BLOG

2025 Top Trends in Automatic Packing Systems for Improved Efficiency

As businesses continue to evolve in the face of increasing demand for efficiency and speed, the role of automatic packing systems has never been more crucial. Industry experts like Dr. Emily Roberts, a leading authority in supply chain automation, emphasize the importance of these technologies in driving productivity. She states, "The integration of advanced automatic packing systems is transforming how we approach packaging, allowing for seamless scalability and significant cost savings."

In 2025, the trends shaping automatic packing systems will reflect a compelling shift toward greater automation and intelligence. Companies are embracing sophisticated algorithms, AI-driven processes, and robotics that promise to streamline operations and enhance precision. The impacts of these developments extend beyond mere efficiency; they also contribute to sustainability goals by minimizing waste and optimizing materials usage.

As markets demand faster turnaround times and customized solutions, understanding the emerging trends in automatic packing systems becomes imperative for businesses seeking to maintain competitiveness. This introduction highlights the critical evolution of packing technologies that are set to redefine industry standards, pushing boundaries beyond traditional packaging methods.

Emerging Technologies in Automatic Packing Systems for 2025

As we approach 2025, the landscape of automatic packing systems is being transformed by emerging technologies that prioritize efficiency and sustainability. Advanced robotics, integrated with artificial intelligence, will enhance the precision of packing operations, allowing for real-time adjustments based on product variations and order requirements. These intelligent systems will not only reduce human error but also minimize waste through optimized packing processes. The use of machine learning algorithms will enable these systems to learn from previous packing patterns, thus continually improving their efficiency and reducing cycle times.

In addition to robotics, the incorporation of IoT (Internet of Things) technologies will revolutionize how packing systems operate and communicate. By enabling machines to connect and share data, businesses will gain insights into performance metrics, predictive maintenance, and supply chain dynamics. This connectivity will lead to more responsive and adaptive packing solutions, capable of adjusting on-the-fly to consumer demands and inventory levels. Furthermore, advancements in sustainable materials will complement these technologies, as companies seek eco-friendly packing solutions that do not compromise on efficiency. The convergence of these emerging technologies promises to redefine packing systems, aligning them more closely with the modern demands of speed, flexibility, and sustainability in logistics.

Integration of AI and Machine Learning in Packing Automation

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into automatic packing systems is set to revolutionize the packaging industry by enhancing efficiency and reducing operational costs. According to a report by MarketsandMarkets, the global market for AI in packaging is projected to grow from $1.1 billion in 2021 to $4.5 billion by 2025, indicating a compound annual growth rate (CAGR) of 32%. This growth is driven by the need for improved precision in packaging processes, which AI and ML technologies can significantly contribute to by analyzing vast amounts of data and optimizing packing strategies.

AI-driven systems can predict demand fluctuations and adjust packing operations in real-time, thus minimizing waste and ensuring timely deliveries. For instance, predictive maintenance powered by machine learning algorithms can identify potential issues in packing machinery before they lead to costly downtimes. This proactive approach further enhances overall productivity and efficiency in packing operations.

Tips for embracing AI and ML in packing automation include investing in training programs for employees to understand new technologies, conducting pilot tests to assess the effectiveness of AI systems, and staying updated with the latest advancements in automated technologies. By doing so, organizations can not only enhance their operational efficiency but also stay competitive in an increasingly automated market.

Sustainable Practices and Eco-Friendly Materials in Packing Systems

As the packaging industry evolves, the focus on sustainability and eco-friendly materials in automatic packing systems has intensified. According to a report by Smithers Pira, the global market for sustainable packaging materials is projected to reach $300 billion by 2025, highlighting a significant shift towards greener alternatives. Companies are increasingly adopting biodegradable plastics, recycled materials, and reusable containers to reduce their environmental footprint. These innovations not only help in minimizing waste but also appeal to increasingly eco-conscious consumers, driving a demand for sustainable packaging solutions.

Incorporating sustainable practices into automatic packing systems also enhances operational efficiency. For instance, research by the Packaging Machinery Manufacturers Institute (PMMI) indicates that eco-friendly materials can often lead to a reduction in production costs due to their lightweight nature and efficiency in transportation. Moreover, the integration of advanced technologies such as Artificial Intelligence and IoT in packing systems allows for real-time monitoring and optimization of resources, further supporting sustainability goals while maintaining higher throughput. As a consequence, businesses not only contribute positively to the environment but also potentially increase their profit margins through reduced waste and operational savings.

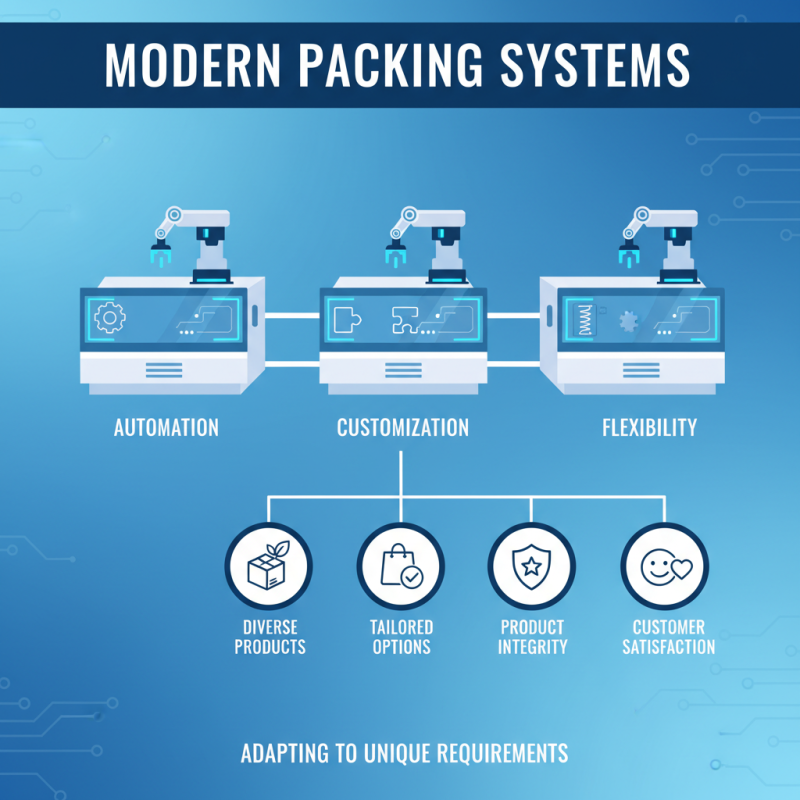

Customization and Flexibility in Packing Solutions for Diverse Products

The modernization of automatic packing systems is paving the way for unprecedented customization and flexibility in packing solutions. As manufacturers increasingly cater to diverse products, the ability to adapt packing processes to meet unique requirements has become vital. Customized packing solutions allow businesses to enhance brand identity while ensuring that products are presented in the most appealing way. This adaptability not only helps in maintaining product integrity but also improves customer satisfaction by providing tailored packaging options.

Flexibility in packing systems enables companies to respond swiftly to market changes and varying customer demands. Automated systems equipped with advanced technology can easily switch between different packing formats and sizes, facilitating a more agile production line. This feature is particularly important in industries with a wide range of products, as it allows for the seamless integration of new items into existing packing workflows. By embracing these trends, businesses can optimize their operations, reduce waste, and ultimately drive efficiency, ensuring they remain competitive in an ever-evolving marketplace.

Impact of Robotics on Packing Efficiency and Labor Dynamics

The integration of robotics into automatic packing systems is revolutionizing efficiency in logistics and manufacturing sectors. According to the "2023 Global Robotics Report", the utilization of robotic technologies in the packing industry has increased productivity by an average of 34%. As parameters of efficiency shift, the roles of human labor are also evolving, emphasizing the necessity for reskilling and enhanced collaboration between human operators and robotic systems.

The introduction of persistent robotic solutions minimizes errors associated with human labor, which, as cited in the "Industry Labor Dynamics Review", leads to a reduction in packing time by up to 25%. Additionally, labor dynamics are undergoing significant transformation; a projected 60% of the workforce will need to adapt to new technology-driven roles by 2025. This shift not only enhances operational capabilities but also frees up human resources for more complex tasks that require critical thinking and creativity, ultimately leading to a smarter, more efficient packing process.

Related Posts

-

The Future of Food Safety Revolutionizing Automated Food Packaging Systems

-

How to Choose the Best Case Packaging for Your Products Efficiently

-

The Future of Sustainable Packaging Equipment Innovations for Eco Friendly Solutions

-

Revolutionizing Efficiency in Manufacturing with an Automated Packaging Line for Sustainable Growth

-

The Ultimate Guide to Understanding the Benefits of an Automatic Pallet Wrapper

-

Top 10 Benefits of Using Pallet Wrap for Secure and Efficient Shipping