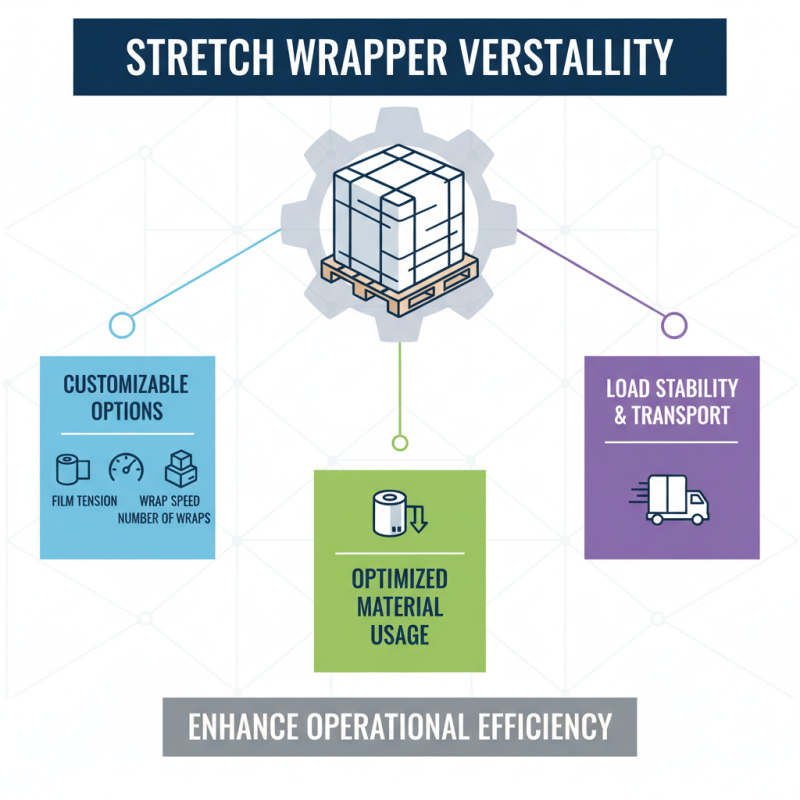

Customizable Options and Features of Lantech Stretch Wrappers

When considering packaging solutions, the versatility of stretch wrappers can significantly enhance operational efficiency. These machines come equipped with customizable options that cater to various packing needs, ensuring the right fit for different products and pallet configurations. Users can adjust settings for film tension, wrap speed, and number of wraps, which allows for tailored applications from light to heavy-duty packaging. This flexibility not only optimizes material usage but also enhances the stability of the load during transportation.

In addition to adjustable parameters, many stretch wrappers offer advanced features such as automatic film delivery systems and user-friendly interfaces. These innovations streamline the wrapping process, minimize waste, and reduce labor costs. Enhanced security features, such as integrated sensors, help monitor load integrity and ensure that each package is wrapped to the highest standard. This level of customization ensures that businesses can achieve their specific packaging goals while maintaining consistency and quality throughout their operations.

Related Posts

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper

-

What is Pallet Wrap? Understanding Its Uses and Benefits for Shipping

-

Top 10 Benefits of Using Pallet Wrap in Warehousing and Logistics

-

2025 Top Trends in Automatic Packing Systems for Improved Efficiency

-

Revolutionizing Warehouse Efficiency: The Science Behind Automatic Pallet Wrappers

-

How to Choose the Right Palletizer Machine for Your Warehouse Needs